A piston type high pressure expansion joint

A piston type, expansion joint technology, applied in the direction of adjustable connection, through components, expansion compensation devices for pipelines, etc., can solve problems such as small pressure bearing capacity, inability to withstand high pressure, and diameter restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention is described with reference to the drawings and specific embodiments.

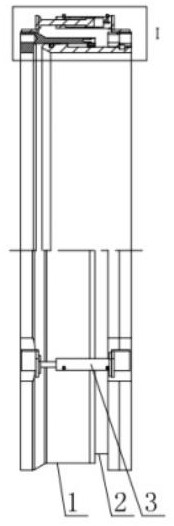

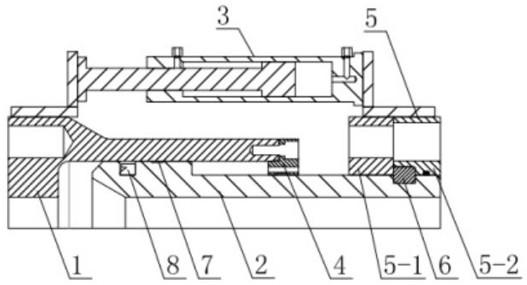

[0019] Such as Figure 1-2 As shown, a piston-type high-pressure expansion joint mainly includes a piston outer casing 1, a piston inner body 2, 3 double-acting oil cylinders 3, a limit stop flange 4, a key-type combined flange 5, a key 6, Sliding support ring 7 and high pressure seal 8. The piston outer casing 1 includes two sections of the upstream casing flange and the downstream casing; the piston inner body 2 is assembled inside the piston outer casing 1; the stop flange 4 is connected to the piston The downstream end of the outer casing 1; the keyed combination flange 5 is assembled on the outside of the piston inner body 2 and is located downstream of the limit stop flange 4; the keyed combined flange 5 is blocked by the keyed upstream The ring 5-1 is composed of the downstream flange 5-2 of the card key. During installation, the upstream retaining ring 5-1 of the card key is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com