Concrete shrinkage reducing agent and preparation method and application thereof

A technology of concrete shrinkage reducing agent and reactant, which is applied in the field of concrete shrinkage reducing agent and its preparation, can solve the problems that affect concrete strength, the mechanism of shrinkage reducing agent and shrinkage crack is not very clear, and achieve good freeze-thaw resistance and compressive strength. , Improve the physical properties of concrete, the effect of excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

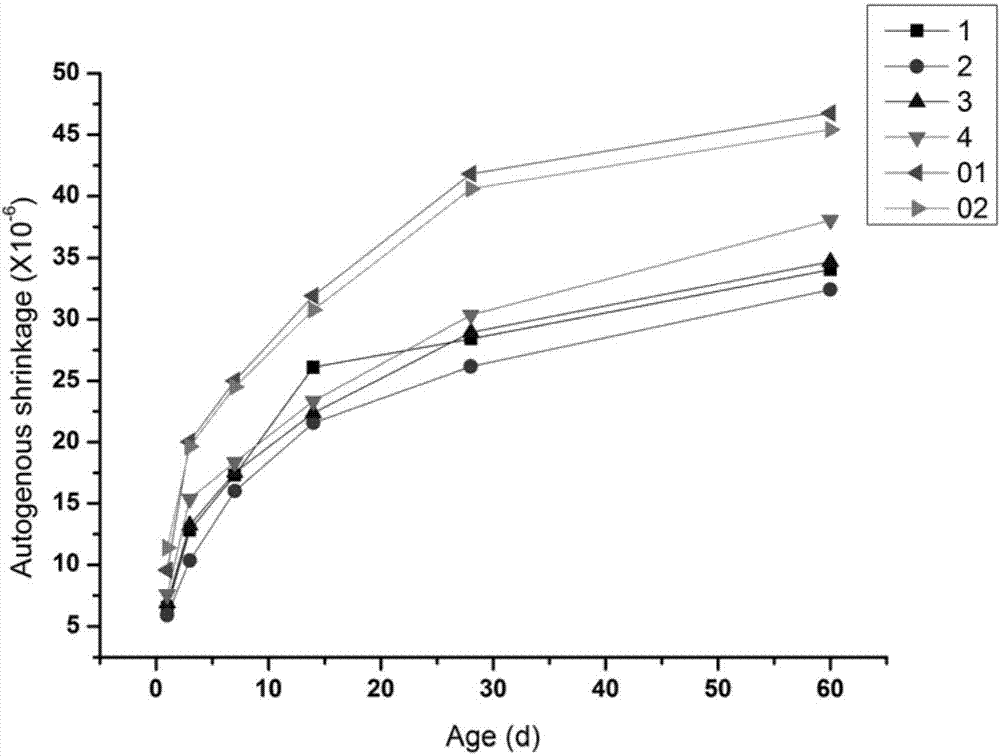

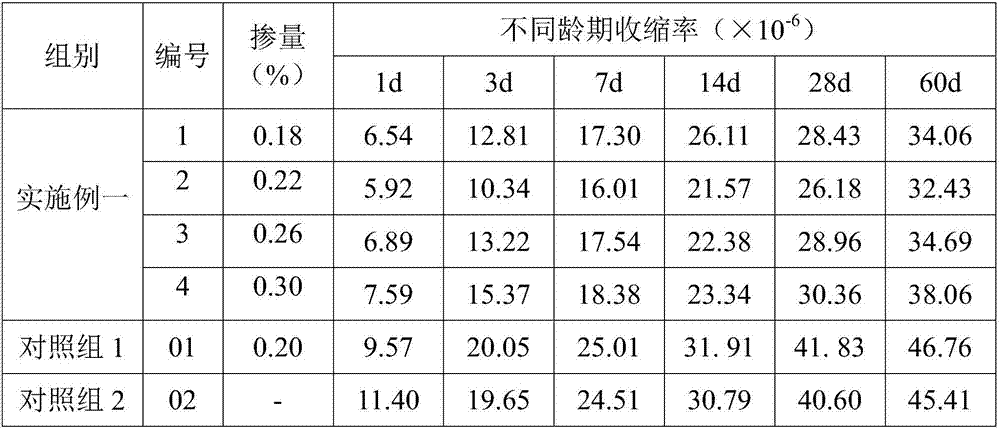

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of concrete shrinkage reducing agent, comprises the steps:

[0023] S101: Mix the first monomer, initiator and water uniformly to obtain the first reactant, and raise the temperature of the first reactant to 55-65°C; wherein, the first monomer is allyl with a weight average molecular weight of 1000-2400 base polyoxyethylene ether, the initiator is selected from one or more of azobisisobutyronitrile, dimethyl azobisisobutyrate, ammonium persulfate and potassium persulfate, and the initiator is the first monomer, 0.1%-2% of the total moles of the second monomer and the third monomer; the mass ratio of water to the first monomer is (0.5-1):1;

[0024]S102: uniformly mix the second monomer and water to obtain a second reactant; wherein, the second monomer is acrylic acid, and the mass ratio of water to the second monomer is (9-12):1;

[0025] S103: Mix the third monomer and the fourth monomer uniformly to obtain the third...

Embodiment 1

[0032] This embodiment provides a concrete shrinkage reducing agent and a preparation method thereof, the preparation method comprising the following steps:

[0033] S101: Mix 1 mol of the first monomer allyl polyoxyethylene ether (weight average molecular weight 1510), the initiator dimethyl azobisisobutyrate and water to obtain the first reactant, and raise the temperature of the first reactant to 60°C; wherein, the molar ratio of the first monomer, the second monomer, the third monomer and the fourth monomer is 1:2:1.5:0.2; the initiator is the first monomer, the second monomer and 1% of the total moles of the third monomer; the mass ratio of water and the first monomer is 0.8:1;

[0034] S102: uniformly mix the second monomer acrylic acid and water to obtain a second reactant; wherein the mass ratio of water to the second monomer is 10:1;

[0035] S103: uniformly mixing the third monomer diethylene glycol monobutyl ether methacrylate and the fourth monomer phellandrene to...

Embodiment 2

[0041] This embodiment provides a concrete shrinkage reducing agent and a preparation method thereof, the preparation method comprising the following steps:

[0042] S101: Mix 1 mol of the first monomer allyl polyoxyethylene ether (weight average molecular weight 1000), the initiator dimethyl azobisisobutyrate and water to obtain the first reactant, and raise the temperature of the first reactant to 55°C; wherein, the molar ratio of the first monomer, the second monomer, the third monomer and the fourth monomer is 1:0.8:0.8:0.1; the initiator is the first monomer, the second monomer and 0.1% of the total moles of the third monomer; the mass ratio of water and the first monomer is 0.5:1;

[0043] S102: uniformly mix the second monomer acrylic acid and water to obtain a second reactant; wherein, the mass ratio of water to the second monomer is 9:1;

[0044] S103: uniformly mixing the third monomer diethylene glycol monobutyl ether methacrylate and the fourth monomer phellandren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com