Automatic turnover type solid-liquid separation settling tank

A technology of solid-liquid separation and automatic flipping, which is applied to control the inclination of sedimentation equipment and the direction of settling tanks, etc. It can solve the problems of wasting time, low mud pumping efficiency of mud discharge pipes, and residual sediment, etc., and achieves strong maneuverability, High structural stability and effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

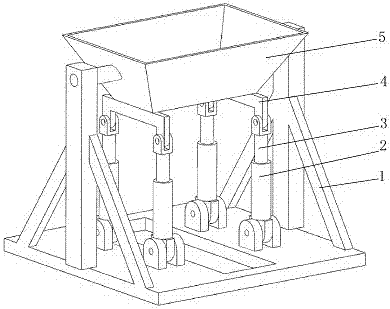

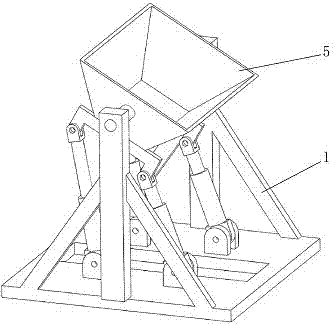

[0013] Such as Figure 1-2 As shown, the present invention mainly includes a sedimentation tank 5 for containing the mixed solution, the sedimentation tank 5 is installed on the chassis support 1 through a hinged connection, the bottom of the sedimentation tank 5 is fixedly installed with a mounting seat 4, and four first hydraulic cylinders 2 They are divided into two pairs and installed on the chassis bracket 1 through a hinged connection, and the first hydraulic rod 3 on the first hydraulic cylinder 2 cooperates with the mounting seat 4 through a hinged connection.

[0014] When working, install the device under the ground so that the bottom of the sedimentation tank 5 coincides with the ground, the chassis support 1 is fixed to the ground through bolts, the first hydraulic cylinder 2 is connected to the hydraulic control system, and the external device inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com