Mosquito-repellent nylon 6 fiber and preparation method thereof

A technology for repelling mosquitoes and nylon, which is applied in the field of mosquito repelling nylon 6 fiber and its preparation, which can solve problems such as environmental protection and safety issues, and achieve good effect of avoiding and repelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

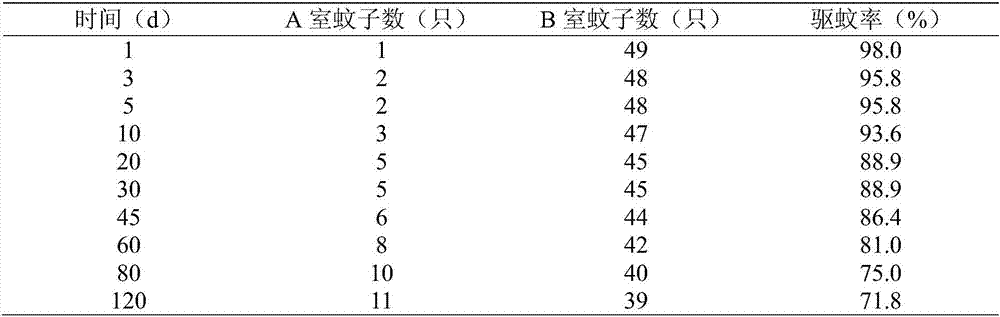

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 citronella extract

[0031] Crush the citronella grass, put it in the extraction kettle, use 70-90% ethanol as the entrainer, and adjust the supercritical CO 2 Fluid temperature and pressure; the extraction temperature is 50°C, the extraction pressure is 15MPa, and the extraction time is 1.5h; the extract is collected, concentrated by centrifugation and evaporated to dryness.

Embodiment 2

[0032] The preparation of embodiment 2 Peppermint extract

[0033] Crush the mint, put it in the extraction kettle, use 70-90% ethanol as the entrainer, and adjust the supercritical CO 2 Fluid temperature and pressure; the extraction temperature is 50°C, the extraction pressure is 15MPa, and the extraction time is 2h; the extract is collected, concentrated by centrifugation and evaporated to dryness.

Embodiment 3

[0034] The preparation of embodiment 3 Artemisia argyi extract

[0035] Crush Artemisia argyi leaves, place them in an extraction kettle, use 70-90% ethanol as entrainer, and adjust supercritical CO 2 Fluid temperature and pressure; the extraction temperature is 40°C, the extraction pressure is 15MPa, and the extraction time is 2h; the extract is collected, concentrated by centrifugation and evaporated to dryness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com