Structure health monitoring software platform realization method based on fiber sensor

An optical fiber sensor and software platform technology, applied in instruments, measurement devices, etc., can solve the problems of program function expansion, poor portability, poor secondary development, and lack of monitoring structural cracks and strains to achieve applicability and operability. Strong performance, convenient for subsequent development, good secondary development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

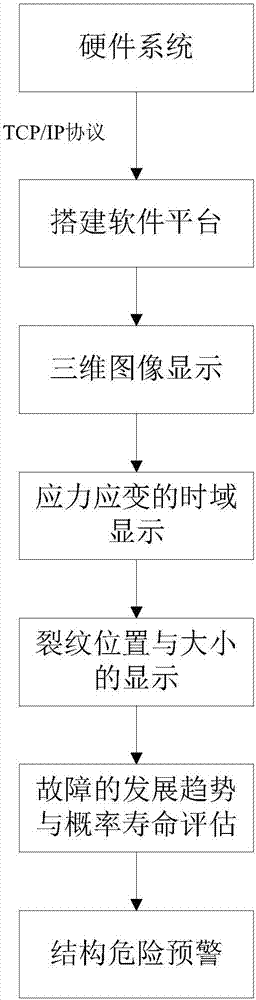

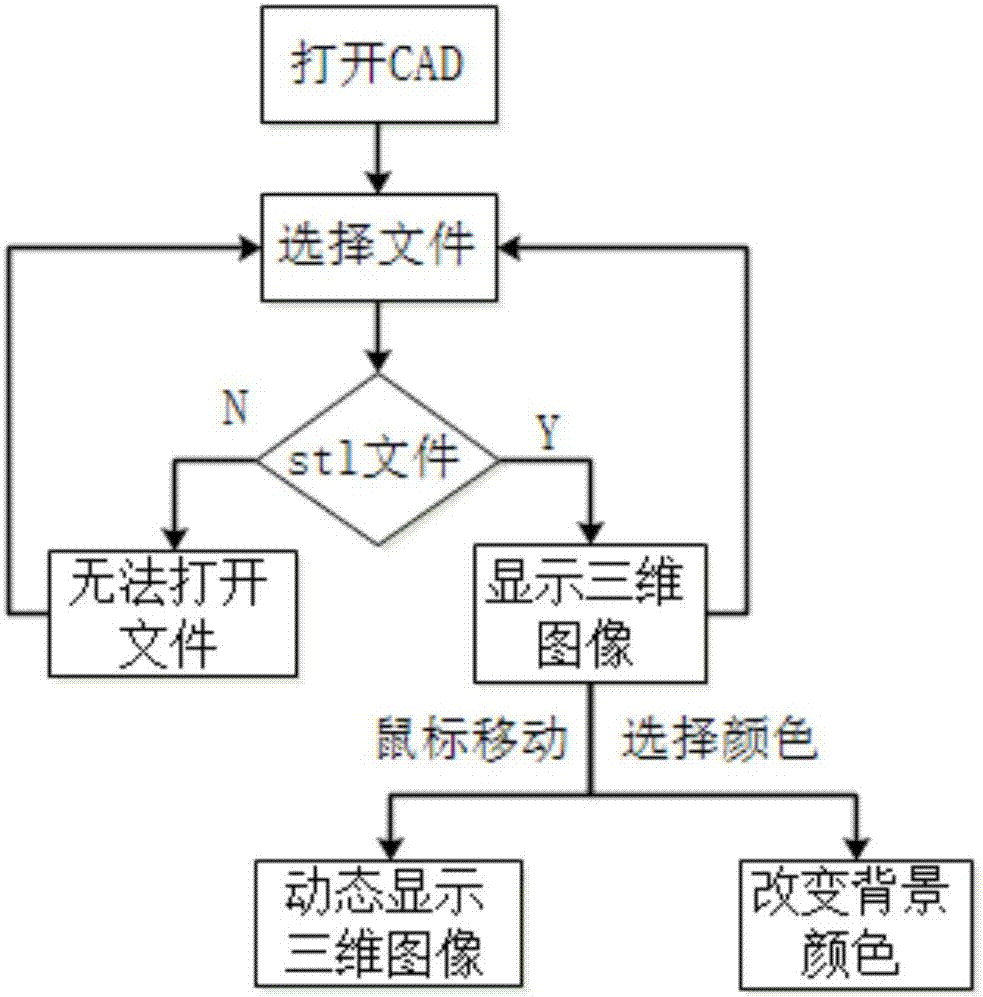

[0036] The present invention is based on the implementation method of the optical fiber Bragg grating sensor structure health monitoring software platform, such as figure 1 As shown, the specific steps are as follows:

[0037] Step 1, at first determine programming language, the present invention uses Microsoft C / C++ compiler version 6.0 (being VC++6.0) to carry out the writing of program, build programming environment on this basis, utilize MFC programming environment, set up dialog box project;

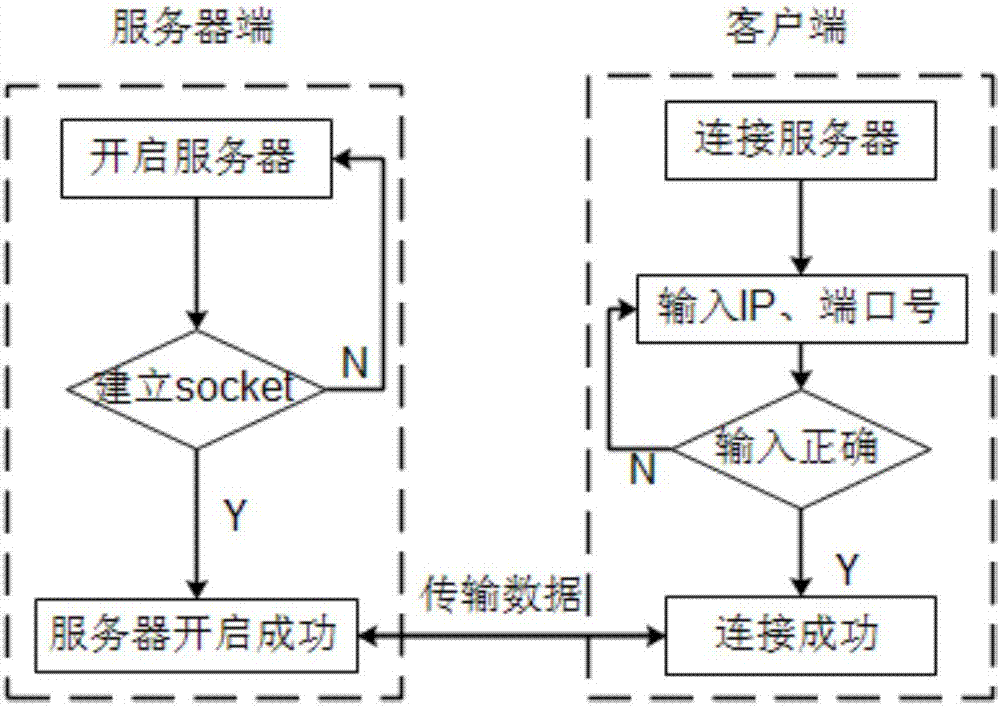

[0038] Step 2: The software platform acts as the server, creates a Socket after opening the server, and connects with the customer service end. If the connection fails, the server is restarted. If the connection is successful, the processed center wavelength information about the measured grid point is received. . The process of opening the server side of the software platform of the TCP / IP protocol, connecting the client side of the hardware platform, and transmitting data between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com