A test device and method for measuring the flow coefficient of the inlet hole of the flame cylinder

A technology of flow coefficient and test device, which is applied in the direction of detecting fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effect, etc., can solve the problems of complex test device, cumbersome test process, and decreased accuracy of flow coefficient data, etc. Achieve the effect of improving measurement accuracy, improving test accuracy and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

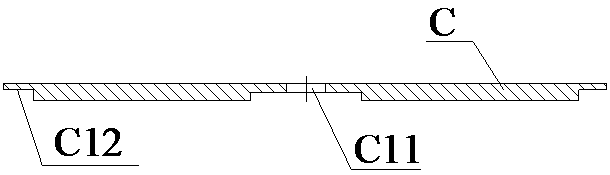

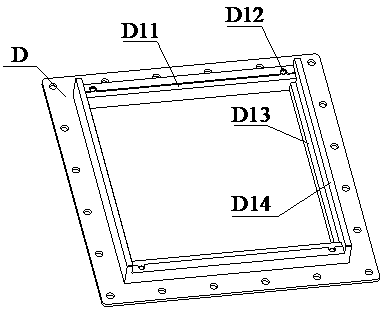

[0029] Such as image 3 As mentioned above, the test device for measuring the flow coefficient of the inlet hole of the flame tube is mainly composed of 1 piece of measuring section assembly A, 1 piece of exhaust assembly B, 1 piece of air inlet orifice plate C, 1 piece of support frame D, and 1 piece of rubber gasket E , 1 piece of rubber gasket F, and 2 pieces of pad K.

[0030]The measuring section component A is a rectangular channel structure, and the middle part of the measuring section component A is provided with a rectangular opening. The exhaust component B is a cylinder structure. The air intake end is a rectangular opening, and the support frame D is a plate-shaped opening structure. The support frame D is set between the rectangular opening in the middle of the measurement section component A and the air intake end of the exhaust component B. There is a place in the middle of the support frame D that can be placed The rectangular hollow of the air inlet orifice p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com