Preparation method of mercury removal adsorbent for Indonesian oil sand tailings

A technology of adsorbent and tailings, which is applied in the field of preparation of adsorbents for mercury removal from oil sand tailings in Indonesia, can solve the problems of occupying land, polluting the environment, waste of resources, etc., and achieves low preparation cost, simple preparation method and high adsorption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

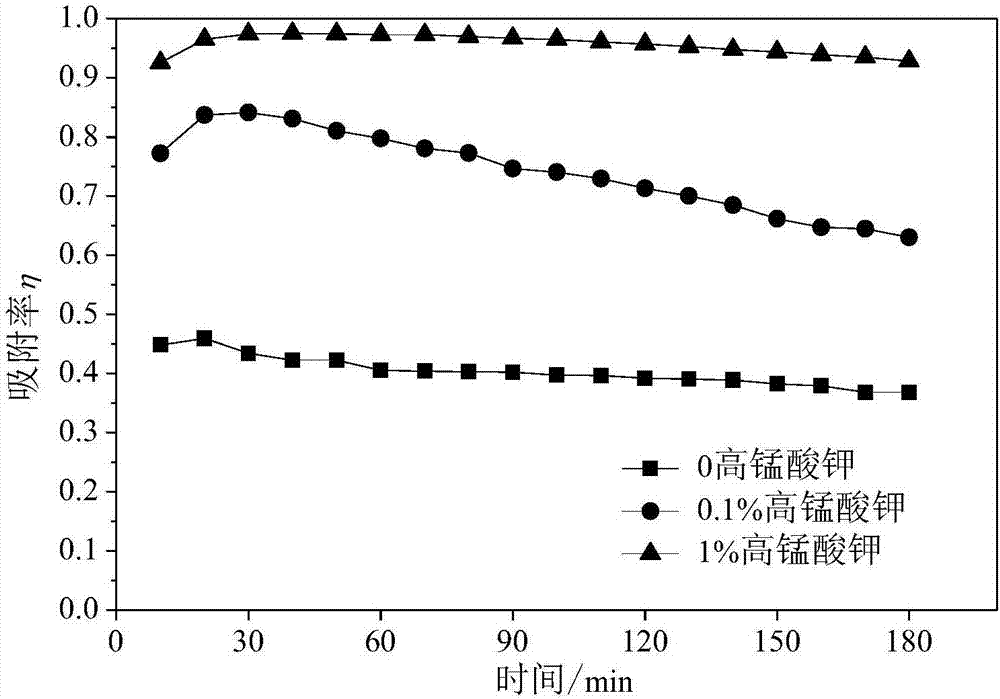

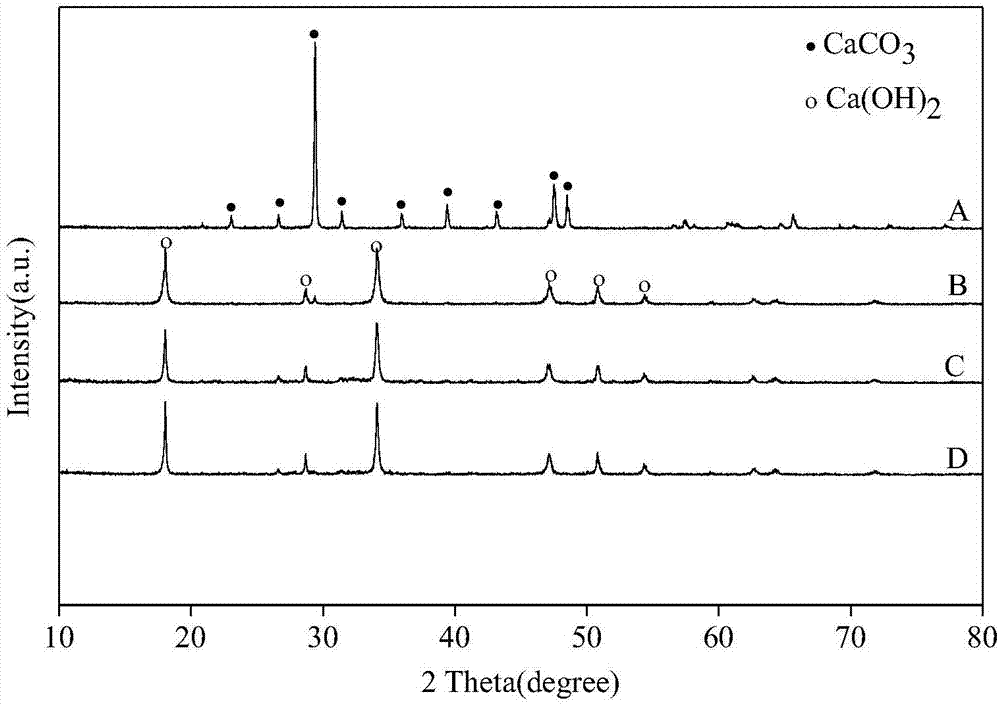

Embodiment 1

[0032] The oil sand tailings produced in Indonesia are used as raw materials, and its composition contains CaCO 3 , crush the oil sand tailings into powder, sieve the part below 20 mesh (large particles continue to be pulverized), and then put the sieved oil sand tailings powder in a muffle furnace, at 900 ° C Burn for 4 hours, then cool it down to room temperature; mix burnt oil sand tailings powder and water at a mass ratio of 1:6, and carry out digestion reaction at 80°C for 4 hours; put the reaction product in an oven, It is dried at 105°C, and the dried product is ground into powder to obtain the adsorbent for mercury removal of oil sand tailings.

Embodiment 2

[0034] The oil sand tailings produced in Indonesia are used as raw materials, and its composition contains CaCO 3, crush the oil sand tailings into powder, sieve the part below 20 mesh (large particles continue to be pulverized), and then put the sifted oil sand tailings powder in a muffle