Printing method of 3D product, and 3D printer used in method

A 3D printer and product technology, applied in the field of print heads, can solve the problems of error, rubber strip precision traction error, low precision, etc., and achieve the effect of simplifying circuit control, improving the accuracy of 3D products, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

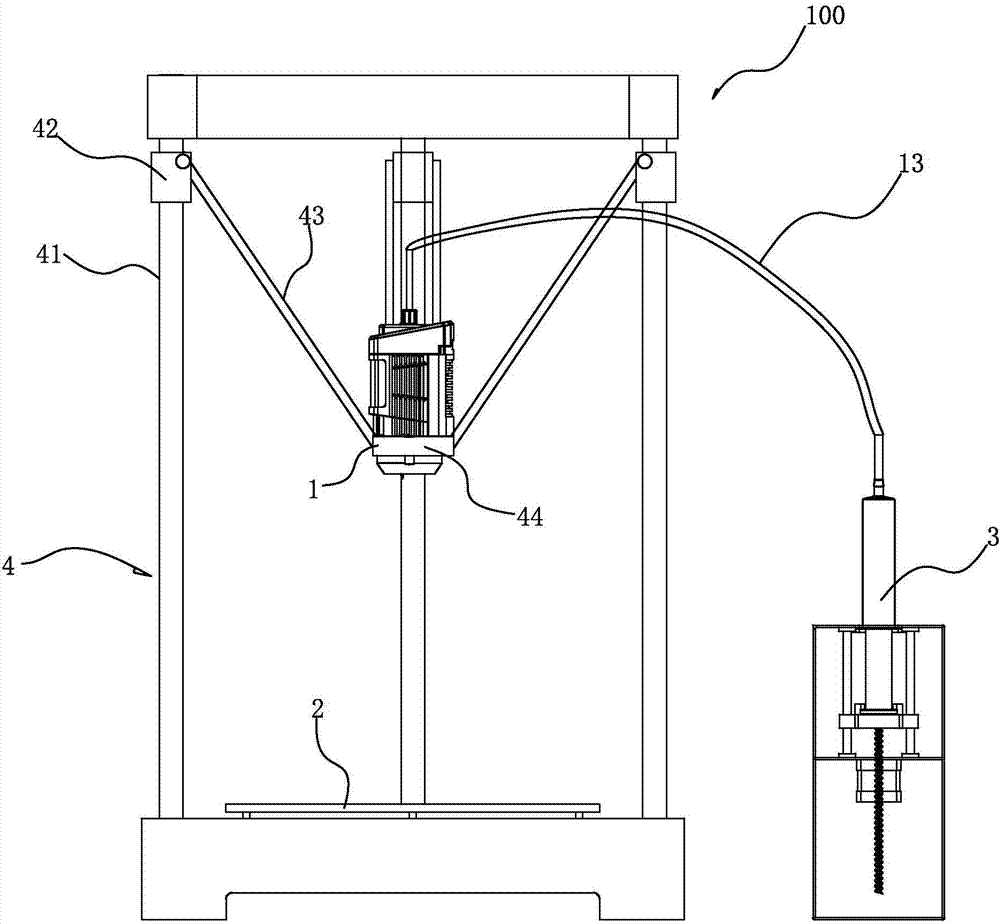

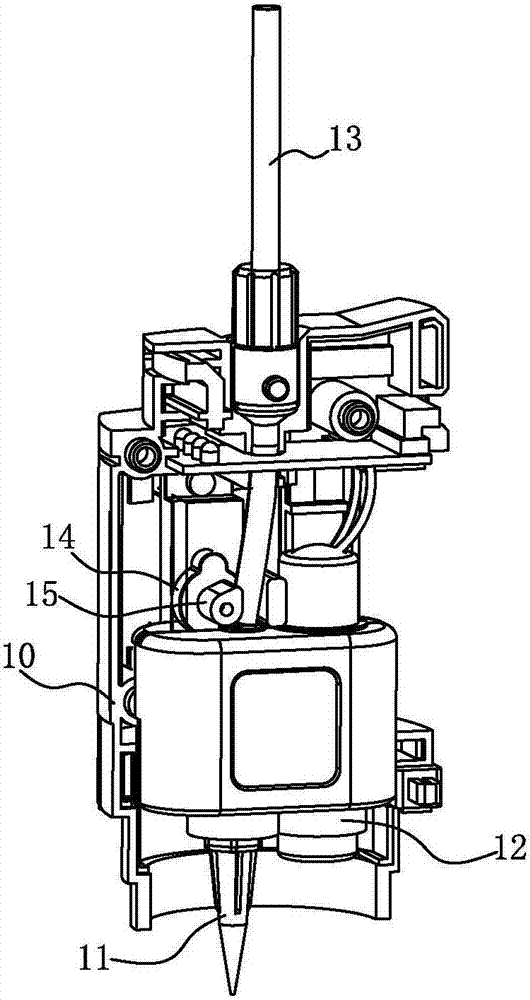

[0031] See Figure 1-4 As shown, this is a 3D printer in the present invention, which includes: a print head 1, a printing platform 2, and a container 3 that provides printing materials for the print head 1, and the print head 1 can pass through in the X / Y / Z direction The upper moving mechanical arm 4 is suspended above the printing platform 2 .

[0032] The mechanical arm 4 used in the present invention is a delta robotic arm (Delta Robot), this mechanical arm generally has 3-4 degrees of freedom, can realize running on the X / Y / Z direction, and around the Z axis direction rotate. The triangular manipulator has been recorded in many patent documents as a technology that has been maturely used. See the US patent documents with patent publication numbers US 8621953 B2, US 20120103124 A1, US20120171383 A1, and 20130049261A1, all of which propose re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com