Conveying method and system device of side wires obtained by cutting of welding machine

A technology of conveying device and welding machine, which is used in shearing devices, accessories of shearing machines, conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

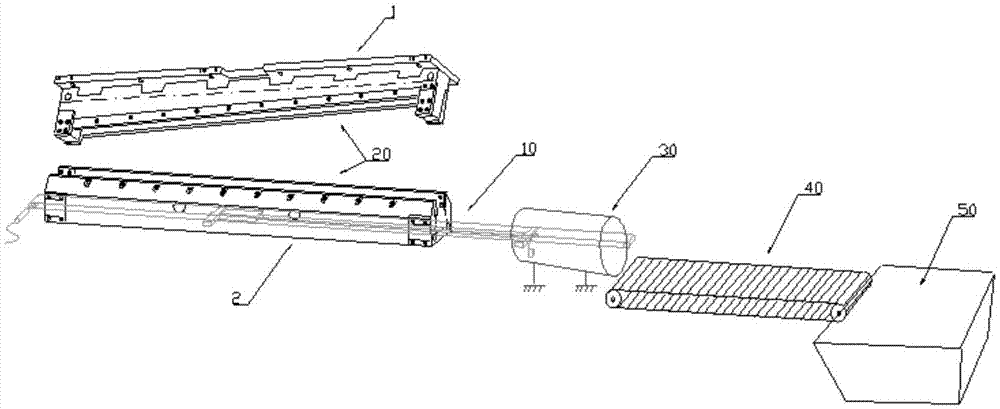

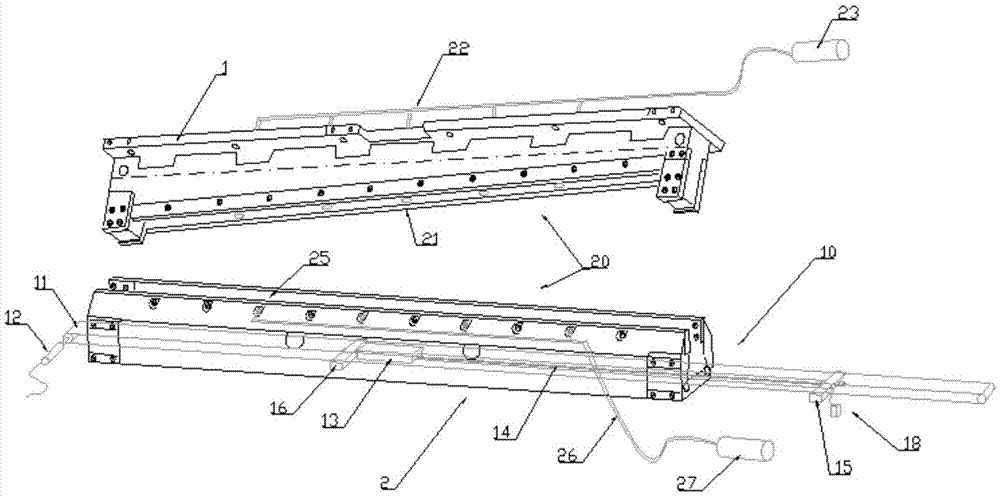

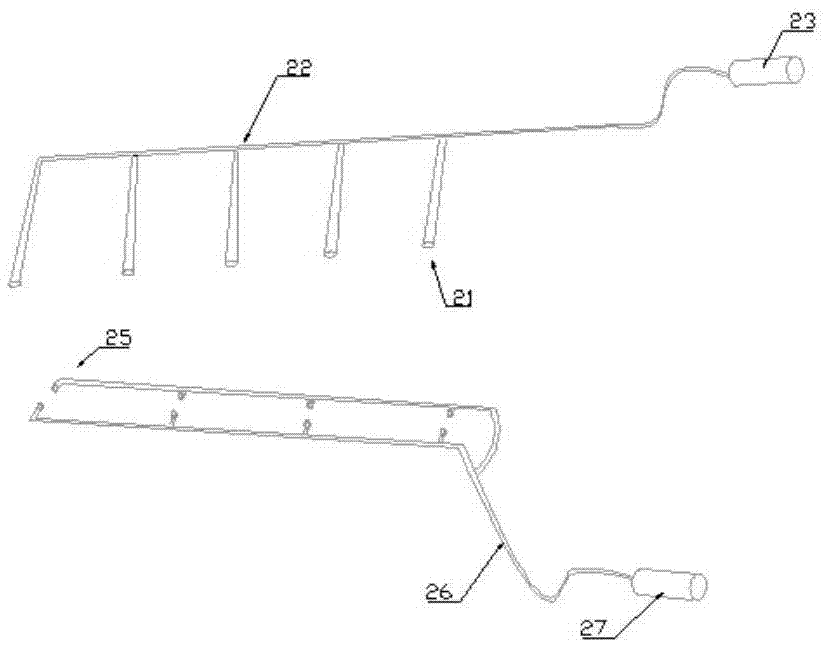

[0050] High-efficiency conveying system for welding machine cutting side wire. During the secondary shearing process of the welding machine, compressed gas is injected into the built-in nozzle of the upper scissors, and the cut side wire is blown down to the waste belt inside the lower scissors. The lower scissors The side nozzle sprays compressed gas at the same time to blow the falling edge wire to the middle of the waste belt to prevent it from being stuck into the belt when it is at the edge of the belt. 2 seconds before the end of the blowing, the magnetic suction cup is energized to generate magnetic adsorption to cut the edge wire, and the suction cup drives the wire. The rod assembly and the waste belt move synchronously, conveying the sucked cut edge wire to the end of the waste belt, and at the same time the suction cup is powered off to release the edge wire, and the edge wire enters the limit guide blowing part with the running belt, and the part blows compressed gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com