Device and method for testing influence of different metal materials on SF6 local sudden discharge fault decomposing

A technology of metal materials and experimental devices, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

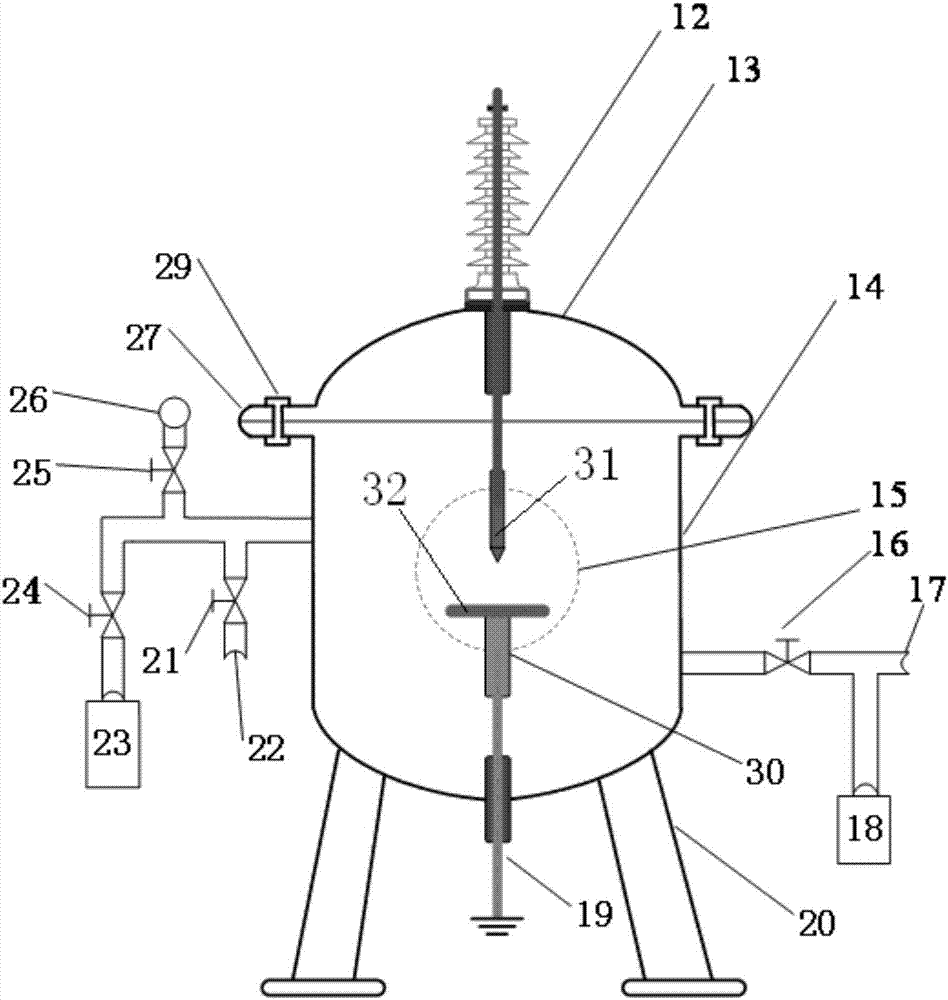

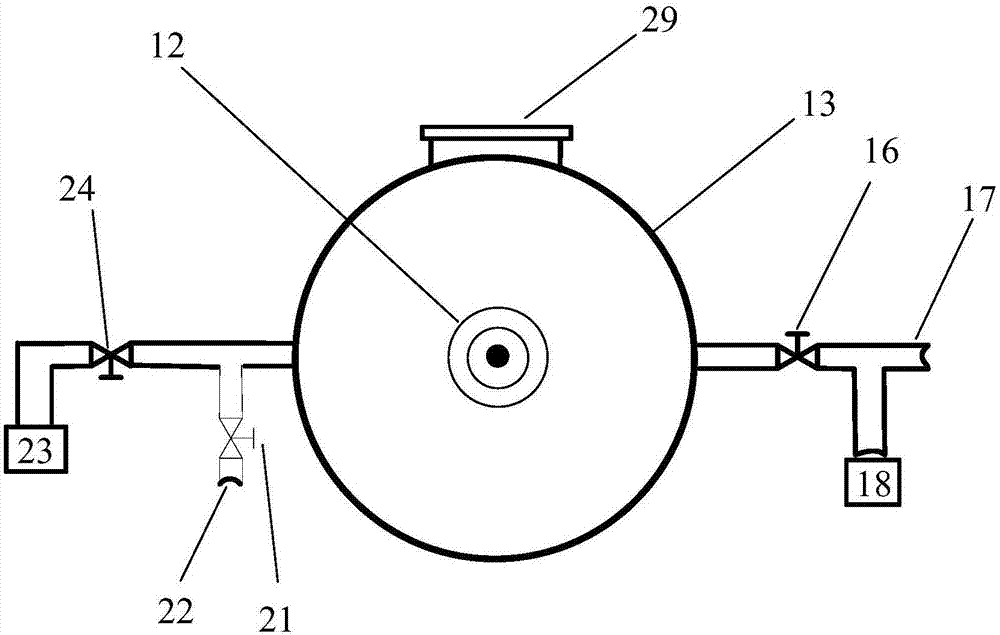

[0041] A different metal material to SF 6 Experimental setup for the effect of spark discharge decomposition. Mainly include: pressurized system, SF 6 Discharge gas chamber, inspection system and protruding defect models for different metallic materials. It is characterized in that in the protrusion defect models of different metal materials, the high-voltage needle electrodes are made of tungsten metal, and the low-voltage plate electrodes are made of pure aluminum, brass and 18 / 8 stainless steel respectively, and in the different metal materials mentioned above Material vs. SF 6 The effects of spark decomposition were tested separately in the experimental setup.

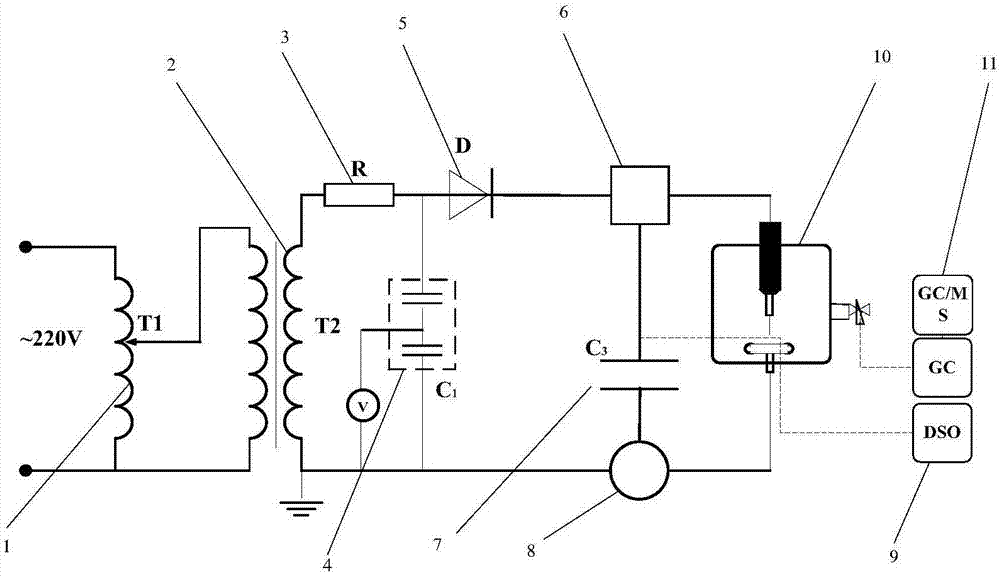

[0042] The pressurization system is composed of a voltage regulating transformer, a high-voltage halo-free experimental transformer, a high-voltage rectifying silicon stack, a filter capacitor, a capacitor voltage divider and a protection resistor. The input end of the voltage regulating transformer 1 is connec...

Embodiment 2

