Wet-type dust removal equipment for clearing combustible dust and precipitates and dust removal method

A technology for wet dust removal and dust removal equipment, which is applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of increasing daily workload, consuming large water resources, and high maintenance costs, and reducing on-site monitoring operation steps. And the effect of daily workload, reduction of manual transportation steps, and reduction of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

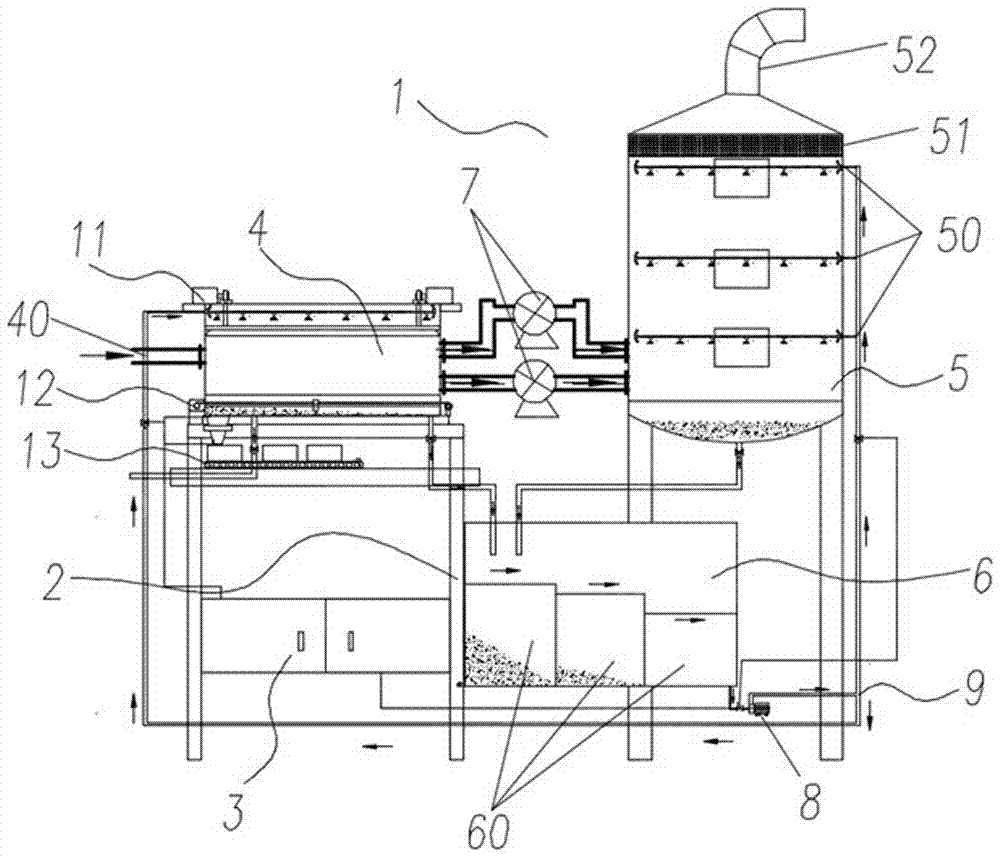

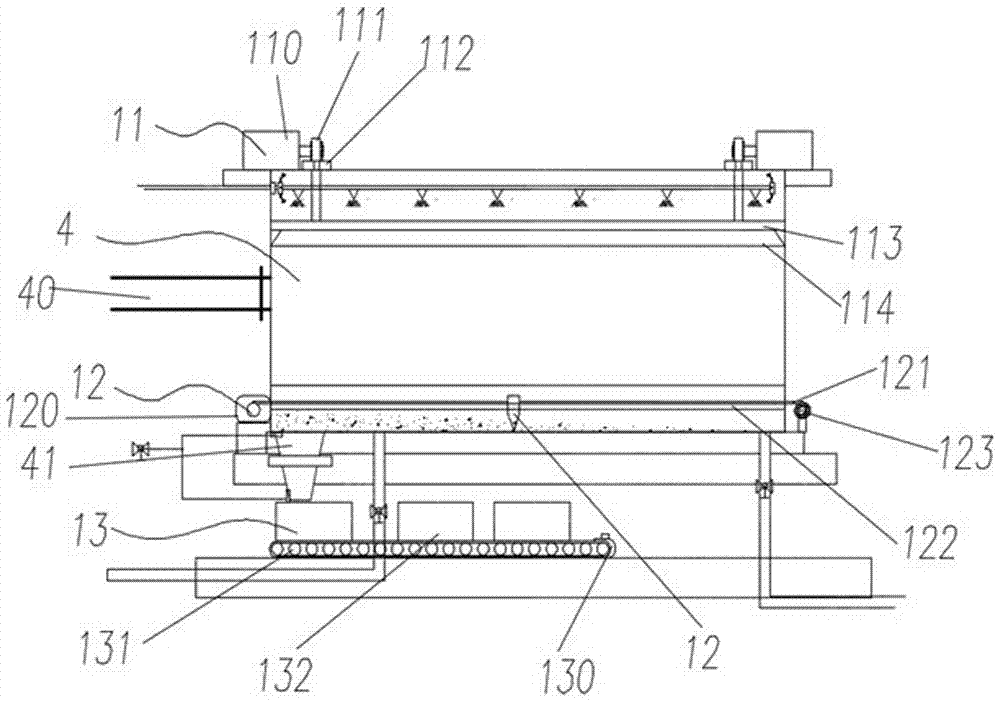

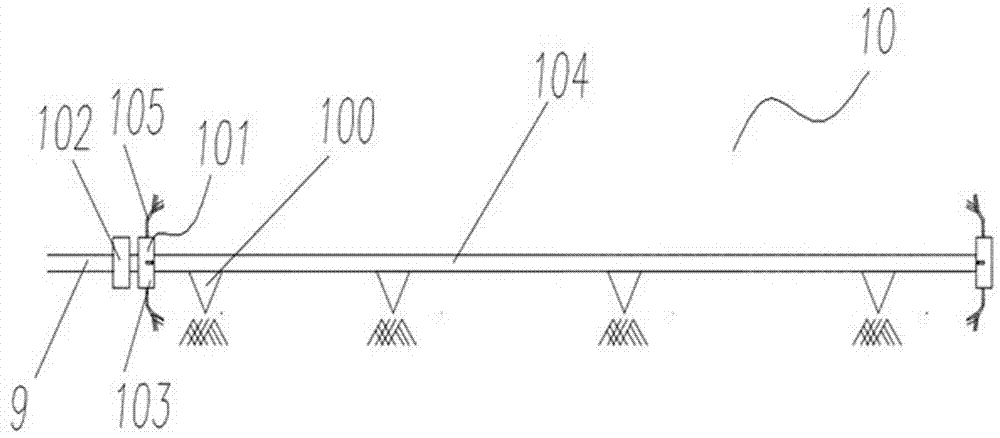

[0031] See attached Figure 1~3 , Embodiment 1, the whole 1 of the wet dust removal equipment for combustible dust and sediment removal includes a fixed bracket 2, a control electric box 3, a first spray box 4, a second spray box 5, a three-stage sewage filter pool 6, Two explosion-proof centrifugal fans 7, explosion-proof high-pressure water pump 8, the first spray box 4 is arranged on the upper left side of the fixed bracket 2, the second spray box 5 is arranged on the upper right side of the fixed bracket 2, and the three-stage Sewage filter tank 6 is set and placed below the fixed frame 2, and two explosion-proof centrifugal fans 7 are arranged between the first spray box 4 and the second spray box 5, and the effect of the two explosion-proof centrifugal fans 7 is to act as a set When a failure occurs, it ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com