Process for preparing hexahydrophthalic anhydride (HHPA) by means of catalytic hydrogenation

A technology of hexahydrophthalic anhydride and catalytic hydrogenation, applied in the field of chemistry, can solve the problems of increasing market demand for hexahydrophthalic anhydride, easy transfer of double bonds, incomplete hydrogenation, etc., to achieve uniform and controllable reaction layout and avoid local overheating phenomenon, the effect of reducing the occurrence of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

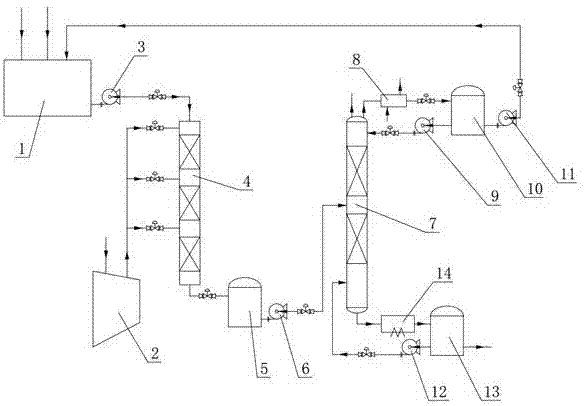

[0014] Reference signs: 1. Mixing tank 2. Hydrogen compressor 3. Feeding pump 1 4. Trickle flow reactor 5. Crude product storage tank 6. Feeding pump 2 7. Distillation tower 8. Total condenser 9. Tower top Reflux pump 10. Tower top storage tank 11. Solvent circulation pump 12. Tower bottom reflux pump 13 Tower bottom storage tank 14. Reboiler.

[0015] First, SiO was treated with supercritical methanol 2 Carrier, to reduce the oxygen-containing groups on its surface, add SiO to 1 L of hydrochloric acid solution with a concentration of 1 2 Carrier, 15-20 wt%; H 2 PdCl 4 , 1~3 wt%, under the temperature condition of 50~80 ℃, fully stirred for 8~10 h to get Pd / SiO 2 , dried in vacuum at 80°C for 10-12 h, and set aside.

[0016] Take 0.5 Kg Pd / SiO 2 , add nickel nitrate according to 5-8 wt%, add 1 L of distilled water, under the condition of constant temperature water bath at 80 ℃, fully stir for 8-10 h, and vacuum dry at 80 ℃ for 10-12 h. Then calcined at 500 °C for 6 h to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com