An improved sleeve expansion device

An improved and sleeve-expanding technology, applied in the direction of expanding the mandrel, can solve the problems of complex structure, difficult operation, and small expansion and contraction of the expansion sleeve, and achieve the effects of reducing production costs, improving production efficiency, and increasing expansion and contraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

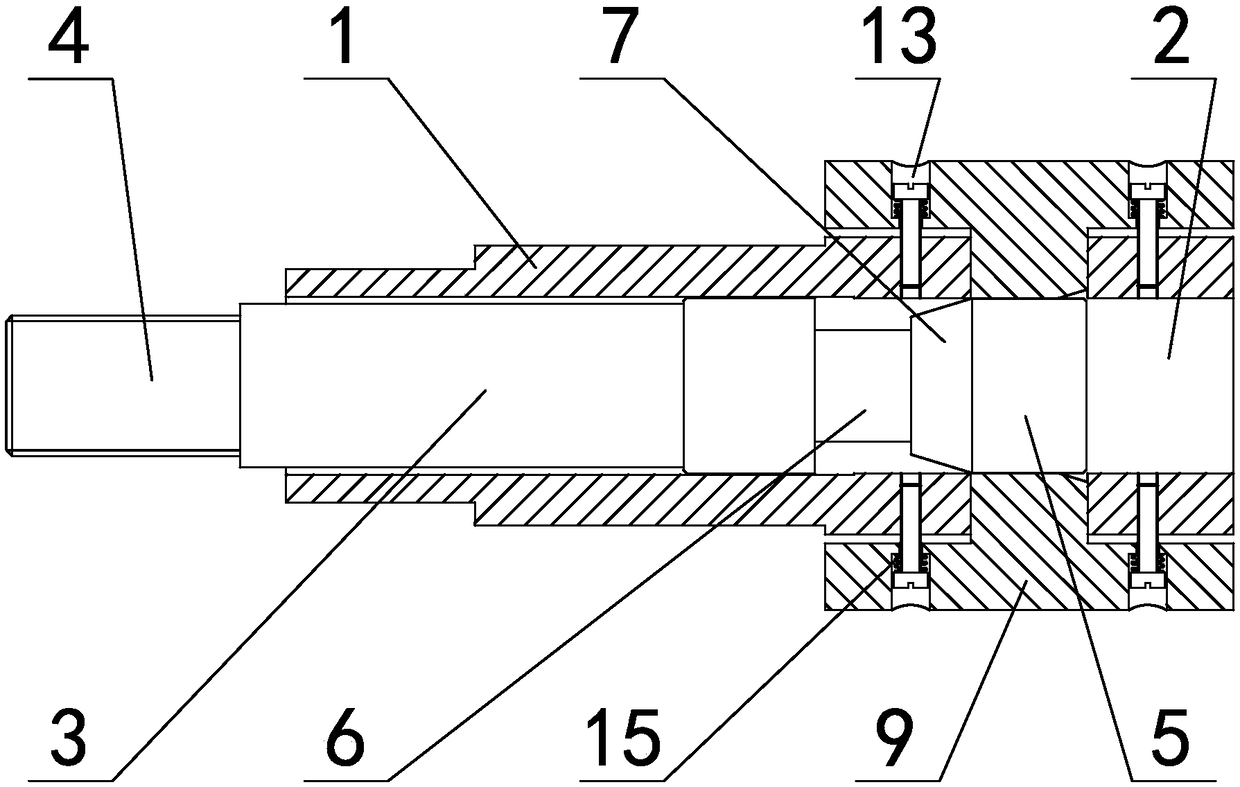

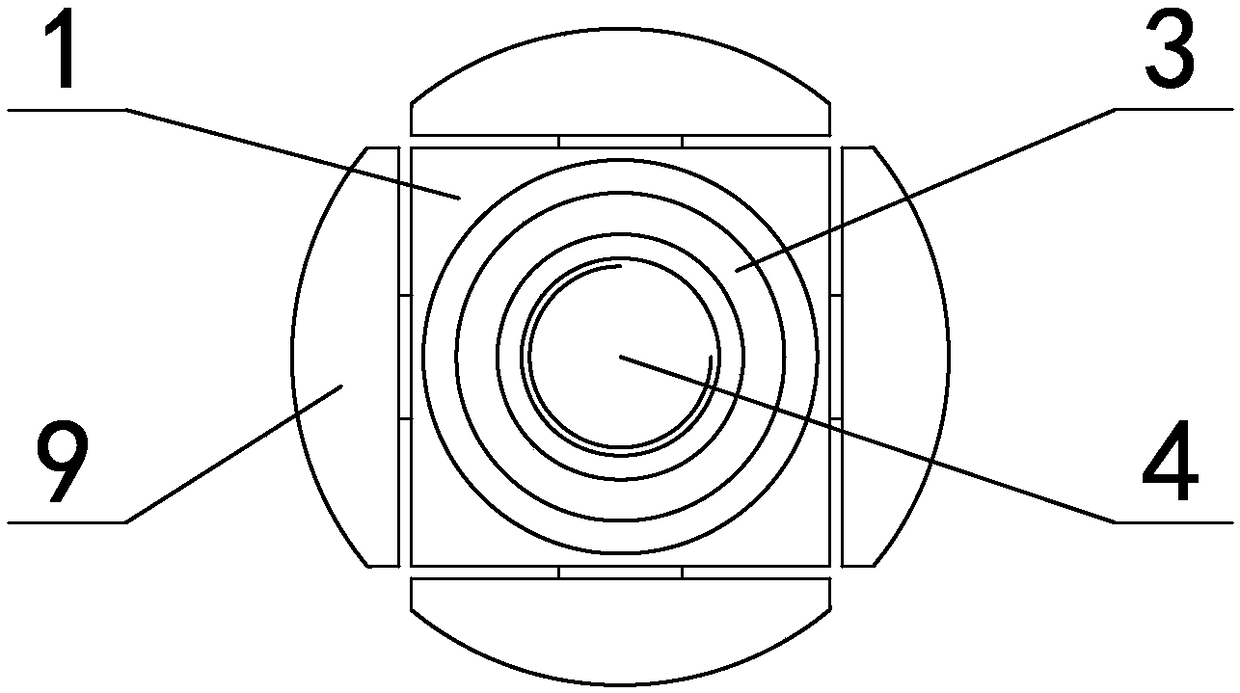

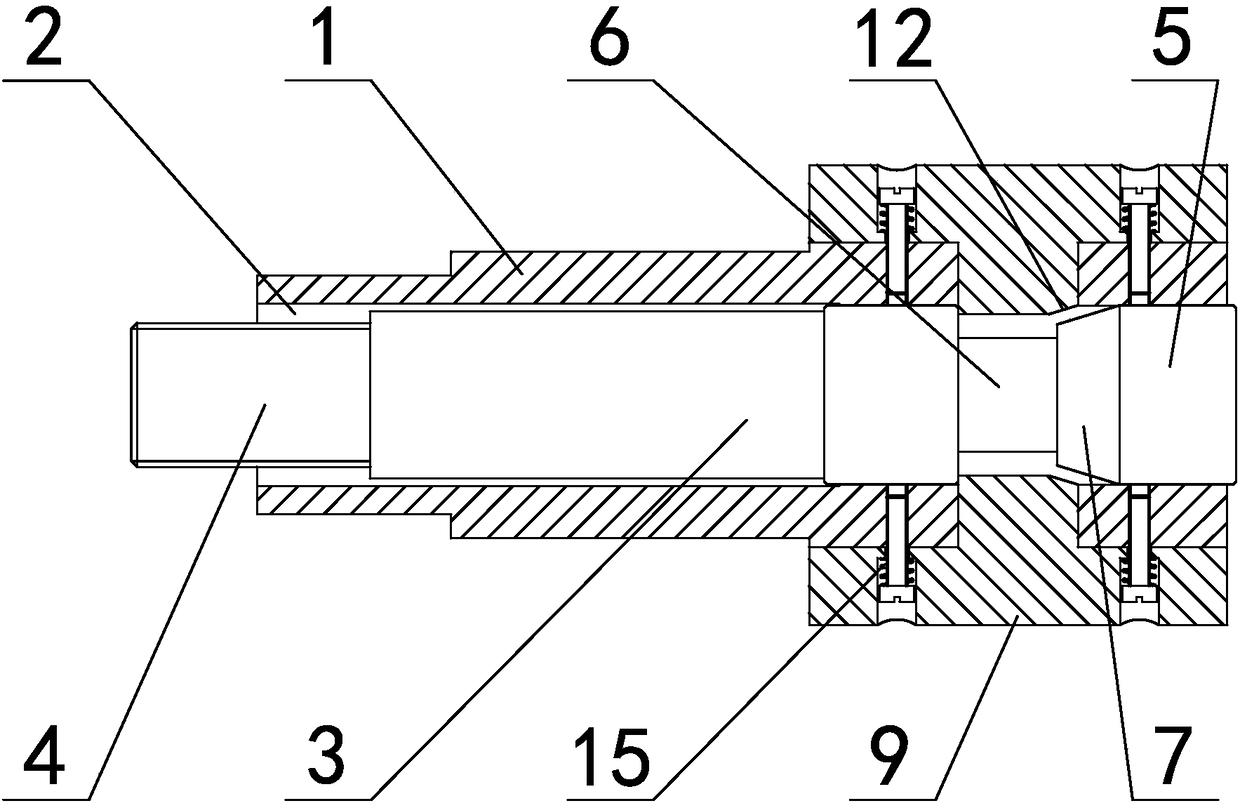

[0028] in such as figure 1 figure 2 In the shown embodiment 1, an improved expansion sleeve device is used for the processing of the motor casing, including the shaft sleeve 1 whose rear end can be fixed with the machine tool (see Figure 5 ), the center of the sleeve is provided with a shaft hole 2 (see Figure 5 Figure 6 ), the shaft hole is provided with a cylindrical telescopic shaft 3 that can move axially along the shaft hole (see Figure 7 ), the telescopic shaft includes a connecting part 4 at the rear end and an extruding part 5 at the front end, the connecting part is provided with an external thread that can be connected with the piston shaft of the telescopic cylinder; the rear side of the extruding part is provided with a necking section 6, The diameter of the necking section is smaller than the diameter of the extrusion part, and the guide tapered surface 7 is guided between the extrusion part and the necking section. A number of mounting surfaces 8 are unif...

Embodiment 2

[0031] Embodiment 2 A fine-tuning hole 17 is provided in the center of the front end of the extruding part of the telescopic shaft (see Figure 10 ), the fine-tuning hole is a threaded hole, the depth of the fine-tuning hole is greater than the axial length of the extruded part, the outer wall of the fine-tuning hole is provided with radial through-slots 18, the number of radial through-slots is consistent with the number of mounting surfaces and its The center plane is on the symmetrical center plane of two adjacent mounting surfaces (there are four radial through slots in this embodiment and the center plane is on the same radial plane as the edge of the positive prism), and there are fine-tuning bolts in the fine-tuning hole 19. There is a lock nut 20 between the fine-tuning bolt and the front end of the extrusion part (see Figure 11 ), and the rest are the same as in Example 1.

[0032] The shaft sleeve of the present invention is fixed on the chuck of the machine tool. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com