An electric-heating equipment omnidirectional heat radiation apparatus

A technology of heat dissipation device and electric heating equipment, which is applied in the structural parts of electrical equipment, electrical components, cooling/ventilation/heating transformation, etc., and can solve problems such as failure of electric heating equipment, safety accidents, and lack of heat dissipation function of electric heating equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

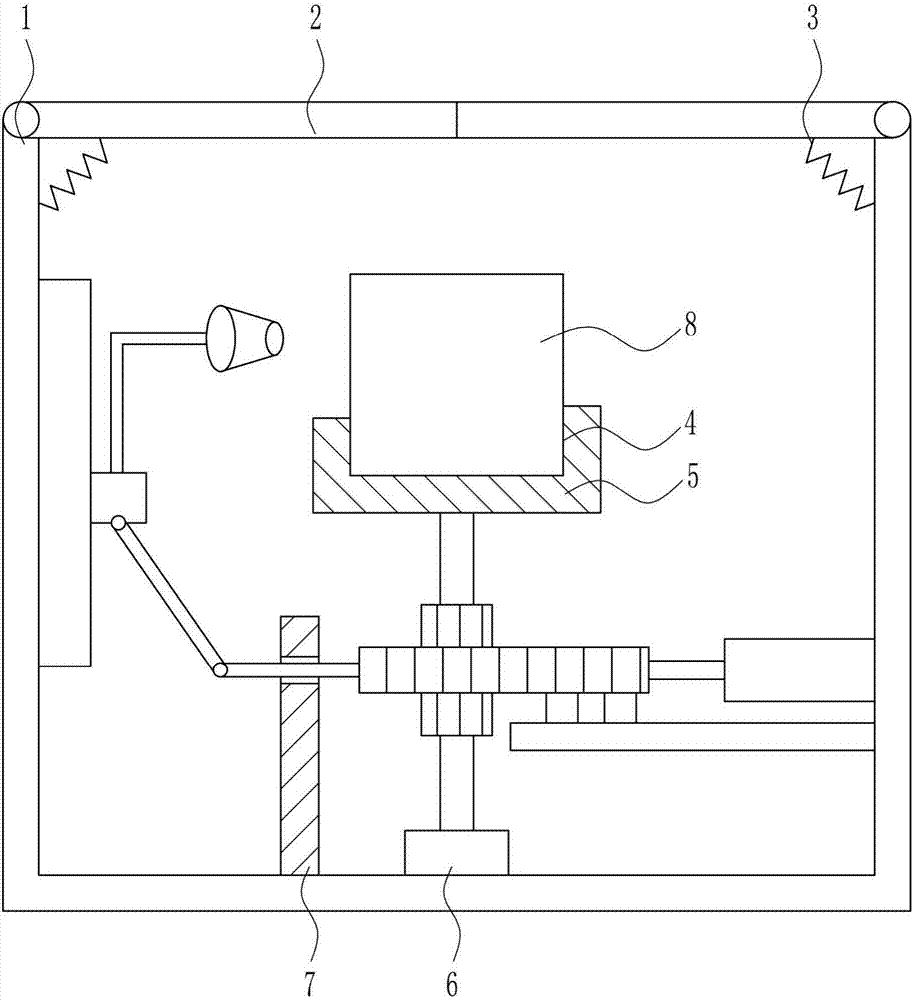

[0032] An all-round cooling device for electric heating equipment, such as Figure 1-5 As shown, it includes a processing box 1, a baffle plate 2, a first elastic member 3, a placement plate 5, a rotating device 6 and a blowing device 7; A first elastic member 3 is connected between the bottom of the plate 2 and the inner wall of the processing box 1, the bottom of the processing box 1 is provided with a rotating device 6 and a blowing device 7, the rotating device 6 is located on the right side of the blowing device 7, and the rotating device 6 top is provided with The placement board 5 is provided with a placement slot 4 on the top of the placement board 5 .

Embodiment 2

[0034] An all-round cooling device for electric heating equipment, such as Figure 1-5 As shown, it includes a processing box 1, a baffle plate 2, a first elastic member 3, a placement plate 5, a rotating device 6 and a blowing device 7; A first elastic member 3 is connected between the bottom of the plate 2 and the inner wall of the processing box 1, the bottom of the processing box 1 is provided with a rotating device 6 and a blowing device 7, the rotating device 6 is located on the right side of the blowing device 7, and the rotating device 6 top is provided with The placement board 5 is provided with a placement slot 4 on the top of the placement board 5 .

