Wet etching device, wet etching method and wafer chip

A wet etching, wafer technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as difficult to control, low efficiency, wafer surface contamination, etc., to achieve high speed, reduce The effect of surface contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] First, a photoresist is coated on the surface of the wafer, and then the desired pattern is obtained on the surface of the wafer through a photolithography process. The surface of the wafer causes a chemical reaction of the photoresist in the exposed area, and then dissolves and removes the photoresist in the exposed or unexposed area by developing technology, so that the pattern on the mask plate is copied to the photoresist film, and finally uses Wafers are patterned using wet etching techniques.

Embodiment 2

[0085] The area where the metal film is not needed is covered with photoresist, and the surface of the wafer is covered with a layer of metal by the method of coating, so that the metal film is only connected to the substrate in the required area, and finally placed on the wet etching device , Through the wet etching device, the fluidity of the stripping solution is increased, and the impact kinetic energy of the stripping solution on the wafer is improved, which effectively improves the stripping rate of the photoresist, thereby improving the uniformity of corrosion (metal stripping). As the photoresist dissolves, the metal on it also falls off, leaving the desired metal pattern.

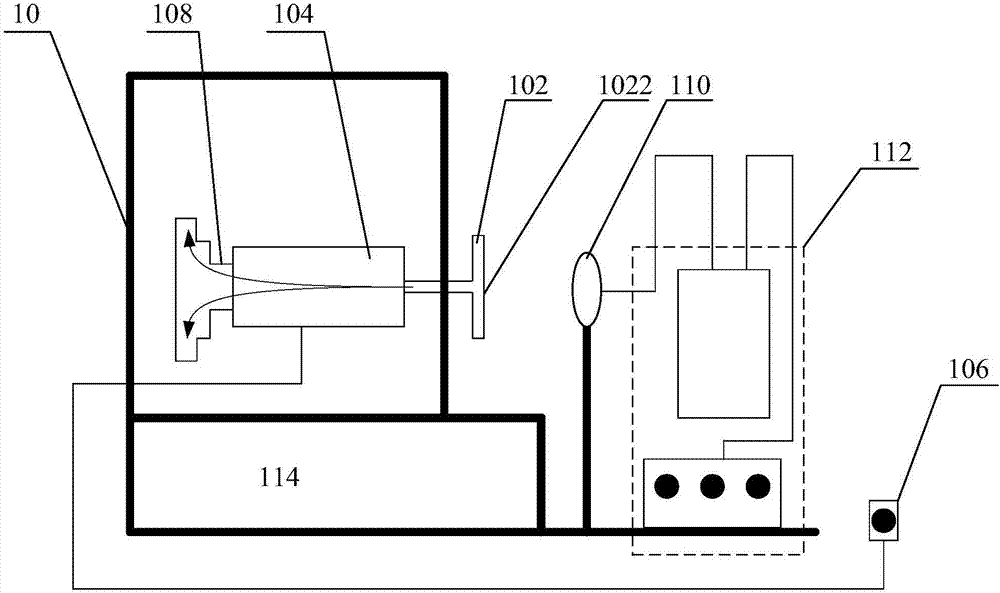

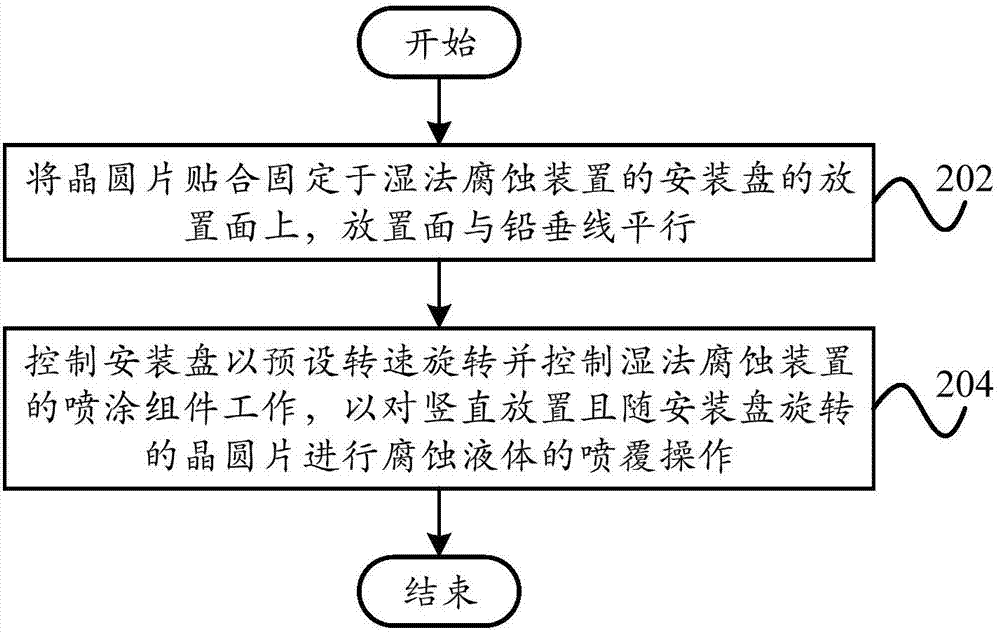

[0086] combine figure 1 and figure 2 As shown, in any of the above-mentioned embodiments, preferably, a wet etching device is used to wet-etch the wafer, which specifically includes: step 202, attaching and fixing the wafer to the mounting plate 102 of the wet-etching device On the placement sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com