Neopentane beta-cyclodextrin hydroxypropyl tetraether and preparation method and application thereof

A technology of hydroxypropyl tetraether and pentapentyl, which is applied in the field of pentapentyl β-cyclodextrin hydroxypropyl tetraether and its preparation, can solve the problems of poor temperature resistance, acrylamide toxicity, and loss of filtration. In order to solve problems such as poor effect, it can achieve the effect of good high temperature resistance, stable rheological properties, and excellent loss reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides the preparation method of pentapentyl β-cyclodextrin hydroxypropyl tetraether described in the above scheme, comprising the following steps:

[0029] Pentaerythritol and epichlorohydrin are subjected to Wilson reaction under alkaline conditions to obtain pentaerythritol oxypropylene ether;

[0030] The pentaerythroxypropylene oxide ether and β-cyclodextrin are subjected to ring-opening reaction under alkaline conditions to obtain pentapentyl β-cyclodextrin hydroxypropyl tetraether.

[0031] In the invention, pentaerythritol and epichlorohydrin are subjected to Wilson reaction under alkaline conditions to obtain pentaerythritol epoxypropane ether. In the present invention, the molar ratio of pentaerythritol to epichlorohydrin is preferably 1:4.0-4.4, more preferably 1:4.1-4.2.

[0032] In the present invention, the temperature of the Wilson reaction is preferably 3-8°C, more preferably 4-6°C, most preferably 5°C; the time of the Wilson rea...

Embodiment 1

[0044] Dissolve 2.5g of potassium hydroxide in 25ml of deionized water, stir to dissolve fully, add 1.4g of pentaerythritol, heat to 90°C with stirring, react for 2h, then cool to 5°C, add 3.2ml of epichlorohydrin, React at 5°C for 10h (reaction pH is 12), after the reaction is completed, add 48g of β-cyclodextrin and 150ml of sodium hydroxide solution (concentration: 0.033g / ml) to the reaction solution, stir evenly and heat up to 35°C for 24h (The reaction pH is 8.5), after the reaction is completed, the resulting mixed solution is rotary evaporated to about 50 ml to obtain a concentrate, which is washed with 300 ml of acetone, filtered and dried at 45°C for 24 hours to obtain pentapentyl β - Cyclodextrin hydroxypropyl tetraether 46.5 g.

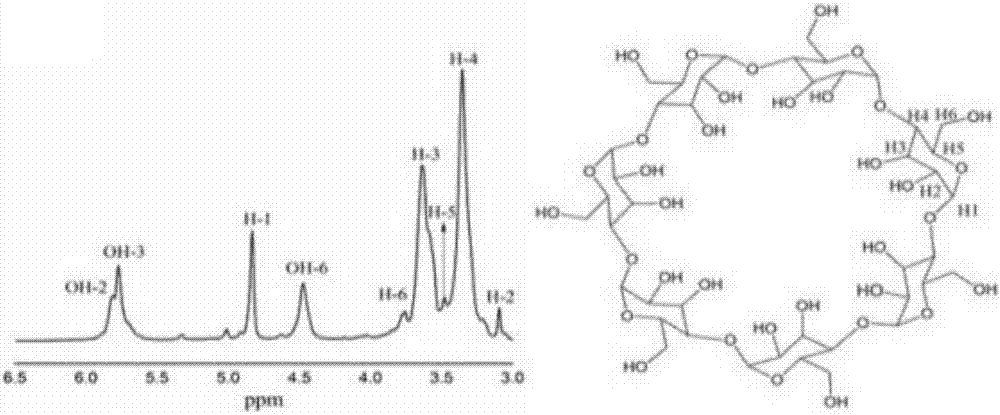

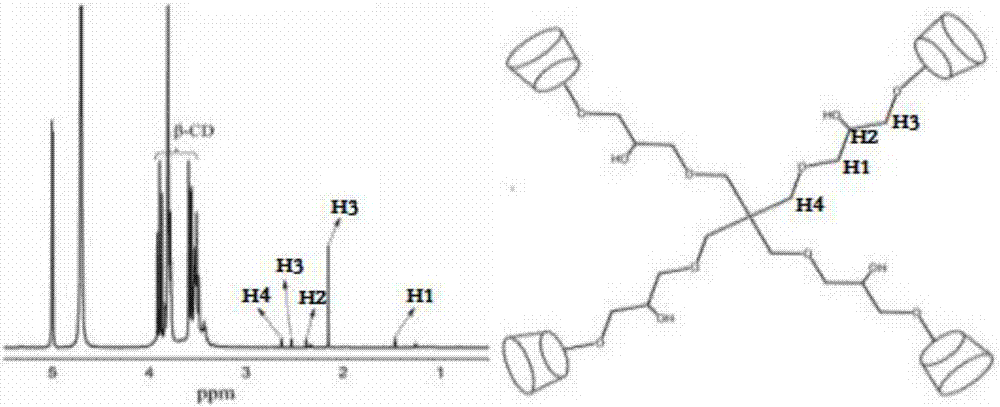

[0045] The structure of β-cyclodextrin and the obtained pentapentyl β-cyclodextrin hydroxypropyl tetraether is analyzed by nuclear magnetic resonance method, and the obtained 1 HNMR spectrum such as Figure 1~2 shown; where figure 1 for ...

Embodiment 2

[0047] Dissolve 2.5g of potassium hydroxide in 15ml of deionized water, stir well to dissolve, add 1.4g of pentaerythritol, heat to 95°C with stirring, react for 1h (reaction pH is 13.5), then cool to 5°C, add 3.78ml Epichlorohydrin, react at 5°C for 8h, after the reaction is completed, add 45g of β-cyclodextrin and 150ml of sodium hydroxide solution (concentration: 0.034g / ml) to the reaction solution, stir evenly and then heat up to 30°C for 22h (The reaction pH is 9.3), after the reaction is completed, the resulting mixed solution is rotary evaporated to about 50 ml to obtain a concentrate, which is washed with 300 ml of acetone, filtered and dried at 45°C for 24 hours to obtain pentapentyl β - Cyclodextrin hydroxypropyl tetraether 45.2 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com