A multi-processor permanent magnet brushless direct current motor combined speed regulation system

A permanent magnet brushless DC and brush DC motor technology, which is applied in the direction of single motor speed/torque control, control system, motor control, etc., can solve the problem of increasing the size and cost of brushless DC motors, and the inability of the motor to run continuously and stably. Reduce the continuity of motor operation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0034] The invention has the advantages of diversified motor rotor position data detection functions, multi-processor joint operation and double drive bridge drive, and is suitable for the technical field of high-precision brushless DC motor speed regulation.

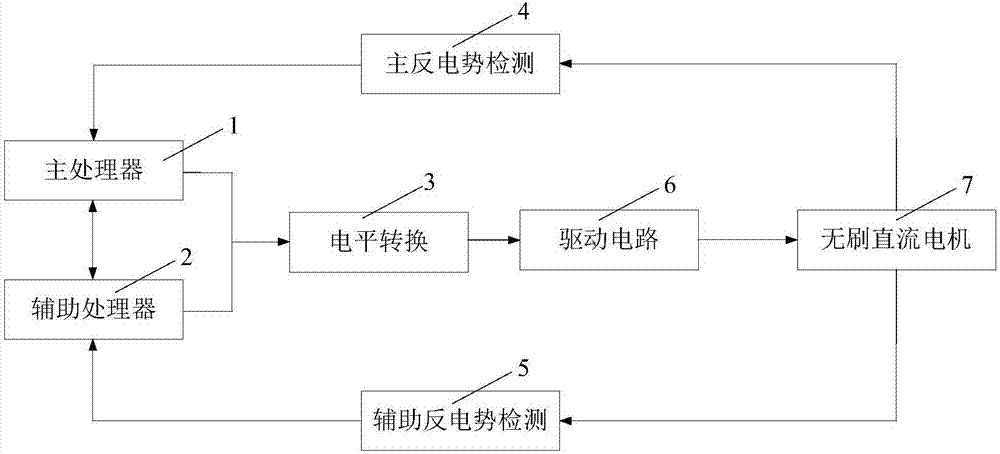

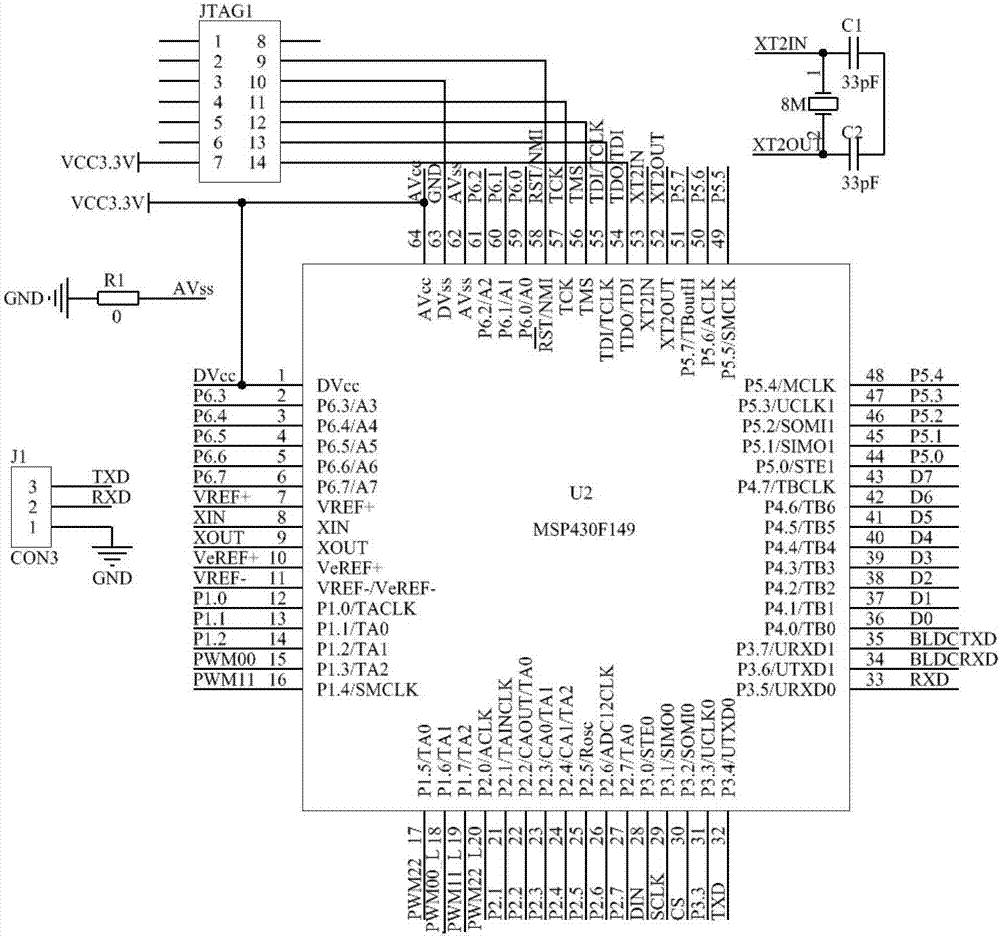

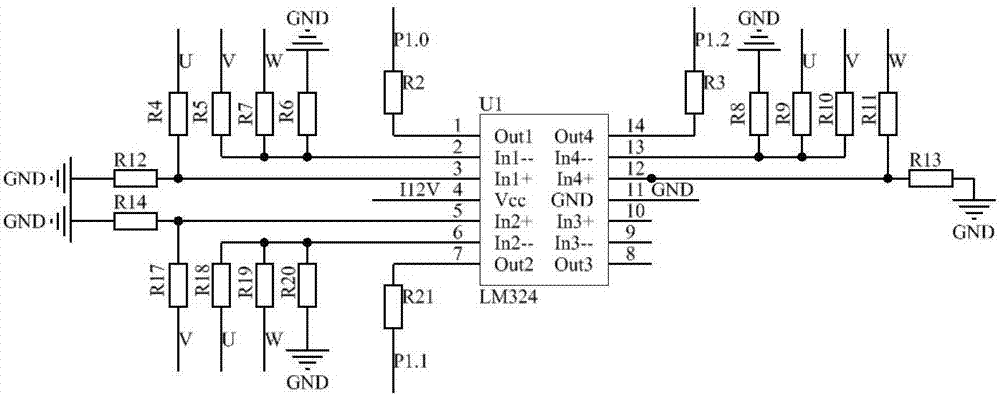

[0035] Such as figure 1 As shown, the present invention includes a brushless DC motor 7, a main processor module 1, an auxiliary processor module 2, a level conversion module 3, a main back EMF detection module 4, an auxiliary back EMF detection module 5 and a drive circuit module 6; wherein ,

[0036] Both the main processor module 1 and the auxiliary processor module 2 are used to collect the rotor position of the brushless DC motor 8, and respectively output digital PWM signals for controlling the rotational speed of the brushless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com