Oral care compositions containing biodegradable particles with superior aesthetics

A technology for oral care and biodegradation, applied in the fields of promoting oral health and preparing oral care compositions, which can solve undesirable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

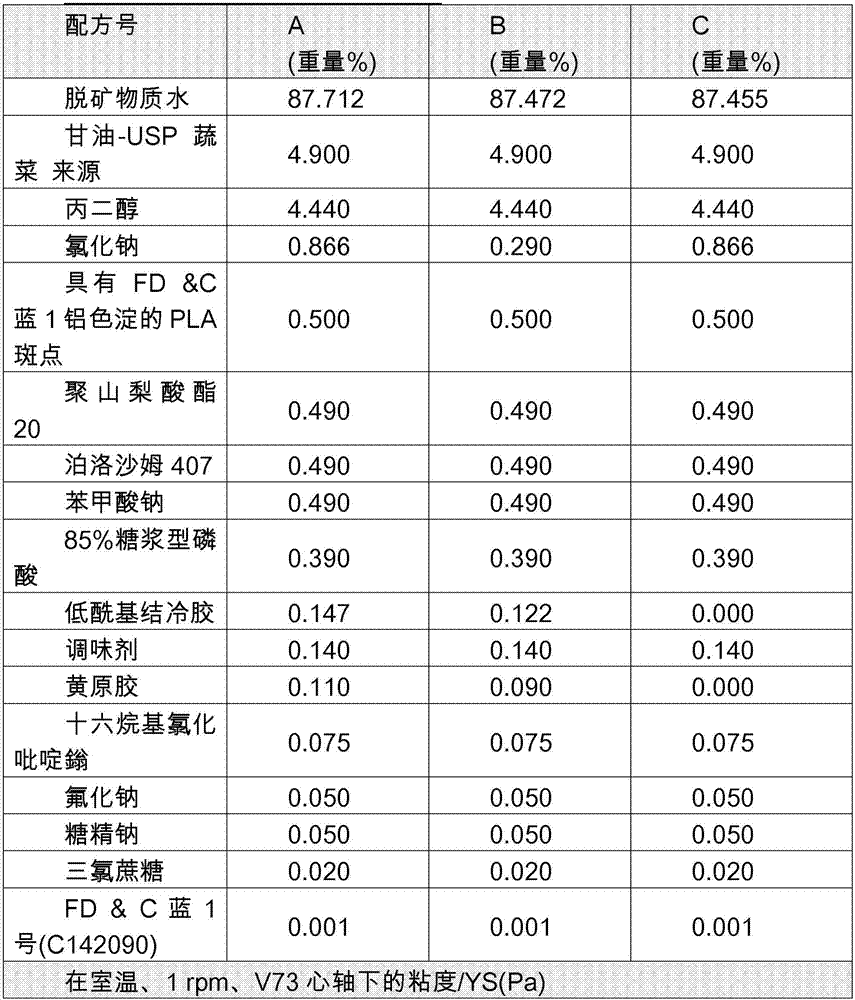

[0095] Example 1 - Structured Mouthwash

[0096] Three mouthwash formulations A, B and C were prepared by mixing the ingredients described in Table 1 below. Formulations A and B as shown in Table 1 with a combination of xanthan gum (0.110% by weight, Formulation A and 0.090% by weight, Formulation B) and gellan gum (0.147% by weight, Formulation A and 0.122% by weight, Formulation B) Be structured. Formulation C contains no gum component. NaCl was used to achieve viscosities in the range of 255 to 595 (reported in centipoise (cps) in Table 1, where 1 cps = 0.001 Pa·s). 0.5% by weight of FD&C Blue No. 1 aluminum lake (approximately 230 μm in diameter) encapsulated in polylactic acid was added to each formulation. Encapsulated particles were obtained from MicroPowders, lnc., Tarrytown, NY.

[0097] The viscosity of the mouthwash formulations was measured at 25°C at 1 rpm using a Brookfield Viscometer Model HADV-II+Pro (available from Brookfield Engineering Laboratories, Mi...

