Aluminum substrate printed circuit board chemical nickel palladium gold process

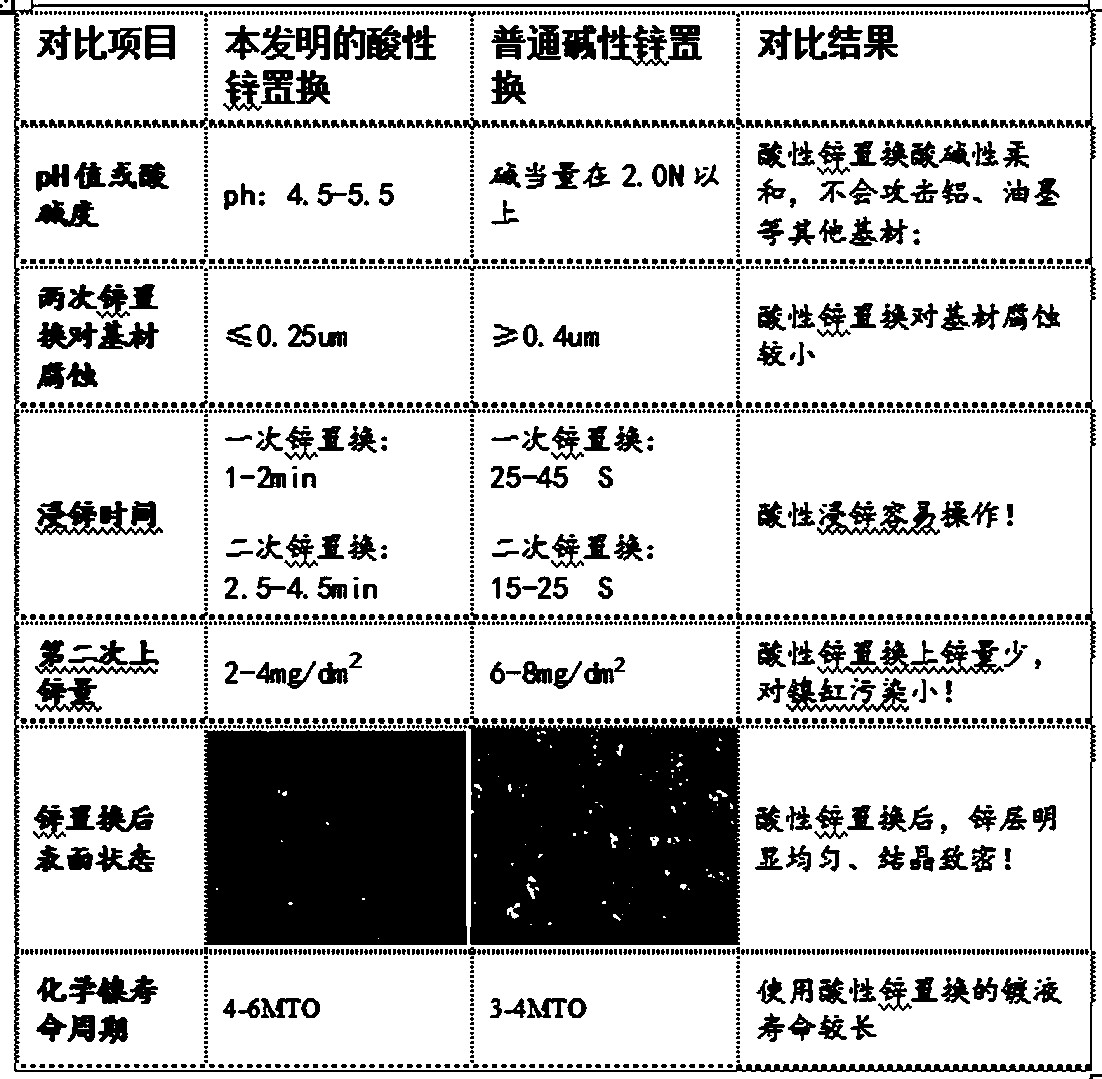

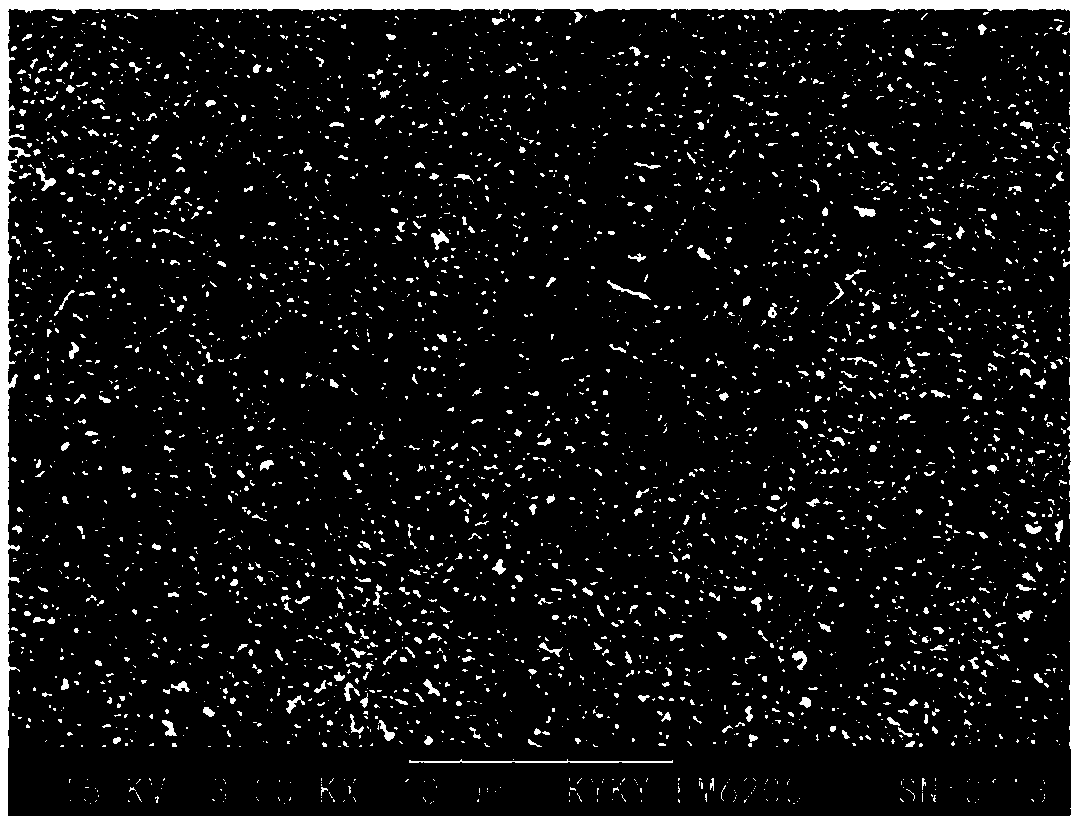

A technology for printed circuit boards and aluminum substrates, applied in metal material coating technology, liquid chemical plating, coatings, etc., can solve the problem of rough and loose zinc replacement layer, short service life of nickel plating bath, and large attack on aluminum substrates and other issues to achieve the effect of easy operation, wide operation window and small attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: The following are examples according to the process steps:

[0051] 1> Cleaning: Commercial potion

[0052] 2> Two washes

[0053] 3> 50% nitric acid soaking: 20℃, 1min

[0054] 4> Two washes

[0055] 5> One-time acid zinc dip: 30g / L zinc sulfate, 50g / L nickel sulfate, 30g / L ammonium acetate, 10g / L DTPMP (diethylene triamine pentamethylene phosphonic acid) 10g / L; 30°C, pH 5.5, 1min;

[0056] 6> Two washes

[0057] 7> 50% nitric acid soaking: 20℃, 1min

[0058] 8> Secondary acid zinc dip: zinc sulfate 30g / L, nickel sulfate 50g / L, ammonium acetate 30g / L, DTPMP (diethylene triamine pentamethylene phosphonic acid) 10g / L; 30°C, pH 5.5, 5min.

[0059] 9> Two washes

