Preparing device and method of double-layer laminated carbon fiber composite

A composite material and preparation device technology, applied in the field of machine manufacturing, can solve the problems of insufficient stability of materials, large turnover error, and complicated coordination, and achieve the effects of improving turnover accuracy, improving production efficiency, and reducing required time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

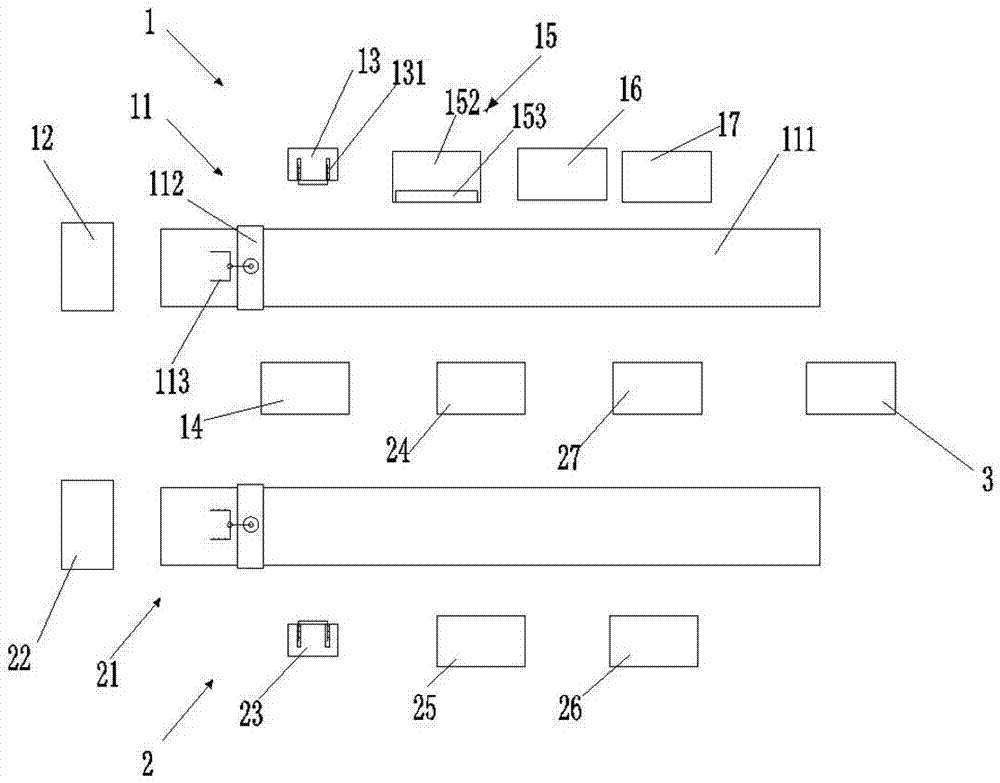

[0032] see Figure 1 to Figure 4 , a preparation device for double-layer laminated carbon fiber composite materials, comprising a thin-walled surface member production device 1 for producing thin-walled surface members, and a thin-walled surface member production device 1 arranged in parallel and used for producing support supporting member production device 2 for the component and a mold gluing device 3 for gluing said thin-walled surface member and supporting member to each other;

