Roller crusher

A technology of roller crusher and feeding hopper, which is applied in the direction of grain processing, etc., and can solve unsolved problems such as wet material feeding and wall hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

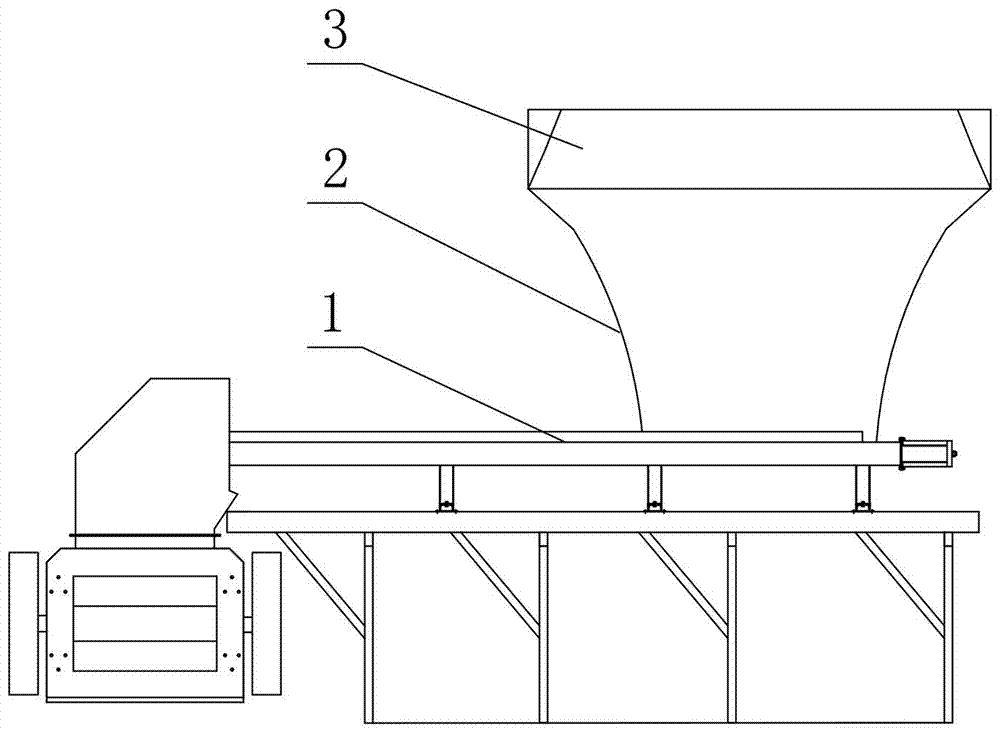

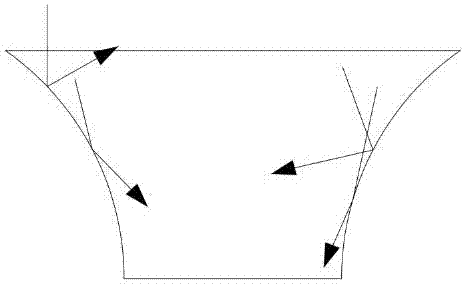

[0022] Such as figure 1 , figure 2 and image 3 As shown, a roll crusher 1 includes a feed hopper 2, the feed hopper 2 is composed of at least three side plates, one of the side plates corresponding to the feed side of the feed hopper 2, Two or more pieces are arc-shaped plates, and the arc-shaped plates are arc-shaped structures that expand outward from bottom to top. When the wet ore falls onto the arc-shaped plate, it is not easy to stick to the arc-shaped plate because the contact mode with the arc-shaped plate is point contact.

[0023] In a specific application, for the convenience of processing and manufacturing, the feed hopper 2 is usually composed of four side plates. In order to reduce the adhesion of wet materials on the feed hopper 2, the corresponding feeding hopper The pair of side plates are the arc-shaped plates. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com