Plastic pelletizing residue cleaning device

A cleaning device and granulation technology, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of material accumulation at the discharge port, failure of normal discharge at the discharge port, and impact on production efficiency, so as to facilitate recycling and processing , Conducive to performance maintenance and reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

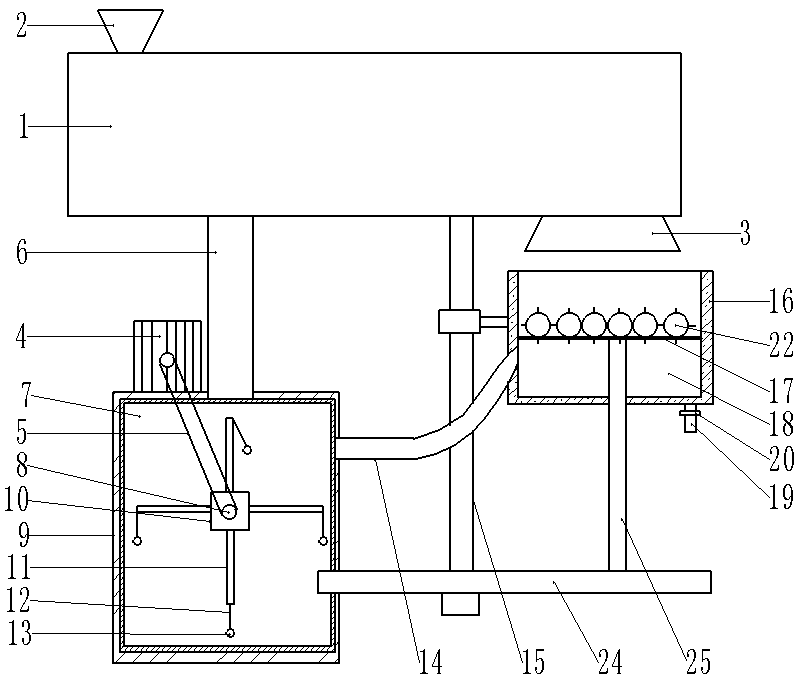

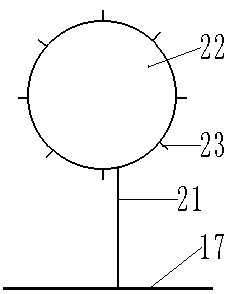

[0018] The reference signs in the accompanying drawings of the description include: pelletizing cylinder 1, feed inlet 2, discharge outlet 3, motor 4, belt 5, suction pipe 6, bellows 7, horizontal shaft 8, glass wool board 9, fan 10 , fan blade 11, steel wire 12, hanging ball 13, blowing pipe 14, boom 15, cleaning tank 16, leaking screen 17, storage cavity 18, discharge pipe 19, switch 20, elastic rope 21, cleaning ball 22, Acupuncture part 23, leaf spring 24, push rod 25.

[0019] The embodiment is basically as figure 1 Shown: Plastic granulation residue cleaning device, including granulation cylinder 1 and motor 4, the left part of granulation cylinder 1 is provided with an upward feeding port 2, and the right part of granulation cylinder 1 is provided with a downward discharge port 3. The lower end of pelletizing cylinder 1 is welded with suction pipe 6, and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com