Embodiment 2

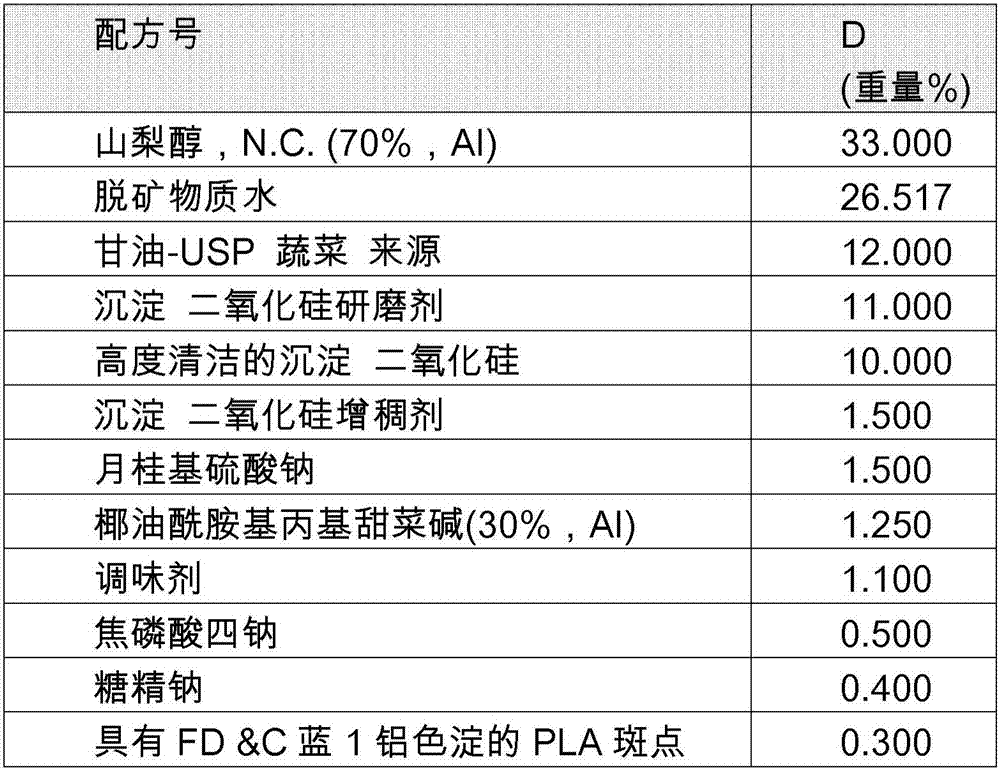

[0112] Example 2. Aqueous gel toothpaste

[0113] An aqueous gel toothpaste having a mouthwash breath freshening component and a toothpaste cleansing component was prepared by mixing the ingredients described in Table 2. 0.3 wt% PLA spots were added to the formulation. Viscosity and YS values are determined as described above.

[0114] As indicated in Table 2, the final viscosity of the formulations ranged from 120,000 to 270,000 cps. The pH is in the range of 7.0 to 9.0.

[0115] PLA flecks have similar specific gravity values to the continuous phase of toothpaste. A uniform distribution of PLA spots was maintained during the storage period of three months. Without being limited by theory, evenly distributed spots are provided by low concentrations of silica thickener and xanthan gum, which contribute to the static yield stress of the formulation ( YS). PLA spots remained intact in this formulation after three months of aging under accelerated conditions.

[0116...

Embodiment 3

[0119] Example 3. Aqueous toothpastes and gels

[0120] will have white (TiO 2 ), blue (FD&C Blue Lake 1, combination of green (FD&C Blue Aluminum Lake, D&C Yellow 5 Lake), and red (FD&C 40 / lake) PLA spots formulated in aqueous toothpaste or gel formulations to assess robustness and / or the compatibility of these formulations with different ingredients. Formulations E-H as shown in Table 3 were prepared by mixing the indicated ingredients. Viscosity and YS were determined as above except that due to the higher viscosity of the formulations the Smaller (V74) guide vane blades to ensure the maximum torque capacity of the instrument is not exceeded.

[0121] As noted in Table 3, the final viscosity of the formulations ranged from 226,000 to 554,000 cps and the pH ranged from 7.33 to 8.05. As also indicated in the table, three month aging evaluations under controlled room temperature and accelerated high temperature conditions resulted in acceptable chemically and physically st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com