Quick-forming wear-resistant and durable injection mold

An injection mold, a durable technology, applied in the field of injection molding, can solve the problem of poor fusion of injection molded objects and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0042] As shown in how to 1 to 15, in order to solve the technical problem of "how to gradually cool the injection molding during the injection molding process, so that the cooled injection molding and the uncooled injection molding have time for better contact fusion", the following is a kind of technical problem. The structure and function of rapid prototyping wear-resistant and durable injection molds are explained in detail;

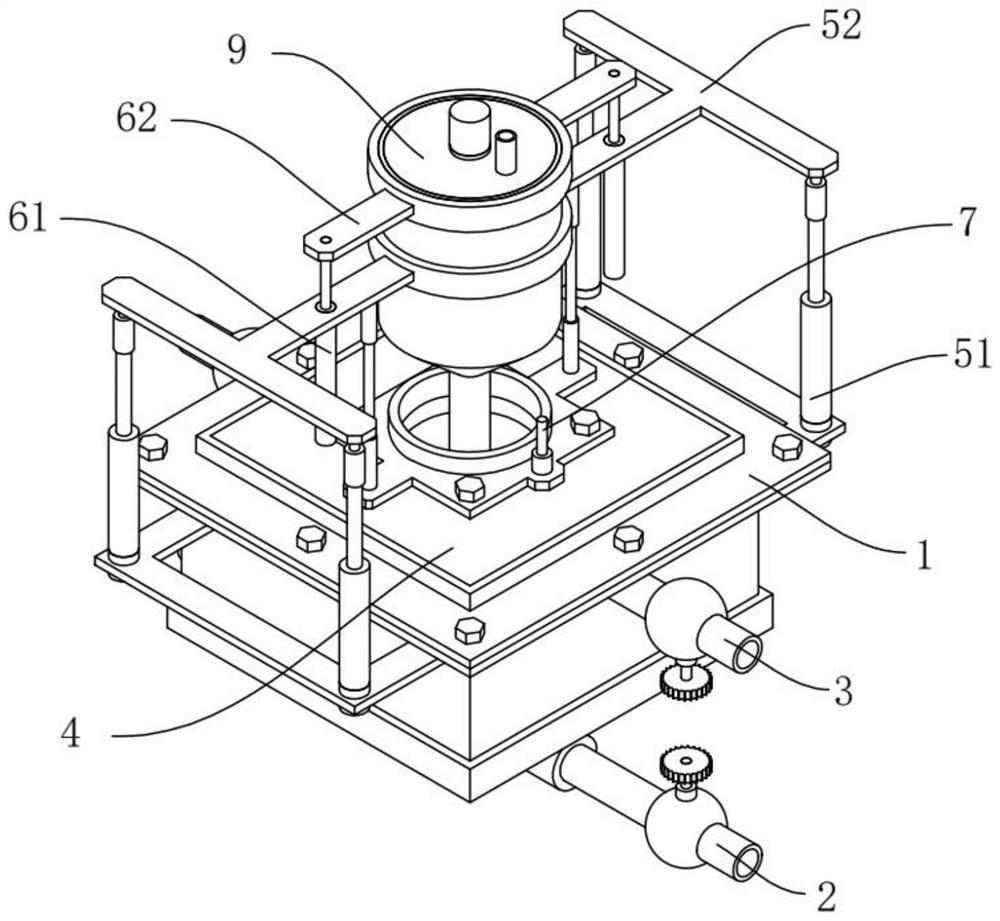

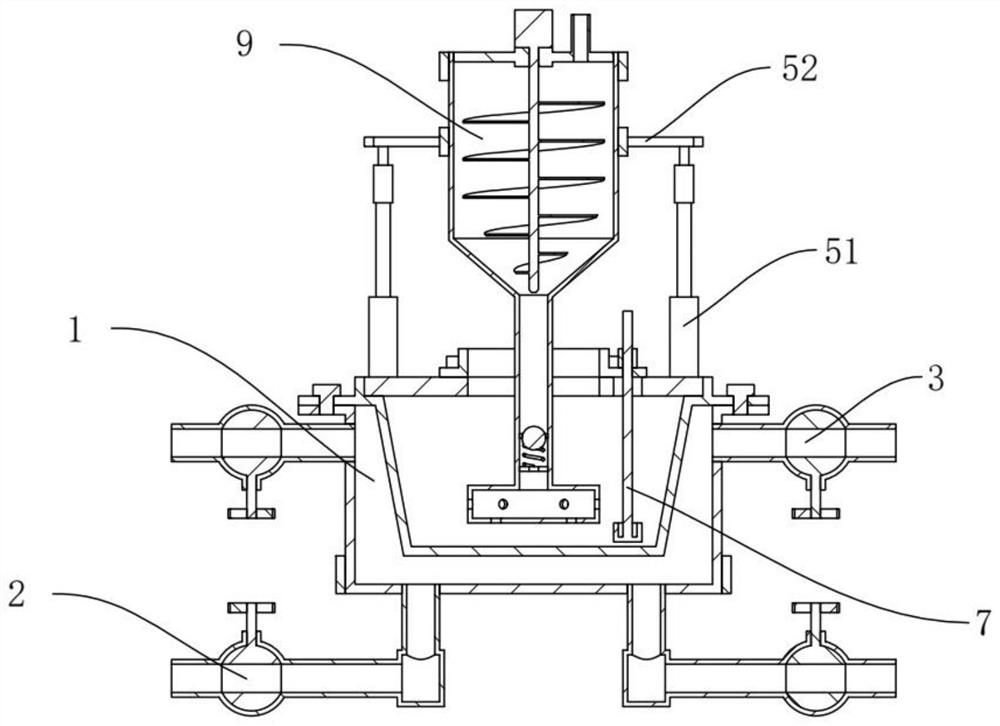

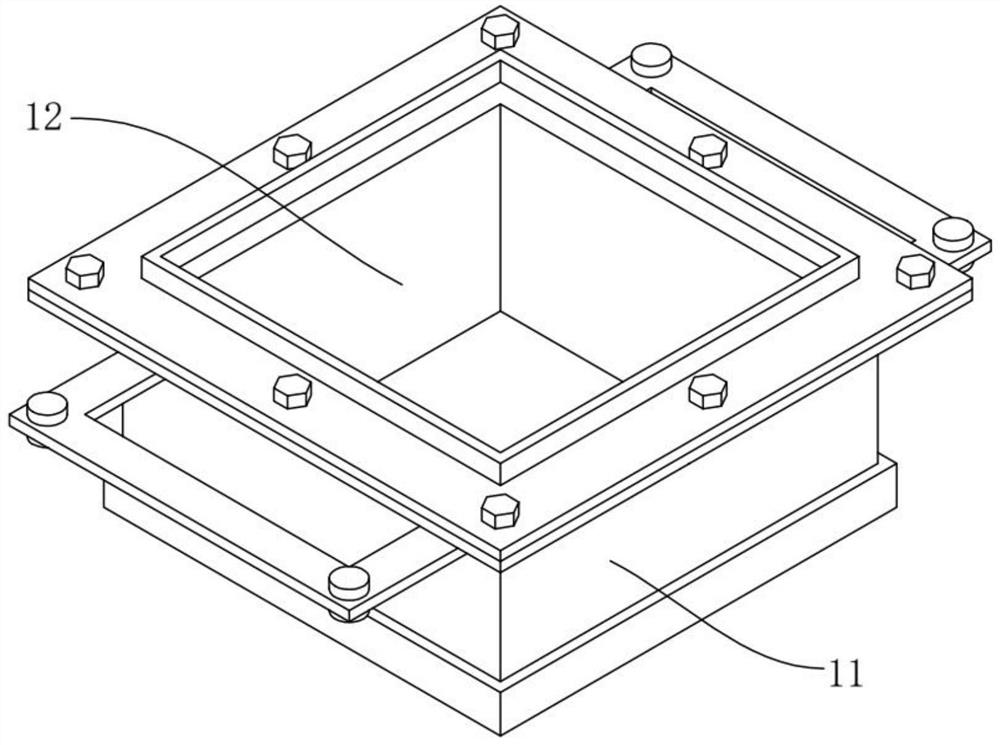

[0043] A rapid prototyping wear-resistant and durable injection mold, comprising a bottom mold 1, a pipe mechanism I2, a pipe mechanism II3, a cover mechanism 4, a first telescopic mechanism 51, a lifting plate I52, a second telescopic mechanism 61, a lifting plate II62, measuring Mechanism II7, sensor II8 and injection mechanism 9;

[0044] When in use, the capping mechanism 4 is driven to move by the first telescopic mechanism 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com