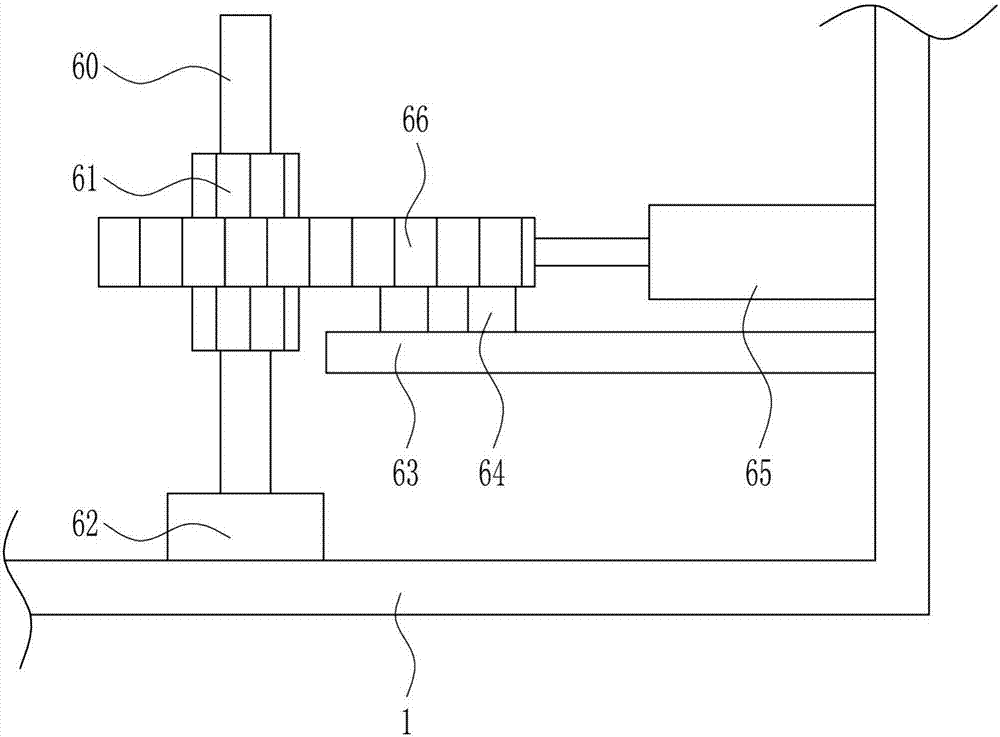

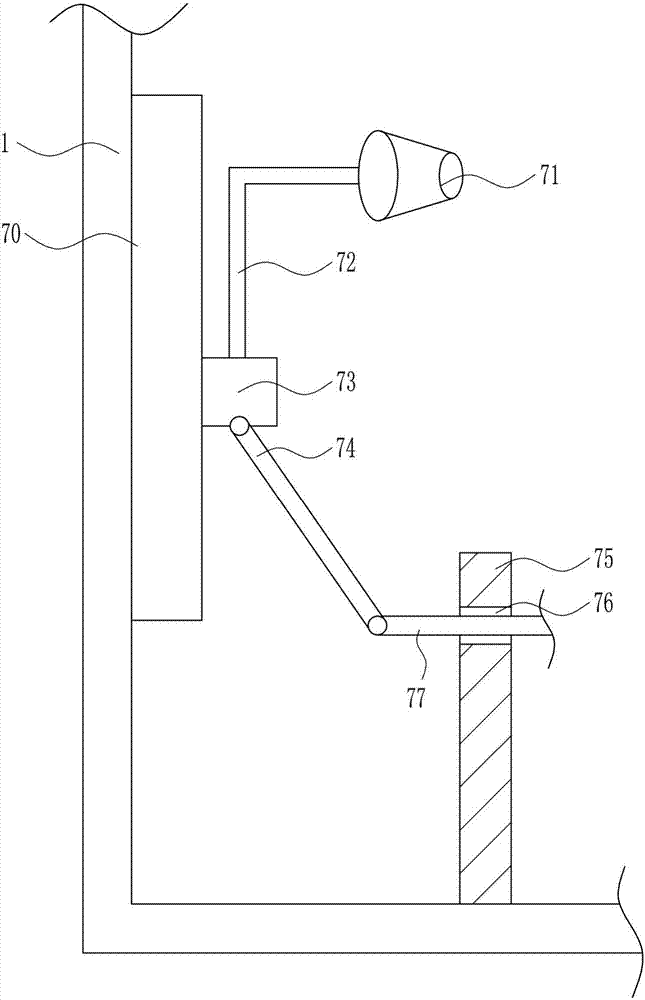

[0035]The rotating device 6 includes a rotating shaft 60, a gear 61, a bearing seat 62, a first slide rail 63, a first slide block 64, an electric push rod 65 and a rack 66, and the inner bottom of the processing box 1 is provided with a bearing seat 62, and the bearing seat 62 A rotating shaft 60 is installed on the ...

Embodiment 3

[0037] An all-round cooling device for electric heating equipment, such as Figure 1-5 As shown, it includes a processing box 1, a baffle plate 2, a first elastic member 3, a placement plate 5, a rotating device 6 and a blowing device 7; A first elastic member 3 is connected between the bottom of the plate 2 and the inner wall of the processing box 1, the bottom of the processing box 1 is provided with a rotating device 6 and a blowing device 7, the rotating device 6 is located on the right side of the blowing device 7, and the rotating device 6 top is provided with The placement board 5 is provided with a placement slot 4 on the top of the placement board 5 .

[0038] The rotating device 6 includes a rotating shaft 60, a gear 61, a bearing seat 62, a first slide rail 63, a first slide block 64, an electric push rod 65 and a rack 66, and the inner bottom of the processing box 1 is provided with a bearing seat 62, and the bearing seat 62 A rotating shaft 60 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com