furnace, at 900 ° C Burn for 4 hours, then cool it down to room temperature; mix the burnt oil sand tailings powder and water at a mass ratio of 1:6, then add 0.1% potassium permanganate by mass percentage, and then The reaction was carried out at ℃ for 4 hours; the reaction product was put into an oven, dried at 105 ℃, and then the dried product was ground into powder to obtain the adsorbent for mercury removal of oil sand tailings.

Embodiment 3

[0036] The oil sand tailings produced in Indonesia are used as raw materials, and its composition contains CaCO 3 , crush the oil sand tailings into powder, sieve the part below 20 mesh (large particles continue to be pulverized), and then put the sifted oil sand tailings powder in a muffle furnace, at 900 ° C Burn for 4 hours, then cool it down to room temperature; mix the burnt oil sand tailings powder and water at a mass ratio of 1:6, then add 1% potassium permanganate by mass percentage, and then The reaction was carried out at ℃ for 4 hours; the reaction product was put into an oven, dried at 105 ℃, and then the dried product was ground into powder to obtain the adsorbent for mercury removal of oil sand tailings.

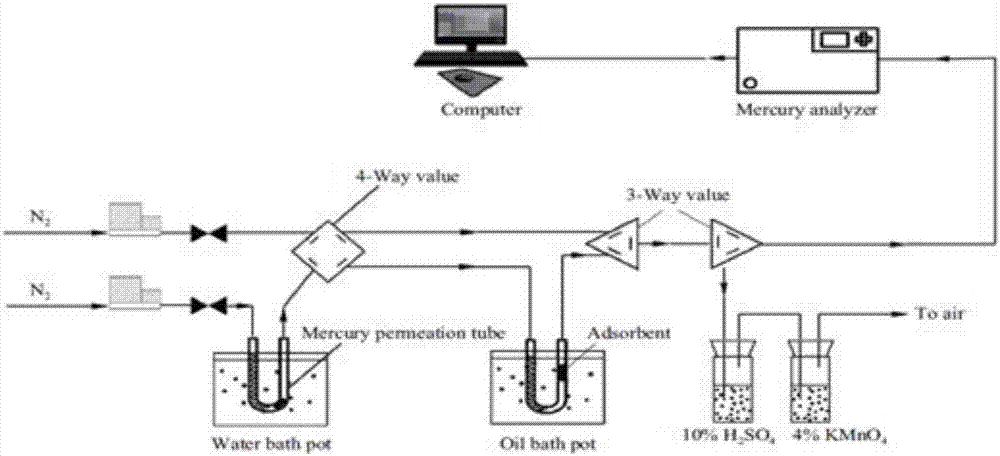

[0037] The oil sand tailings adsorbent prepared in Examples 1 to 3 was used under the condition of adsorption temperature of 140°C and loading capacity of 1g figure 1 The shown small-scale fixed-bed mercury adsorption experiment device was used for mercury rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com