Synthesis and post-treatment method of high-purity N-carbamylglutamic acid

A technology of carbamoyl glutamic acid and sodium glutamate, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of sulfate/bisulfate, etc., can solve the problems of high cost, complex process, low product purity, etc. problems, to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The steps of the synthesis of the high-purity N-carbamylglutamic acid and its post-processing method of the present invention are as follows:

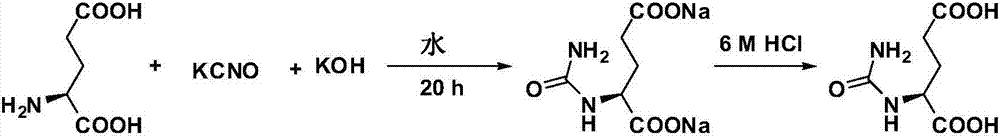

[0026] a, the 1:1 molar ratio of sodium glutamate and sodium cyanate is added to the reaction kettle, and water is used as a solvent, and the reaction is stirred at 50 °C;

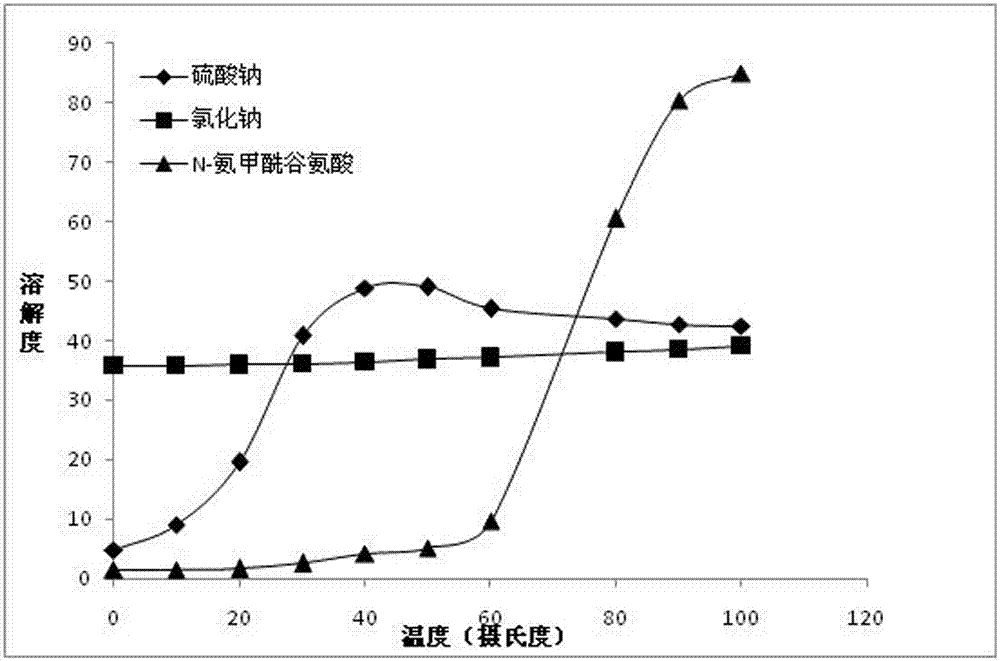

[0027] b, the reaction solution was cooled, acidified to PH=3 with 80% sulfuric acid by mass, then heated to 40° C., stirred uniformly, and filtered to obtain the target product; the product purity was 99.2%.

[0028] c, the mother liquor is cooled to 0°C, the hydrated sodium sulfate is precipitated, and filtered to obtain the by-product hydrated sodium sulfate, and the filtrate is adjusted to neutrality with sodium hydroxide solution for recycling.

Embodiment 2

[0030] The steps of the synthesis of the high-purity N-carbamylglutamic acid and its post-processing method of the present invention are as follows:

[0031] a, the 1:1 molar ratio of sodium glutamate and sodium cyanate is added to the reactor, and water is used as a solvent, and the reaction is stirred at 30 °C;

[0032] b, the reaction solution is cooled, acidified to PH=3 with 90% sulfuric acid by mass, then heated to 50° C., stirred evenly, and filtered to obtain the target product; the product has a purity of 99.5%.

[0033] c, the mother liquor is cooled to 5°C, the hydrated sodium sulfate is precipitated, and filtered to obtain the by-product hydrated sodium sulfate, and the filtrate is adjusted to neutrality with sodium hydroxide solution for recycling.

Embodiment 3

[0035] Get embodiment 1 filtrate, liquid chromatography detects the glutamic acid content in the solution, adds sodium hydroxide solution and adjusts the pH value to be 7, adds corresponding sodium glutamate and sodium cyanate, distilled water according to the condition of embodiment 1, stirs down The reaction was heated to 50° C., processed according to the treatment steps of Example 1, and the filtrate was repeated 3 times. The results were as follows, and the purity was all greater than 99.2%.

[0036] repeat times one two three purity(%) 99.5 99.2 99.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com