Construction method for preventing surrounding subsidence and local damage of urban road manhole

A construction method and inspection well technology, which can be applied to roads, roads, artificial islands, etc., can solve the problems of uneven settlement of roadbed compaction around inspection wells, weak connections, and difficult control of bending and tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

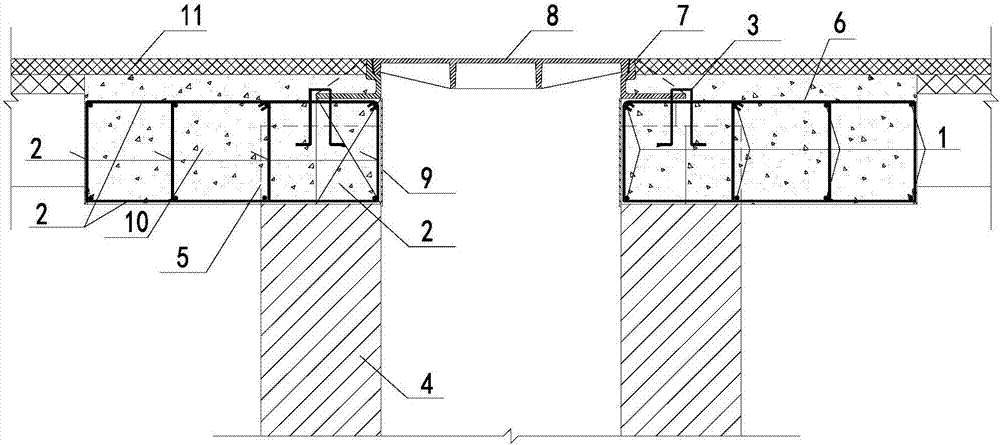

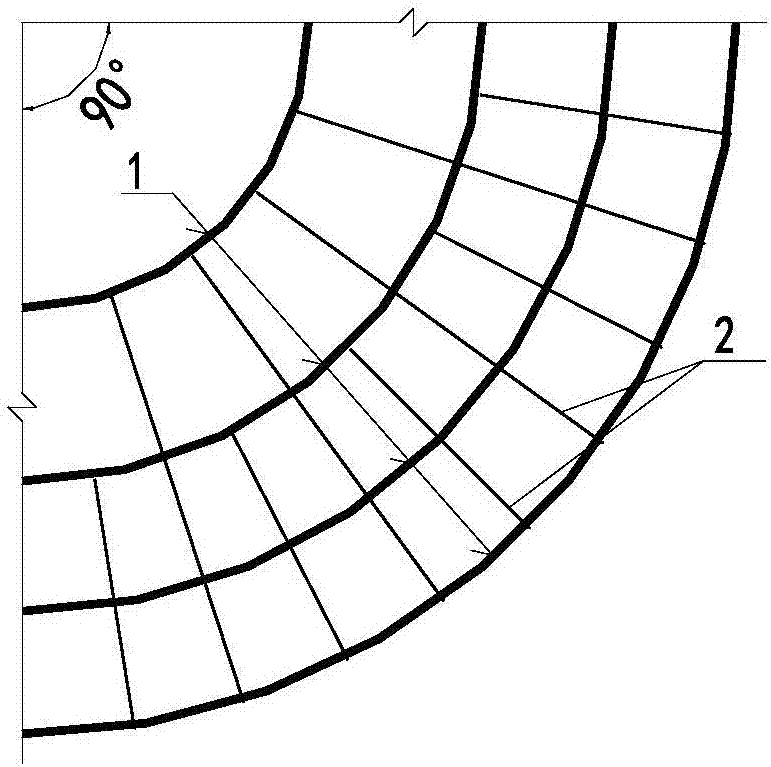

[0083] 1. Scope of treatment around the well

[0084] According to the picture and the scope of the subsidence around the inspection well, the treatment range around the well is drawn up. According to many years of experience, the treatment area around the well is usually 350mm outside the wall of the inspection well, and the old pavement structure within the range shall be removed. When checking the treatment area around the wellbore and it is not guaranteed to remove the damaged parts, the treatment area around the well should be increased according to the situation.

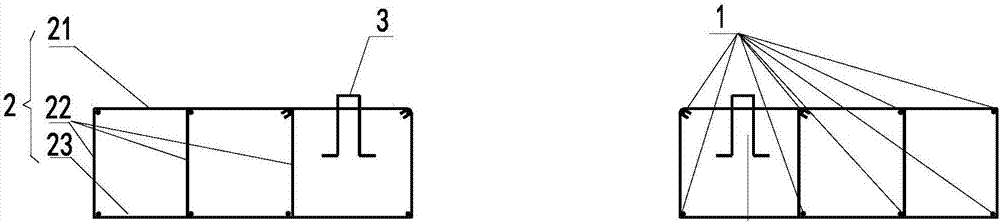

[0085] 2. Processing and installation of reinforcement cage around the well

[0086] 1) The diameter, type, spacing and geometric dimensions of the reinforcement cage around the well shall meet the requirements of the design and the actual situation on the site, and the joints of the main reinforcement bars under circumferential stress must be welded firmly, without deformation and corrosion.

[0087] 2) The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com