Waterproof and anti-alkali decorating mortar and preparation method thereof

A decorative mortar and quartz sand technology, applied in the field of building materials, can solve the problems of high water absorption and efflorescence, and achieve the effects of low water absorption, high density, and low risk of efflorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of the present invention is described below with specific examples, but protection scope of the present invention is not limited thereto:

[0027] A waterproof and alkali-resistant decorative mortar, the preparation process is as follows:

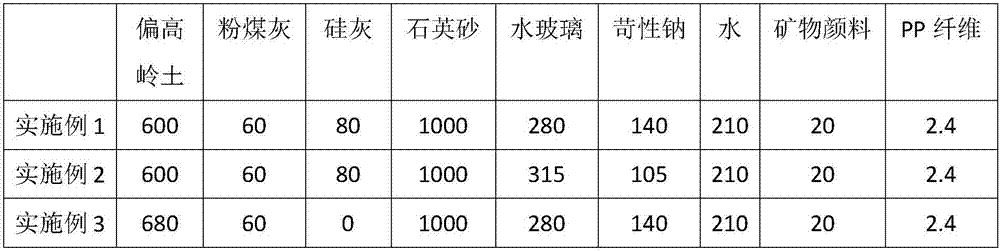

[0028] 1) The design coordination ratio is shown in Table 2, and the raw materials are prepared according to the data in the table;

[0029] The metakaolin is a white 1250-mesh superfine powder, and its composition is the same as in Table 1.

[0030] The fly ash is preferably grade II or above ash, the silica fume is white 800 mesh silica powder, and the quartz sand adopts three specifications of 20-40 mesh, 40-70 mesh, and 325 mesh in a mass ratio of 9 : 3:1 mixed to obtain; said water glass modulus is 2.0-2.5; the length of pp fiber is 3mm.

[0031] 2) Prepare the activator: mix the required caustic soda with water, stir and dissolve for 10 minutes, then add the required water glass and stir evenly, then let ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com