Active control device of supersonic blunt trailing edge mixed layer

An active control, supersonic technology, applied in the field of supersonic speed, it can solve problems such as control failure and melting of the vibration plate, and achieve the effect of avoiding easy melting and simple mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The accompanying drawings constituting a part of this application are used to provide further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

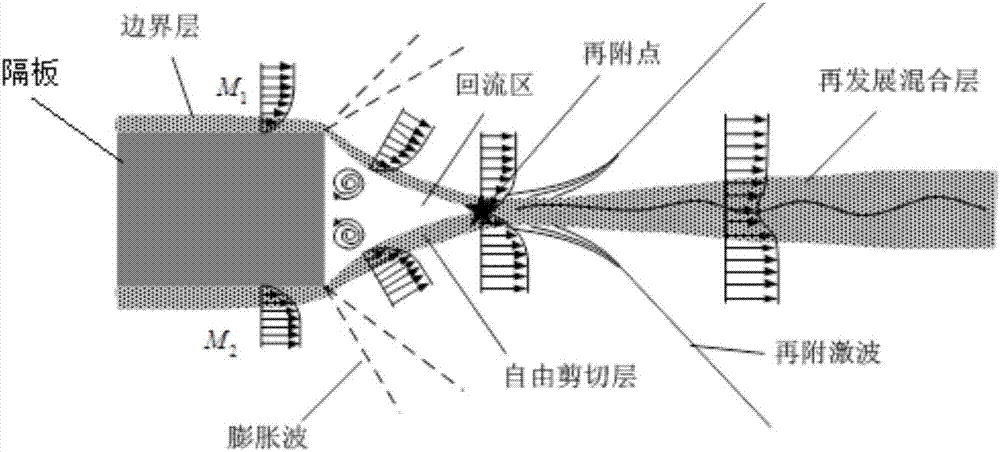

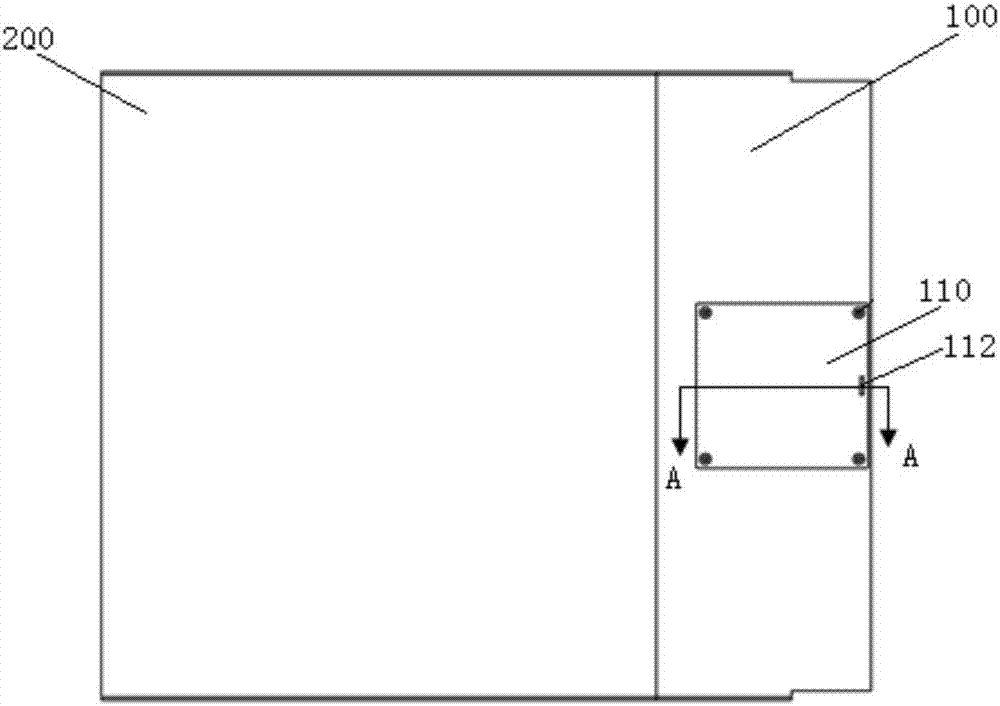

[0032] see Figure 2~4 , the active control device for the supersonic obtuse trailing edge mixed layer provided by the present invention is arranged on the trailing edge of the partition away from the end of the supersonic incoming flow 300 .

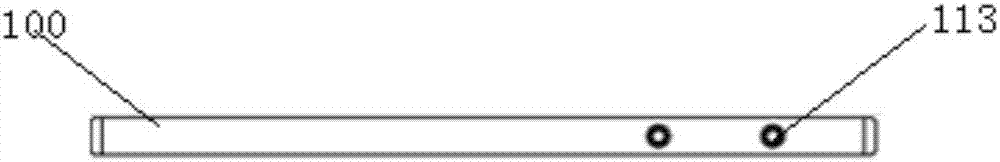

[0033] The separator may be a first separator part 100 and a second separator part 110 connected to each other at one end. The splicing here can be plug splicing or glue splicing. In one embodiment, the first partition 100 and the second partition 110 are connected by fixing screws 113 , and the fixing screws 113 pass through the first partition 100 and then connect with the second partition 110 .

[0034] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com