Fabric and application thereof

A fabric and special-shaped fiber technology, applied in the field of clothing fabrics, can solve the problems of large coverage coefficient of down jackets, affecting the comfort of down jackets, and low air permeability of down jackets, and achieve the effects of strong irregularity of pores, tight arrangement, and improved air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

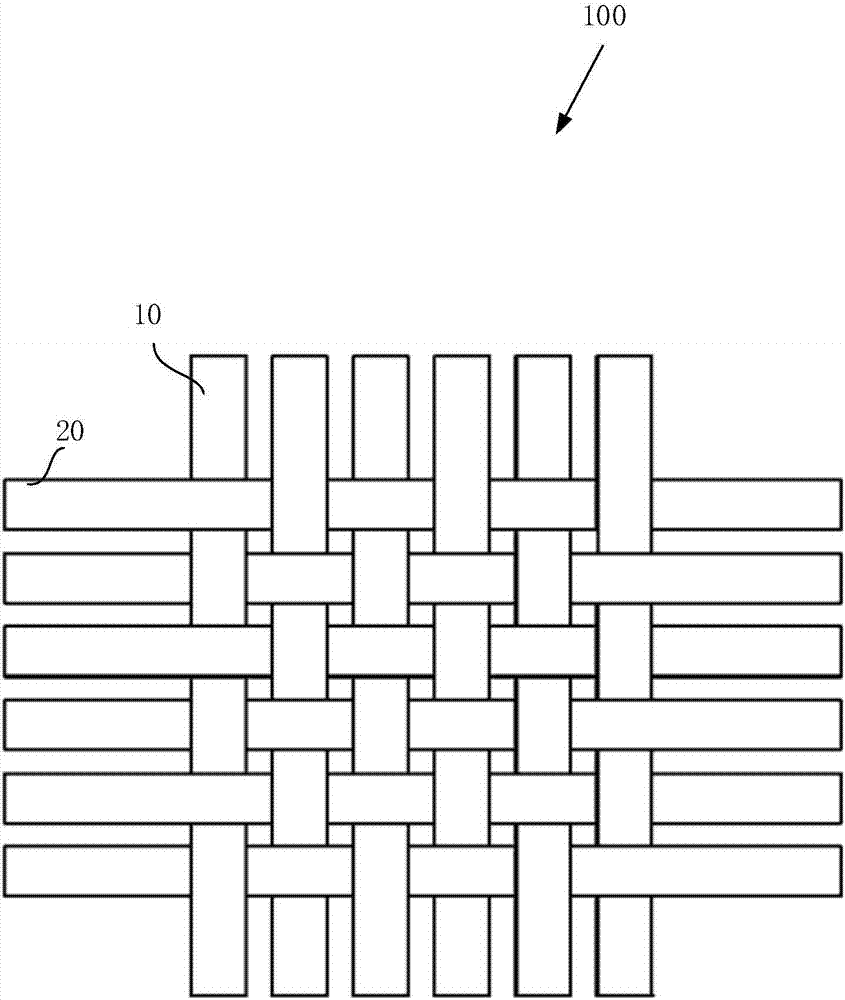

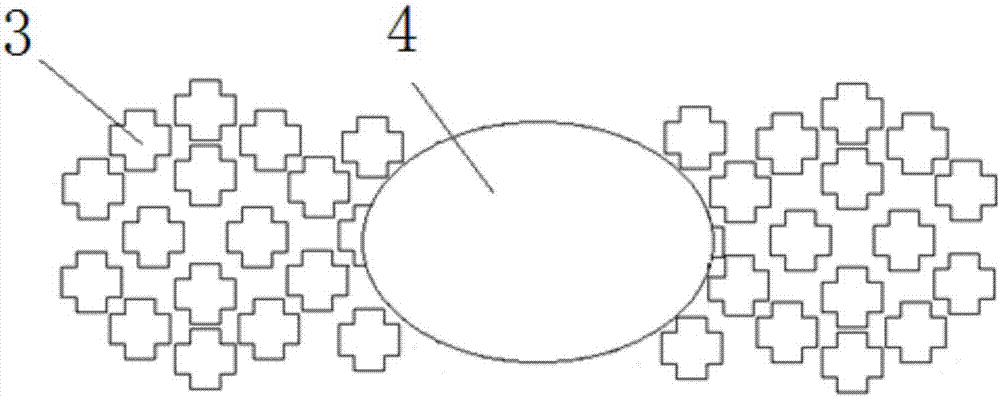

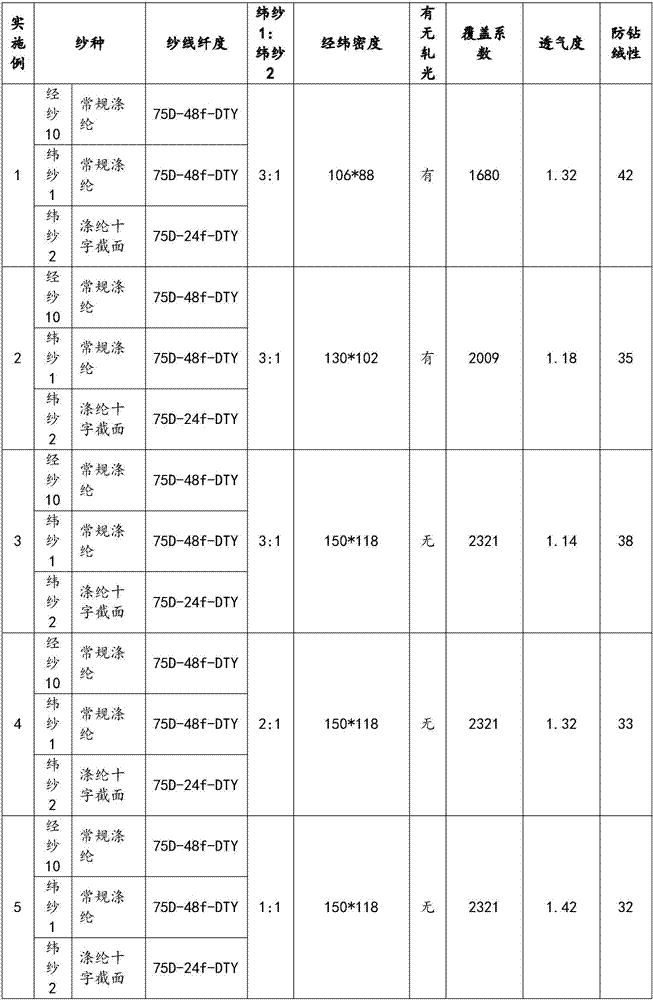

[0028] Embodiment 1 of the present invention provides a kind of fabric, such as figure 1 and figure 2 As shown, the fabric is formed by interweaving a plurality of warp yarns 10 and a plurality of weft yarns 20, wherein at least one of the warp yarns 10 and weft yarns 20 of the fabric contains a special-shaped fiber yarn 3 composed of a plurality of special-shaped fiber filaments, and the special-shaped fiber The proportion of the weight of the yarn 3 in the fabric is a preset ratio.

[0029] Wherein, when the shaped fiber yarn 3 and the non-shaped fiber yarn 4 in the fabric are interlaced, the cover factor of the fabric is greater than or equal to 1600.

[0030] In summary, since the warp yarn 10 and the weft yarn 20 of the fabric are partially shaped fiber yarns 3, and the weight of the shaped fiber yarns 3 has a certain proportion in the fabric, and because the shaped fiber yarns 3 are composed of multiple sections of Special-shaped special-shaped fiber filaments are bun...

Embodiment 2

