Steel pipe column with large diameter and thick wall and manufacturing method thereof

A technology of steel pipe column and large diameter, which is applied in the field of steel structure and can solve the problems of affecting performance and weak support performance of steel pipe column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

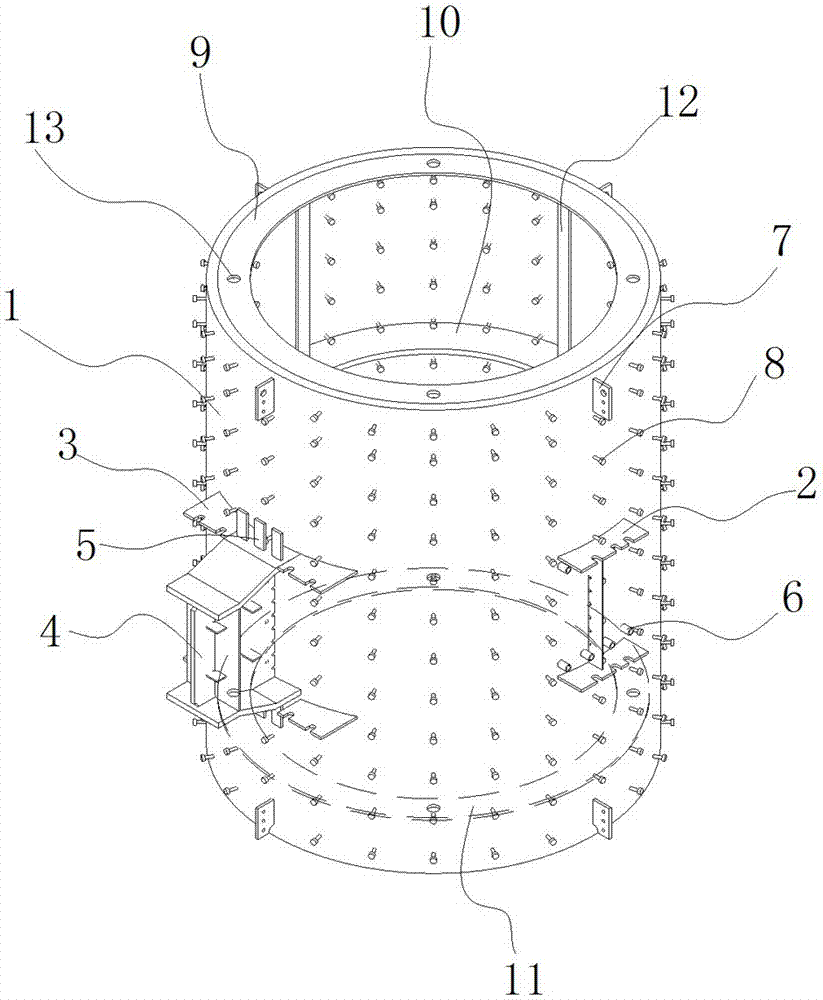

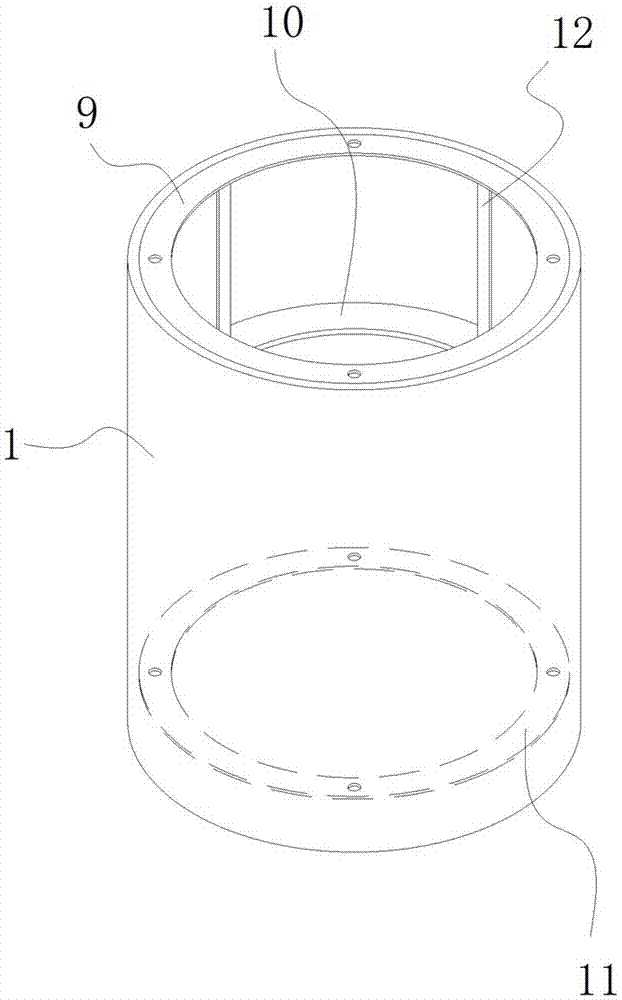

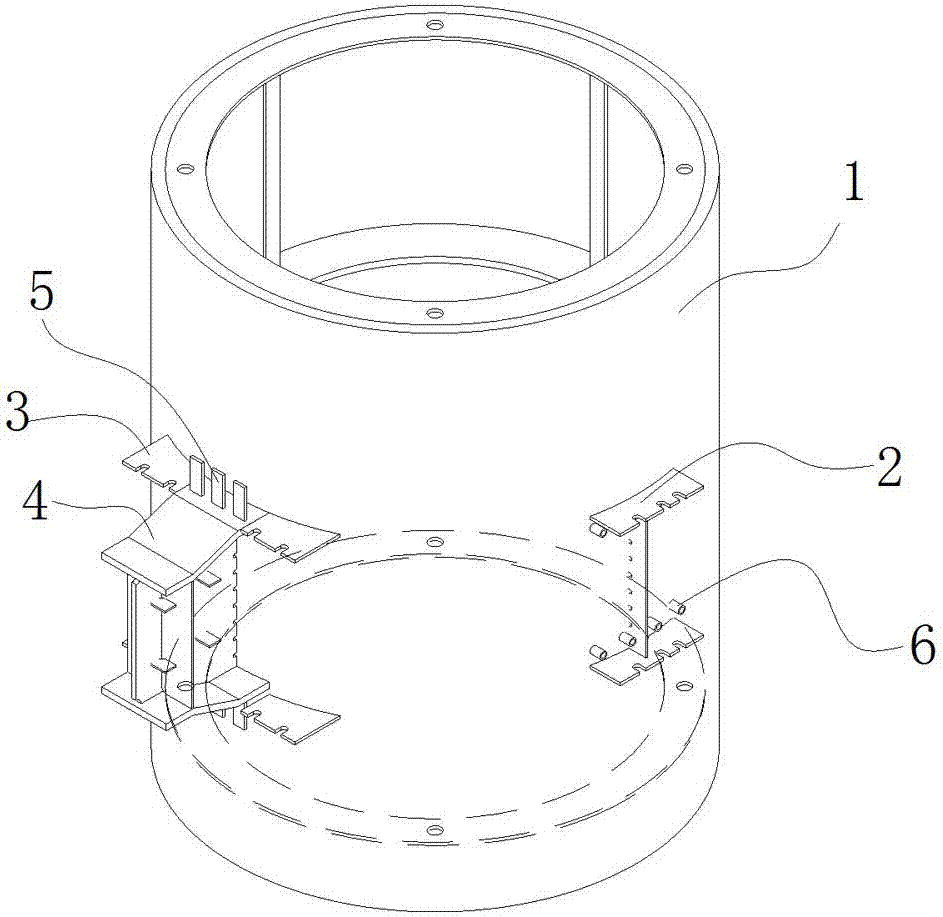

[0039] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, a large-diameter thick-walled steel pipe column includes a steel pipe 1. The outer wall of the steel pipe 1 is provided with a concrete beam assembly and a steel corbel 2. The concrete beam assembly includes a pair of concrete beams distributed at intervals between the upper and lower ends. Beam longitudinal reinforcement connecting plate 3, a pair of concrete beam longitudinal reinforcement connecting plates 3 are provided with a steel frame beam cantilever beam section 4 fixed to the steel pipe 1, and the upper part of the steel frame beam cantilever beam section 4 is provided with a number of spacers Distributed concrete beam longitudinal reinforcement connecting plate 5;

[0040] The upper end and the lower end of the steel corbel 2 are respectively provided with a concrete beam longitudinal reinforcement connecting sleeve 6;

[0041] The upper end and the lower end of the steel pipe 1 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com