Local thermal-resistance testing system applied to perspiring fabric thermal manikin

A thermal manikin, local technology, applied in the field of local thermal resistance test system, to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

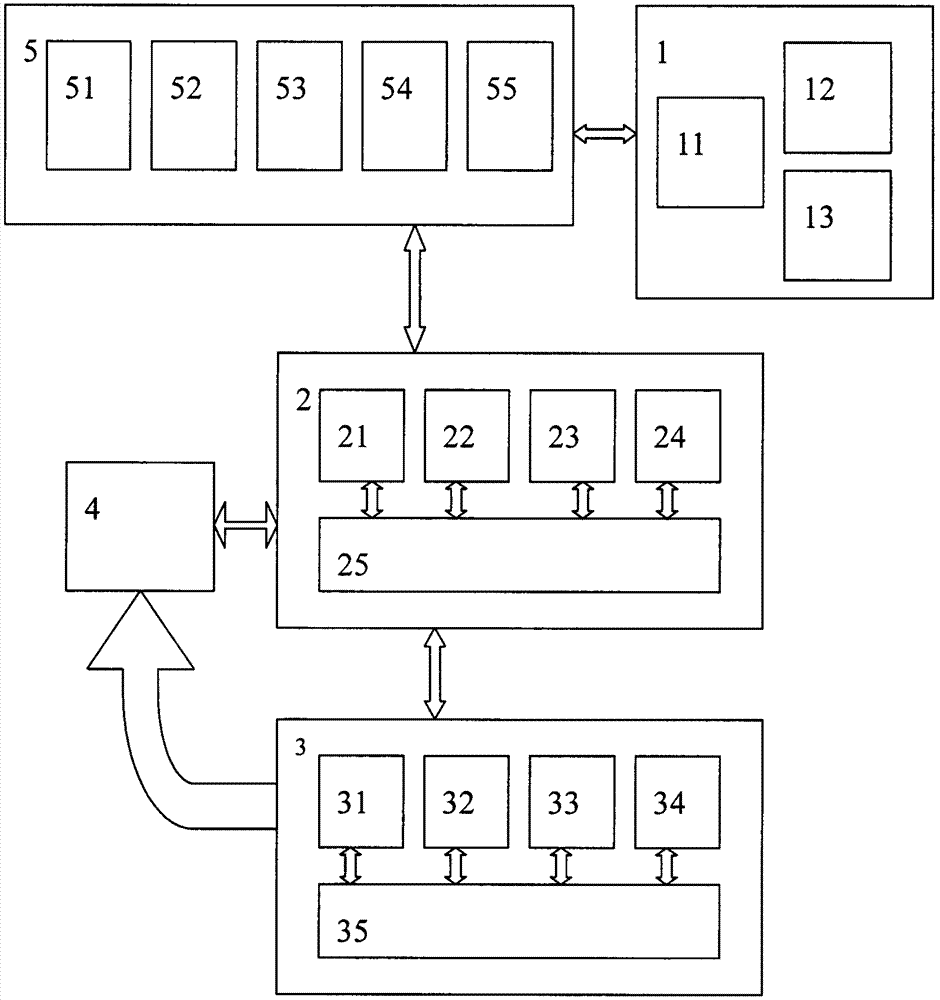

[0023] Taking a fabric sweating warm body manikin as an example, the temperature measurement sensor array module 31, the heat flux sensor array module 32, the humidity sensor array module 33, and the pressure sensor module 34 in the multi-sensor array and wireless transmission module 3 are used for the dummy. For local thermal resistance test, the data to be tested includes heat flow density, temperature, humidity and surface pressure of dummy skin, and the data is transmitted to local thermal resistance field data through wireless transmission module 35, multi-sensor array and wireless transmission module local bus 36 In the local thermal resistance analog signal acquisition card module 21 and the digital control signal acquisition card module 22 in the acquisition module 2, the network signal connection module 23 is responsible for judging the correctness of the network connection. If it is incorrect, it will immediately connect the multi-sensor array with the wireless transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com