Roller brush and production technology thereof

A production process and roller brush technology, applied in the direction of manufacturing tools, metal processing equipment, wheels with flexible working parts, etc. Tight and compact, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

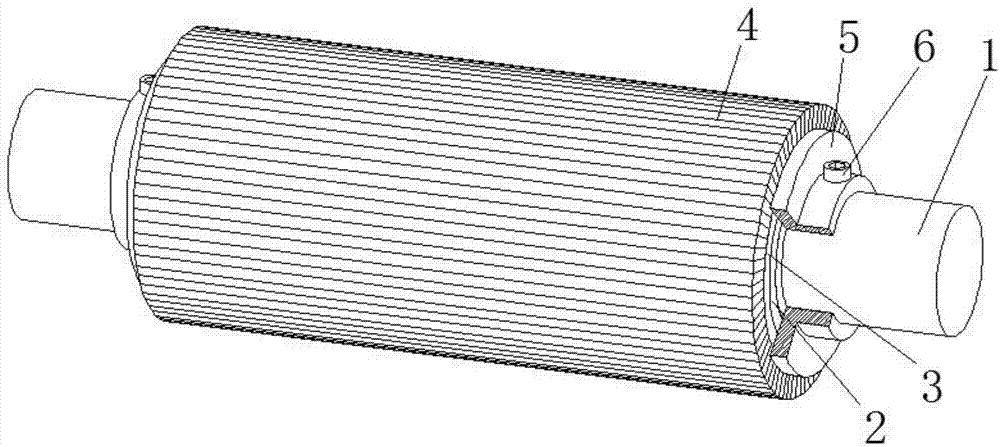

[0024] Referring to the accompanying drawings, a roller brush includes a roller 2 and bristles 4. The roller 2 is a hollow cylindrical structure, and its two ends are fixedly connected with a connecting shaft 1. Made of plastic material, the circumferential surface of the roller 2 is provided with a number of connection screw holes, the hair-planting layer 3 is provided with connection holes corresponding to the screw holes, the hair-planting layer 3 is fixedly connected with the roller 2 by screws, and the roller 2 The outer peripheral surface of the shaft is provided with a number of embedding grooves parallel to the axial direction, and the inner peripheral surface of the hair-planting layer 3 is provided with protrusions corresponding to the embedding grooves, and the hair-planting layer 3 cooperates with the roller 2 Fixed connection, bristles 4 are connected to the outside of the flocking layer 3, the bristles 4 are strip-shaped sheet structures, the bristles 4 are made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com