Novel device for detecting inner rolling path profile of ball screw nut, and method of device

A ball screw nut and inner raceway technology, applied in the field of measurement, can solve the problems of large human factors, low efficiency, large errors, etc., and achieve the effects of good stability, high efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

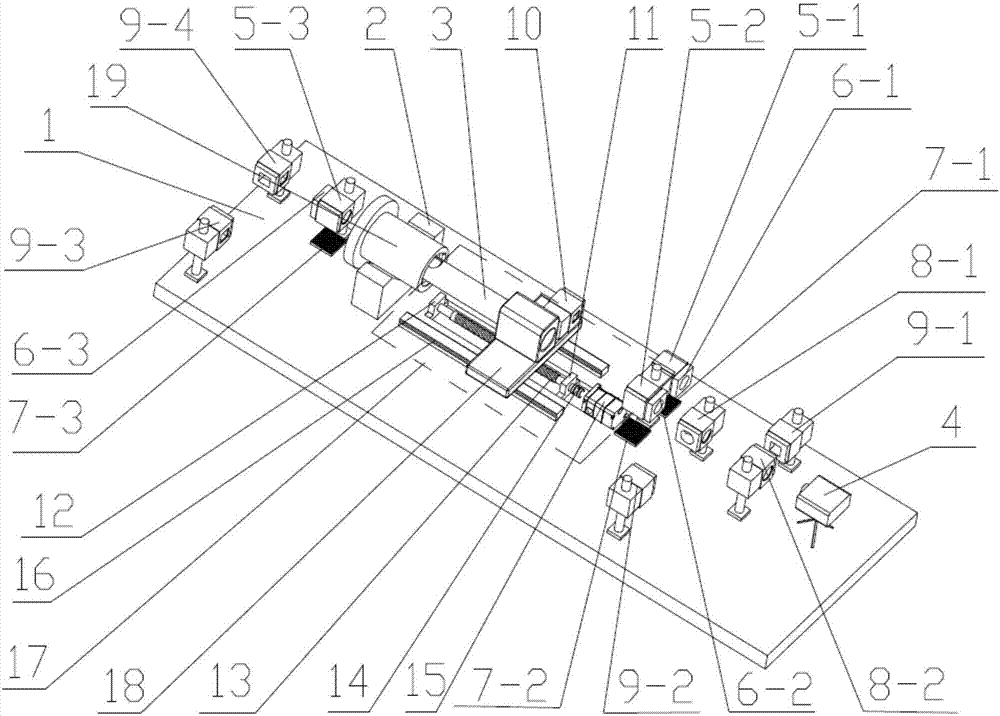

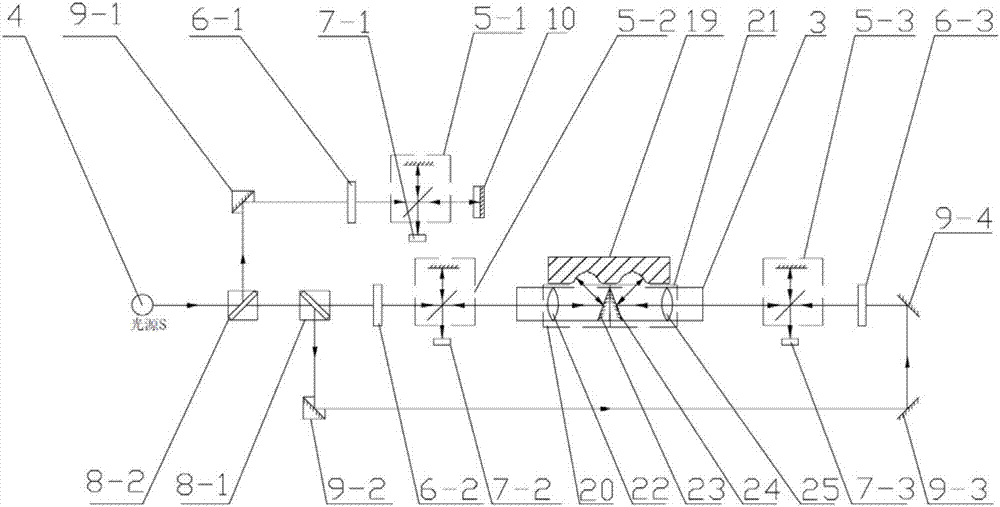

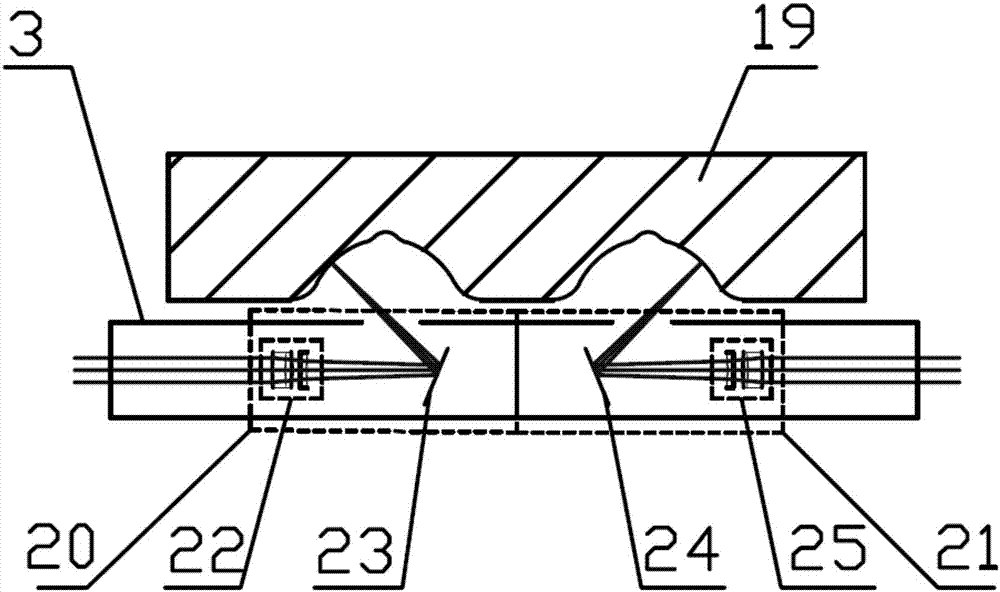

[0046] combine figure 1 , figure 2 , image 3 , a new ball screw nut inner raceway profile detection device of the present invention, including a marble platform and a nut clamping device arranged on the marble platform, an X-axis linear motion platform, a dual-frequency laser generator, a first laser interference instrument, the first collimating mirror and the first photodetector, the second laser interferometer supporting the first laser interferometer, the second collimating mirror and the second photodetector supporting the second laser interferometer, the third Laser interferometer, the third collimating mirror and the third photodetector matched with the third laser interferometer, the first light beam splitter, the second light beam splitter, the first light right-angle reflector, the second light right-angle reflector mirror, the third ray right-angle reflector and the fourth ray right-angle reflector;

[0047] The X-axis linear motion platform is located between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com