Multichannel intelligent cation exchange system

A cation exchange and intelligent technology, applied in the field of cation exchange system, can solve the problems of measurement result deviation, large space occupation, positive error, etc., and achieve the effect of stable performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

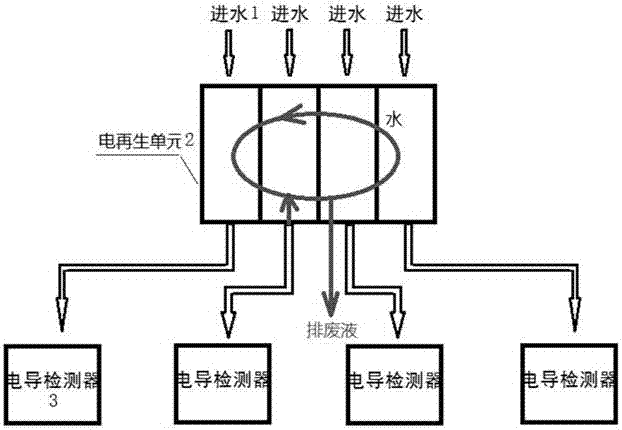

[0010] see figure 1 , the present invention includes four parallel electrical regeneration units 2 with water inlet 1 and strong acidic cation exchange resin, and each electrical regeneration unit 2 is applied with a working current of 5-1000mA to generate H through electrolysis of water + , the outlet water of each electrical regeneration unit 2 is respectively connected with its own conductance detector 3, and the water containing H after passing through the conductance detector 3 + The water sample is returned to each electric regeneration unit 2 to regenerate the strongly acidic cation exchange resin in the electric regeneration unit 2 .

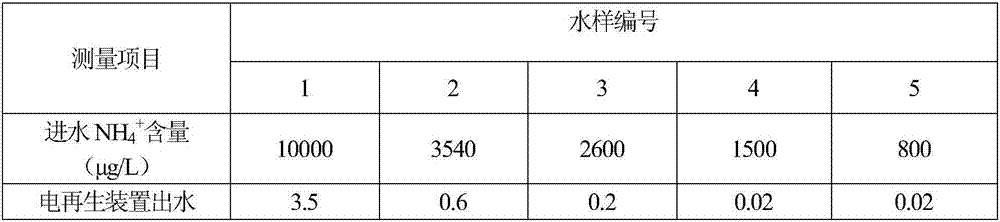

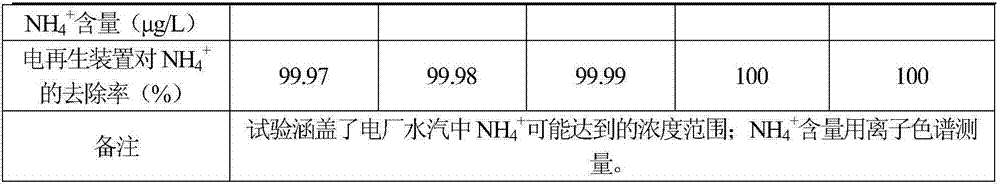

[0011] There is a single intelligent ion exchange unit: the electric regeneration device is filled with cation exchange resin, and the water sample enters the electric regeneration ion exchange device to remove cations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com