[0039] Embodiment 2 of the present invention provides a kind of fabric, and the specification, structure, weaving process, processing technology of the fabric provided in Embodiment 2 of the present invention are roughly the same as Embodiment 1 of the present invention, and its difference is that in this invention In Example 2, when the fabric is a gray cloth, its warp density at design time is 122 threads / inch, and the weft thread density is 88 threads / inch, and after it is processed into a finished product from the gray cloth, its warp thread density is 130 threads / inch. / inch, the weft density is 102 / inch, and the cover factor is 2009. And, according to the method that adopts in above-mentioned embodiment 1, it is measured that its air permeability is 1.18cc / cm 2 , and its anti-drilling property is 35.

[0040] It can be seen that when the cover factor of the fabric becomes larger, the downproof property of the fabric increases gradually, but the air permeability decrease...

Embodiment 3

[0042] Embodiment 3 of the present invention provides a kind of fabric, and the specification, structure, weaving process, processing technology of the fabric provided in Embodiment 3 of the present invention are roughly the same as Embodiment 1 of the present invention, and its difference is that in this invention When the fabric in the embodiment is gray cloth, its warp density at the time of design is 141 threads / inch, and the weft thread density is 102 threads / inch, and after it is processed into a finished product from gray cloth, its warp thread density is 150 threads / inch , the weft density is 118 / inch, and the cover factor is 2321. And, according to the JISL1096:2010 standard, its air permeability is 1.14cc / cm 2 , and according to the GB / T14272 Appendix E standard, its anti-drilling property is 38.

[0043] In addition, it should be noted that the fabric in this embodiment is not processed by calendering process in the process of processing it from gray cloth to finis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com