Steam valve with rotary bubble breaker

A steam valve and foam-breaking technology, which is applied in the field of kitchen appliances, can solve problems such as unsatisfactory foam-breaking effect, low foam-breaking efficiency, and unstable operation, and achieve good anti-overflow effect, stable foam-breaking effect, and good foam-breaking effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

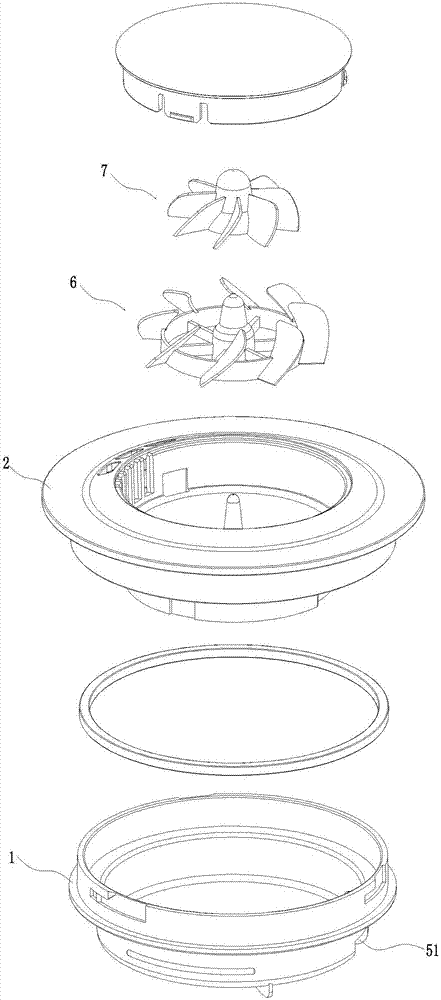

[0036] Such as figure 1 As shown, the first rotating bubble breaking member 6 and the second rotating foam breaking member 7 are nested, and the central axes of the two are coincident. The first rotating foam breaking member 6 and the second rotating foam breaking member 7 are nested, occupying a small space and not affecting the compactness of the steam valve structure. After nesting, the central axis of the two coincides, the airflow interference received during rotation is small, and the foam breaking effect is better.

[0037] The nesting can be partial nesting or full nesting, that is, the second rotating bubble breaking member 7 is at least partially located in the accommodation cavity formed by the first rotating bubble breaking member 6 .

[0038] Such as figure 1 The shown first rotating foam breaking member 6 and the second rotating foam breaking member 7 are horizontally nested, that is, the first rotating foam breaking member 6 and the second rotating foam breaki...

Embodiment 2

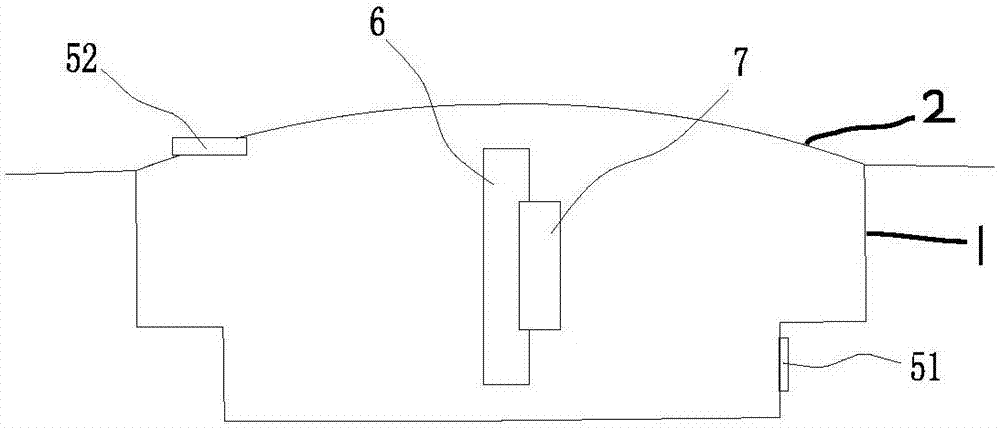

[0042] Such as image 3 As shown, in this embodiment, the first rotating foam breaking member 6 and the second rotating foam breaking member 7 are both arranged horizontally, and both the first rotating foam breaking member 6 and the second rotating foam breaking member 7 can be positioned at The steam ejected from the steam inlet 51 is driven to rotate horizontally. The second rotating bubble breaking member 7 is located above the first rotating bubble breaking member 6, and the central axes of the two are coincident. The two rotating bubble breakers are installed independently. The first rotating bubble breaker 6 may be installed on the valve seat 1 (not shown in the figure), and the second rotated bubble breaker 7 may be installed on the valve cover 2 (not shown in the figure). shown), reduces the requirements on the machining accuracy of the two rotating bubble breaking parts, even if there is a machining accuracy error, it will not affect the assembly, and the wind gene...

Embodiment 3

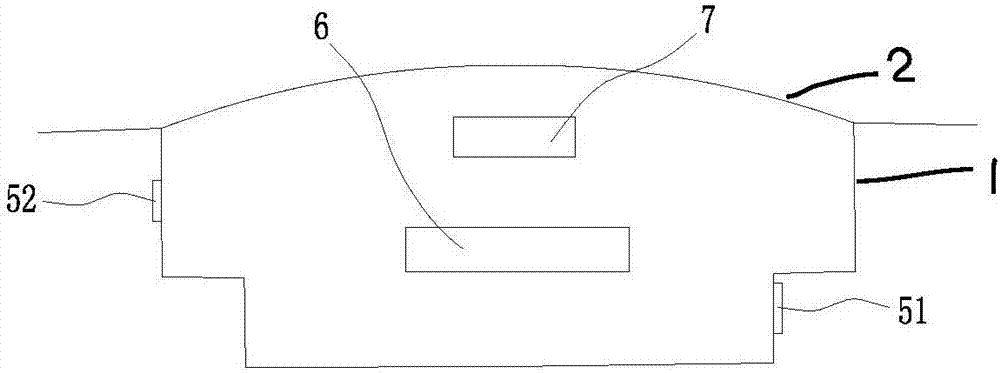

[0045] Such as Figure 4 As shown, in this embodiment, the first rotating foam breaking member 6 and the second rotating foam breaking member 7 are both arranged horizontally, and both the first rotating foam breaking member 6 and the second rotating foam breaking member 7 can be positioned at The steam ejected from the steam inlet 51 is driven to rotate horizontally. The two rotating bubble breakers are arranged horizontally side by side. The two rotating bubble breakers are installed independently. The first rotating foam breaking member 6 can be installed on the valve seat 1 or on the valve cover 2 (not shown in the figure), and the second rotating foam breaking member 7 can also be installed Installed on the valve seat 1 or on the valve cover 2 (not shown in the figure), the requirements for machining accuracy of the two rotating bubble breaking parts are reduced, even if there is an error in machining accuracy, the assembly will not be affected. Moreover, when the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com