Liquid crystal photonic crystal fiber random laser and manufacturing method therefor

A technology of photonic crystal fiber and random laser, which is applied in the field of optical lasers, can solve the problems of weak light intensity and uncertain direction of random laser emission, and achieve the effect of increasing laser intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

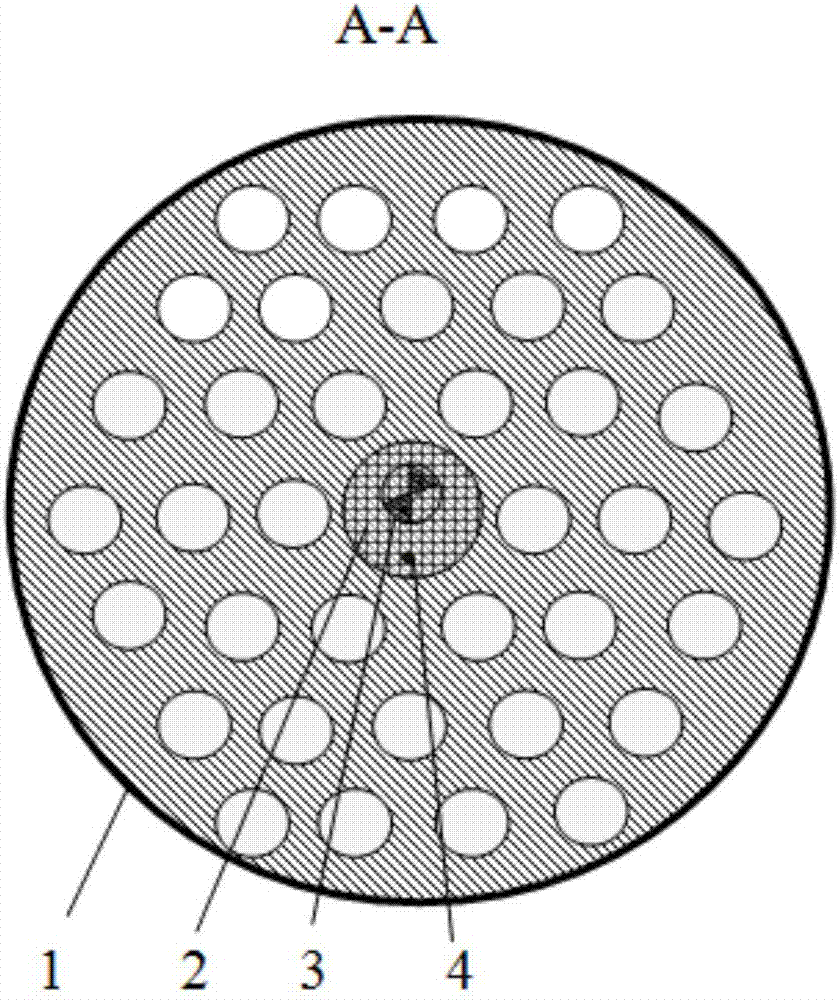

[0029] Liquid crystal photonic crystal fiber random laser, including hollow photonic crystal fiber 1, dye-doped cholesteric liquid crystal microspheres and polyvinyl alcohol aqueous solution 2, the dye-doped cholesteric liquid crystal microspheres are composed of large-sized doped Dye cholesteric liquid crystal microspheres 3 and small-sized dye-doped cholesteric liquid crystal microspheres 4; inject the dye-doped cholesteric liquid crystal microspheres and the aqueous solution 2 of polyvinyl alcohol into the hollow photonic crystal fiber 1 after stirring In the middle of the core.

[0030] The core size of the hollow photonic crystal fiber 1 is 50-200 microns, and five to seven layers of air holes are arranged in a triangular shape around the core.

[0031] The cholesteric liquid crystal microspheres doped with dyes are cholesteric liquid crystal microspheres doped with laser dyes.

[0032] The diameter of the dye-doped cholesteric liquid crystal microspheres is 0.5-10 micro...

Embodiment 2

[0043] After the aqueous solution of dye-doped cholesteric liquid crystal and polyvinyl alcohol is stirred, the liquid crystal droplets are suspended in the aqueous solution of polyvinyl alcohol in the form of microspheres of different sizes, and the larger-sized droplets in the microspheres have a good helical structure , while small-sized droplets have no regular helical structure due to the length of the pitch. Such larger liquid crystal micro-droplets play the role of gain, and small micro-droplets play the role of dispersion, and the aqueous solution of polyvinyl alcohol can make the liquid crystal micro-droplets exist in the form of intact spheres. Due to the scattering effect of small droplets, the direction of random emission is uncontrollable. The microstructure of the photonic crystal fiber reflects the emitted light, thereby controlling the transmission direction of the emitted light along the fiber, and thus improving the emission efficiency of the laser.

[0044]...

Embodiment 3

[0051] Same as embodiment 2, its difference mainly lies in:

[0052] The fiber core is selected as a hollow photonic crystal fiber with a core diameter of 50-200 microns, and five to seven layers of air holes are arranged in a triangular shape around the core;

[0053] The chiral agent is used to configure the cholesteric liquid crystal, and the mass percentage concentration of the chiral agent is adjusted to obtain a photonic band gap position consistent with the forbidden band position of the photonic crystal fiber itself. Select the laser dye whose fluorescence spectrum is in the forbidden band interval, dope it into the prepared cholesteric liquid crystal, and use ultrasonic oscillation equipment to carry out sufficient and uniform mixing;

[0054] Prepare an aqueous solution with a mass percentage of polyvinyl alcohol of 5%-15%, mix and stir with the dye-doped cholesteric liquid crystal, and the volume of the two is between 1:1 and 1:2. Liquid crystal microspheres of var...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com