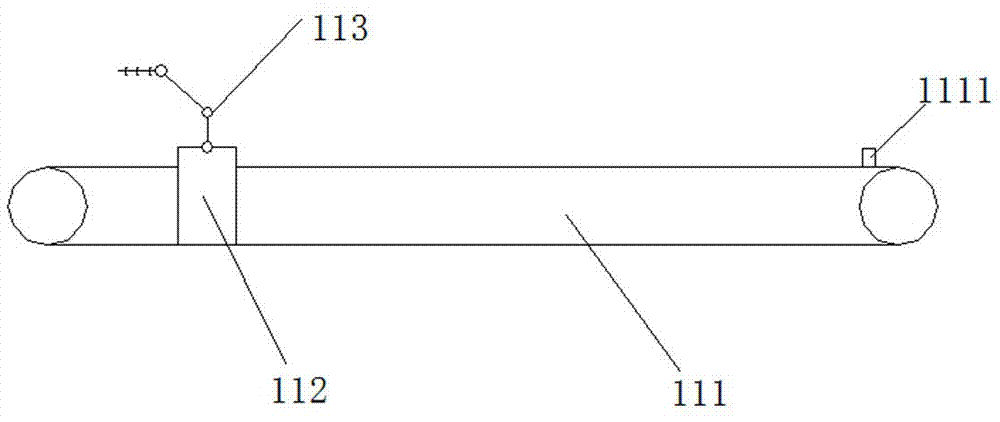

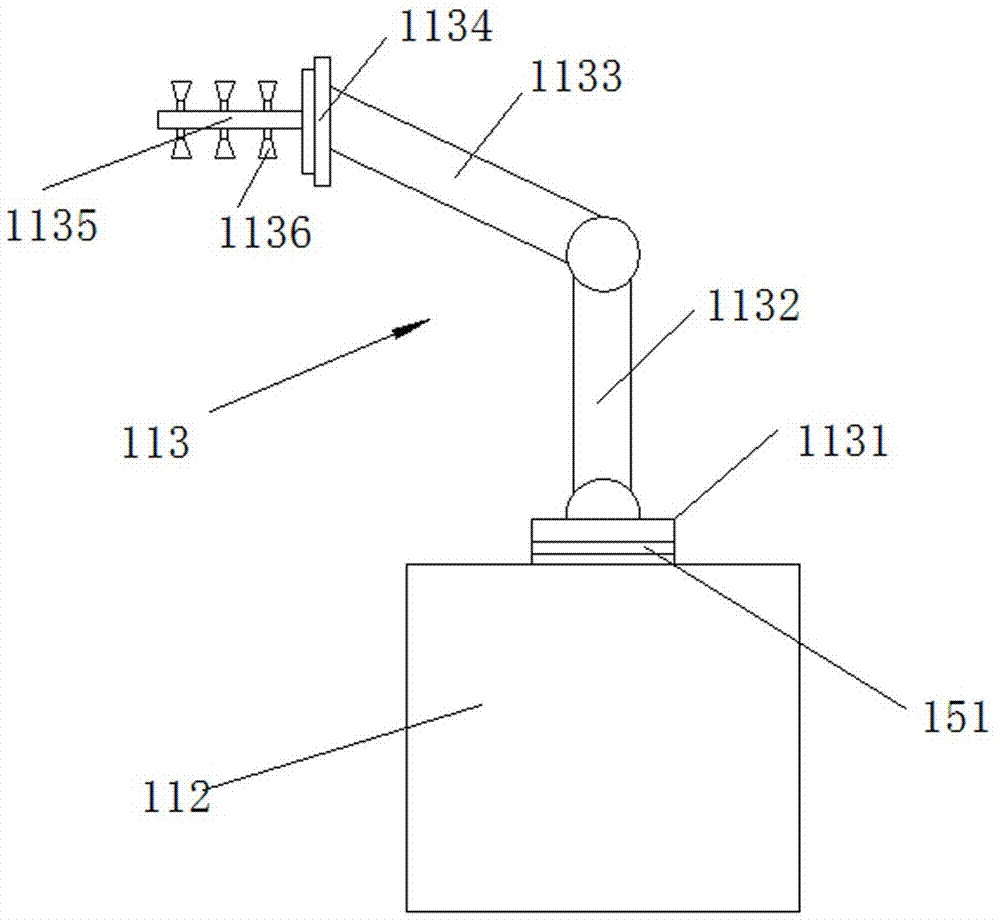

[0033]The thin-walled surface member production device 1 includes a first automatic transfer device 11 and a thin-walled surface member forming device 12 for forming a thin-walled surface member arranged on the side of the first automatic transfer device 11, a first turning table 13, a cooling The first cooling device 14 of the thin-walled surface member, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com