Device suitable for intermittent mixing and adding of liquid additive and method

A liquid additive, intermittent technology, applied in the direction of mixing operation control device, liquid ingredient supply device, clay preparation device, etc., can solve the problems of incomplete automatic addition, liquid additive residue, and the impact of the next addition, so as to shorten the addition Time, not easy to residue, avoid the effect of pipeline residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

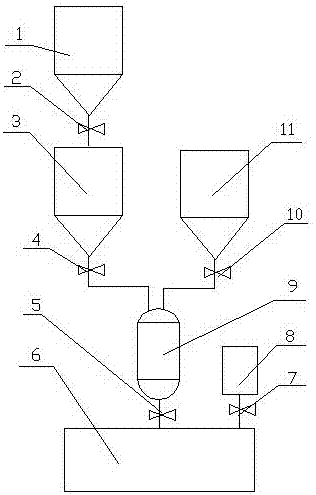

[0025] As shown in the drawings: a device suitable for batch mixing and adding liquid additives, including liquid storage tank 3, compressed air tank 11, weighing air pressure adding tank 9, weighing mixer 6 and material silo 8, liquid storage Barrel 3 and compressed air tank 11 are communicated with weighing air pressure adding tank 9 through pipeline respectively, and weighing air pressure adding tank 9 is communicated with weighing mixer 6 through pipeline, and material silo 8 is also communicated with weighing mixer 6 through pipeline; The pipeline between the liquid storage tank 3 and the weighing air pressure adding tank 9 is provided with a first electromagnetic valve 4, and the pipeline between the compressed air tank 11 and the weighing air pressure adding tank 9 is provided with a second electromagnetic valve 10, and the weighing A third solenoid valve 5 is provided on the pipeline between the air pressure adding tank 9 and the weighing mixer 6 , and a fourth solenoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com