Inductive igniter with flameout self-locking function

An inductive, igniter technology, applied in the field of gasoline engines, can solve the problems of misstarting the gasoline engine, the gasoline engine cannot be completely shut down, etc., to avoid false start, prevent the bad igniter, and realize the effect of flameout protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the drawings and embodiments.

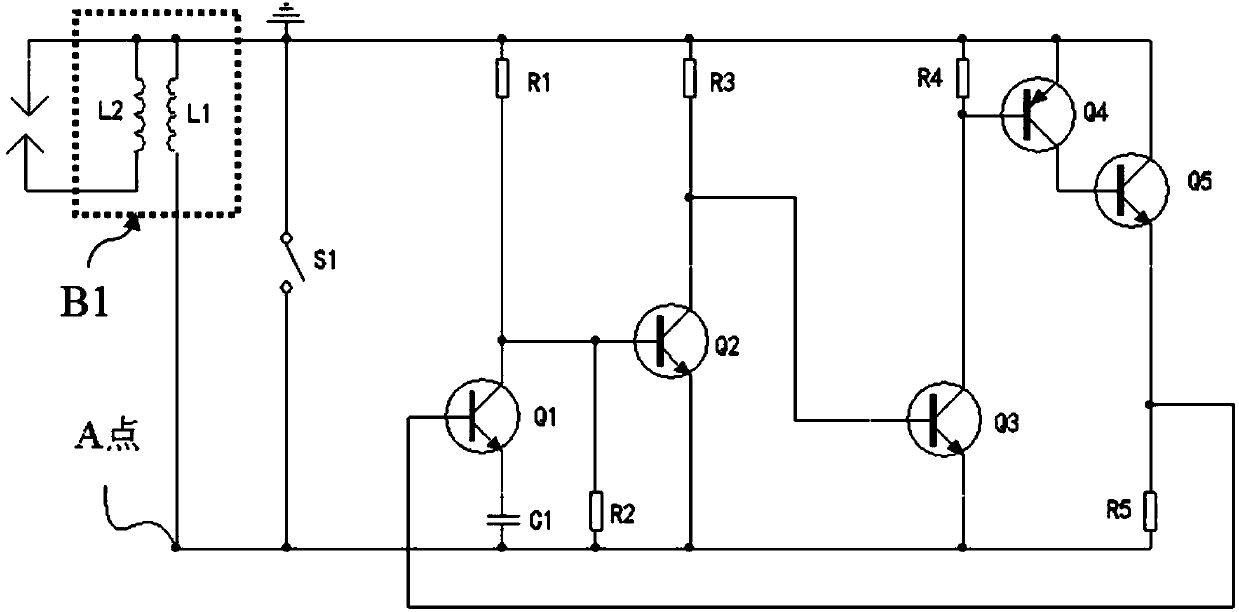

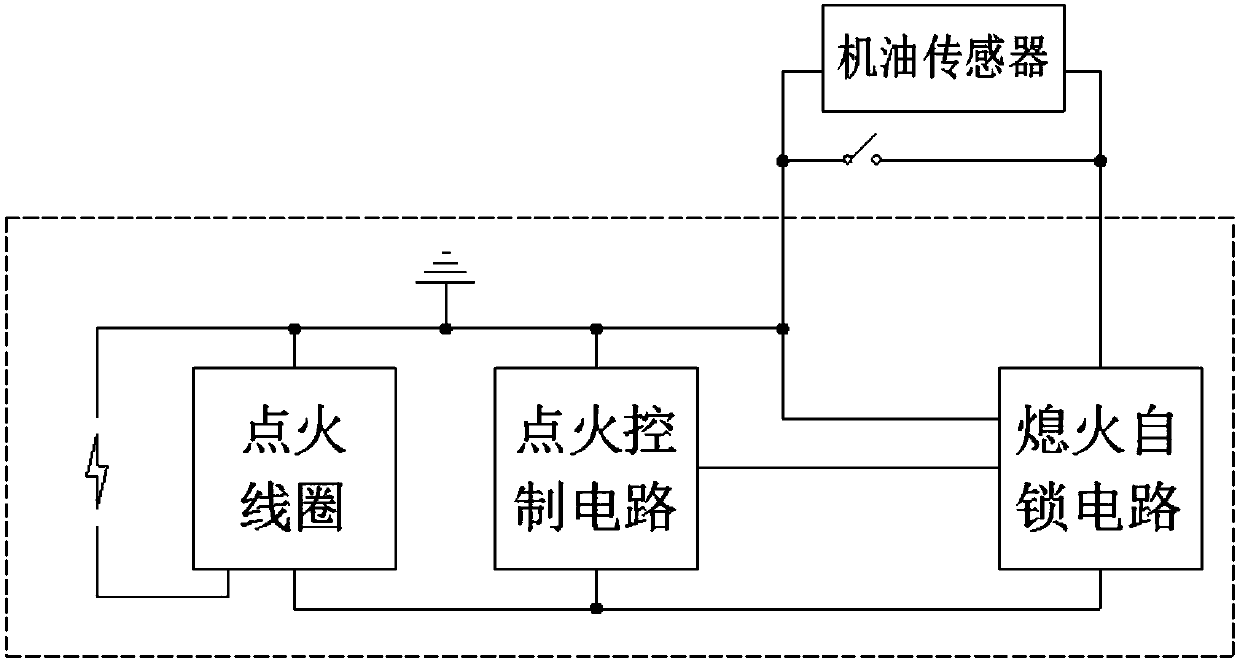

[0026] Such as Figure 4 As shown, the inductive igniter with flameout self-locking function of this embodiment includes an ignition coil B1 composed of a primary coil L1 and a secondary coil L2, and an ignition control circuit connected to the primary coil. The ignition control circuit is used to control ignition The coil generates high-voltage pulses, and further includes a flame-out self-locking circuit connected to the ignition control circuit, and the flame-out self-locking circuit is used to disable the ignition control circuit;

[0027] The ignition control circuit includes a first resistor R1, a second resistor R2, a third resistor R3, a fourth resistor R4, a fifth resistor R5, a first triode Q1, a second triode Q2, and a third triode Q3, the fourth transistor Q4, the fifth transistor Q5, and the first capacitor C1;

[0028] One end of the first resistor is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com