Measurement method for volumetric weight of ore

A technology of ore and weight, which is applied in the field of measuring ore weight, can solve the problems of time-consuming, large measurement error, cumbersome operation, etc., and achieve the effect of shortening test time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

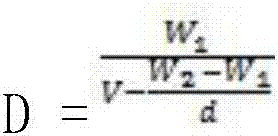

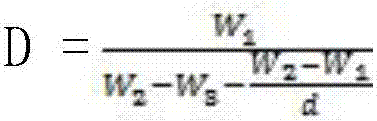

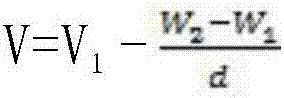

[0056] The present invention comprises the following steps: firstly correct the high-precision electronic scale through the standard body weight and the standard rock core sample, and then respectively measure the weight P of the dry ore sample in the air 1 , weight of wet ore sample in water P 2 , where the weight P 1 Weigh directly on the high-precision electronic scale, the weight P 2 The ore sample is suspended on a high-precision electronic scale and then weighed in water. According to the force analysis, the ore is affected by gravity and buoyancy in the water, and the weight of the ore can be obtained by calculation:

[0057]

[0058] The derivation process of the present invention is as follows:

[0059] The gravity of the dry ore sample in the air:

[0060] G 1 =P 1 g

[0061] The buoyancy force on the ore sample in water is:

[0062] f 浮 =ρgv

[0063] The gravity of the wet ore sample in water:

[0064] G 2 =P 2 g=P 1 g-F 浮 =P 1 g-ρgv

[0065] Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com