[0060] 10> Electroless nickel plating: nickel sulfate 25g / L, citric acid 20g / L, sodium hypophosphite 20g / L, lactic acid 20g / L, succinic acid 10g / L, thiourea 1mg / L, pH value adjusted to 4.5 with ammonia, The temperature is 89°C, 25min.

[0061] 11> Two washes

[0062] 12> Electroless palladium plating: palladium sulfat...

example 2

[0066] Example 2: The following examples follow the process steps:

[0067] 1> Cleaning: Commercial potion

[0068] 2> Two washes

[0069] 3> 50% nitric acid soaking: 20℃, 30S

[0070] 4> Two washes

[0071] 5> One-time acid zinc dip: 45g / L zinc sulfate, 30g / L nickel sulfate, 10g / L ammonium acetate, 20g / L DTPMP (diethylene triamine pentamethylene phosphonic acid) 20g / L; 25°C, pH 5.2, 2min;

[0072] 6> Two washes

[0073] 7> 50% nitric acid soaking: 20℃, 1min

[0074] 8> Secondary acid zinc dip: 45g / L zinc sulfate, 30g / L nickel sulfate, 10g / L ammonium acetate, 20g / L DTPMP (diethylene triamine pentamethylene phosphonic acid) 20g / L; 25℃, pH value 5.2, 3min;

[0075] 9> Two washes

[0076] 10> Electroless nickel plating: nickel sulfate 20g / L, citric acid 20g / L, sodium hypophosphite 30g / L, lactic acid 15g / L, succinic acid 15g / L, thiourea 3mg / L, pH value adjusted to 4.5 with ammonia, The temperature is 70°C, 25min.

[0077] 11> Two washes

[0078] 12> Electroless palladium plating: palladium sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com