Vibration signal combined denoising method

A vibration signal and signal technology, which is applied in the field of joint noise reduction of vibration signals based on wavelet transform modulus maximum value and independent component analysis, can solve the problem of poor separation effect, monitoring of equipment operating status, fault diagnosis interference, and inability to solve single-channel noise. ICA underdetermined problem and other problems, to achieve the effect of obvious features, poor separation effect, and beneficial fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

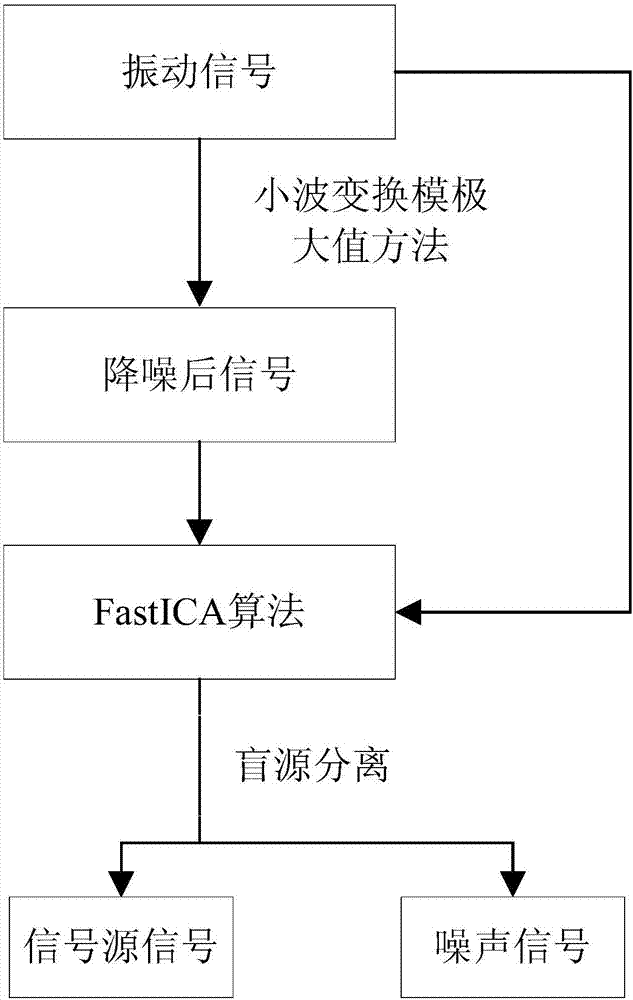

[0016] Such as figure 1 As shown, the present invention provides a method for joint noise reduction of vibration signals based on wavelet transform modulus maximum and independent component analysis, the method comprising the following steps:

[0017] 1) Perform wavelet transform modulus maxima decomposition on the collected vibration signal x(t), reconstruct the signal to obtain the noise-reduced signal, where t represents time;

[0018] The specific process is as follows:

[0019] 1.1) Perform wavelet decomposition on the vibration signal x(t).

[0020] According to the characteristics of the vibration signal, the number of decomposition scales is preferably 5, and the number of decomposition scales is selected as a db3 wavelet base with good compact support, orthogonality and relatively high vanishing moment.

[0021] 1.2) Calculate the modulus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com