Composite pasting membrane, manufacturing method, unsymmetrical perspective glass and transparent rear projection screen

A composite paste and glass plate technology, which is applied in optics, instruments, projection devices, etc., can solve the problem that the glass cannot meet the demand, and achieve the effects of simplifying the assembly process and process times, improving assembly efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

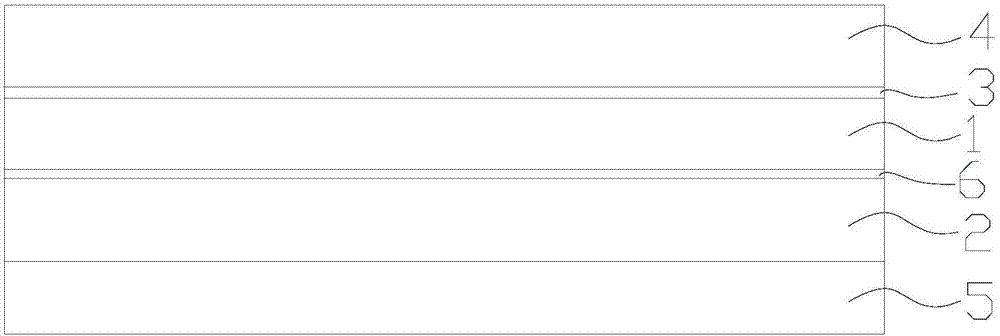

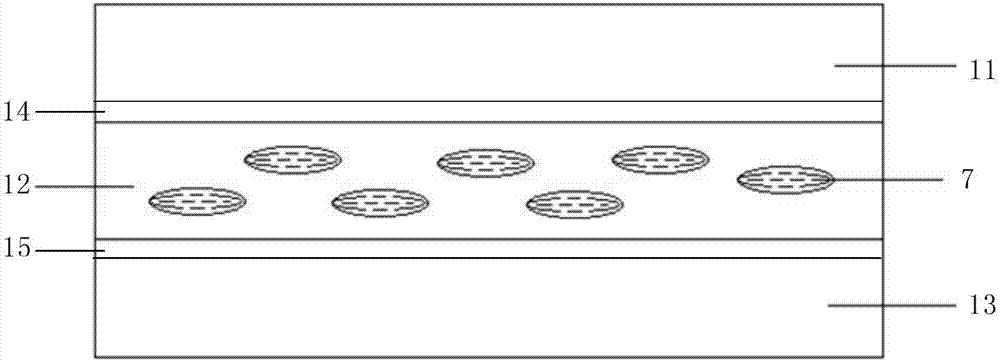

[0033] Such as Figure 1 to Figure 2 As shown, the embodiment of the present invention proposes a composite film, including a scattering polarizing layer 1 and an absorbing polarizing layer 2 bonded to the scattering polarizing layer 1. The scattering polarizing layer 1 includes a first triacetate film layer 11, The polyvinyl alcohol doped liquid crystal film layer 12 and the second cellulose triacetate film layer 13 .

[0034] The composite film provided by the above technical solution, when the light is incident, because the scattering polarizing layer 1 has a light transmission axis, half of the light is transmitted and half of the light is scattered; The composite film formed by compounding the scattering polarizing layer 1 has an asymmetrical visual effect. Viewed from the side of the scattering polarizing layer 1, it is a colorless translucent co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com