[0048] A different metal material to SF 6 The experimental device for the impact of spark discharge decomposition is the same as in Example 1. Needle electrode 31 is made of pure tungsten. The main body of the needle electrode is made of brass. The total length is 60mm. It is connected to the high-voltage SF6 / air bushing 12 through the internal threaded hole; the plate electrode 32 is made of 18 / 8 stainless steel, and its shape is round, with a diameter of 100 mm and a thickness of 10 mm. catch. The needle-plate spacing can be adjusted through the lifting thread between the grounding metal rod 19 and the grounding conductive rod 30, so that the needle-plate spacing can be adjusted within the range of 0-40mm.

Embodiment 3

[0050] A different metal material to SF 6 The experimental device for the impact of spark discharge decomposition is the same as in Example 1. Needle electrode 31 is made of pure tungsten. The main body of the needle electrode is made of brass. The total length is 60mm. And it is fixedly connected with the high-voltage SF6 / air bushing 12 through the inner threaded hole; the plate electrode 32 is made of pure aluminum, its shape is circular, the diameter is 100mm, and the thickness is 10mm, and it is fixed with the grounding conductive rod 30 through the inner threaded hole. The needle-plate spacing can be adjusted through the lifting thread between the grounding metal rod 19 and the grounding conductive rod 30, so that the needle-plate spacing can be adjusted within the range of 0-40mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com