Hot Extrusion Process of Nickel-based Alloy Rods

A nickel-based alloy, hot extrusion technology, applied in the field of metallurgy, can solve the problems of lack of accuracy, high experience value requirements, boring cars, etc., to reduce workload and cost waste, reduce experience requirements, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the hot-extruded nickel-based alloy rod has the following mass percentage distribution of main components: Ni base, 22% Cr, 12% Co, 9% Mo, 1.2% Al, 0.44% Ti.

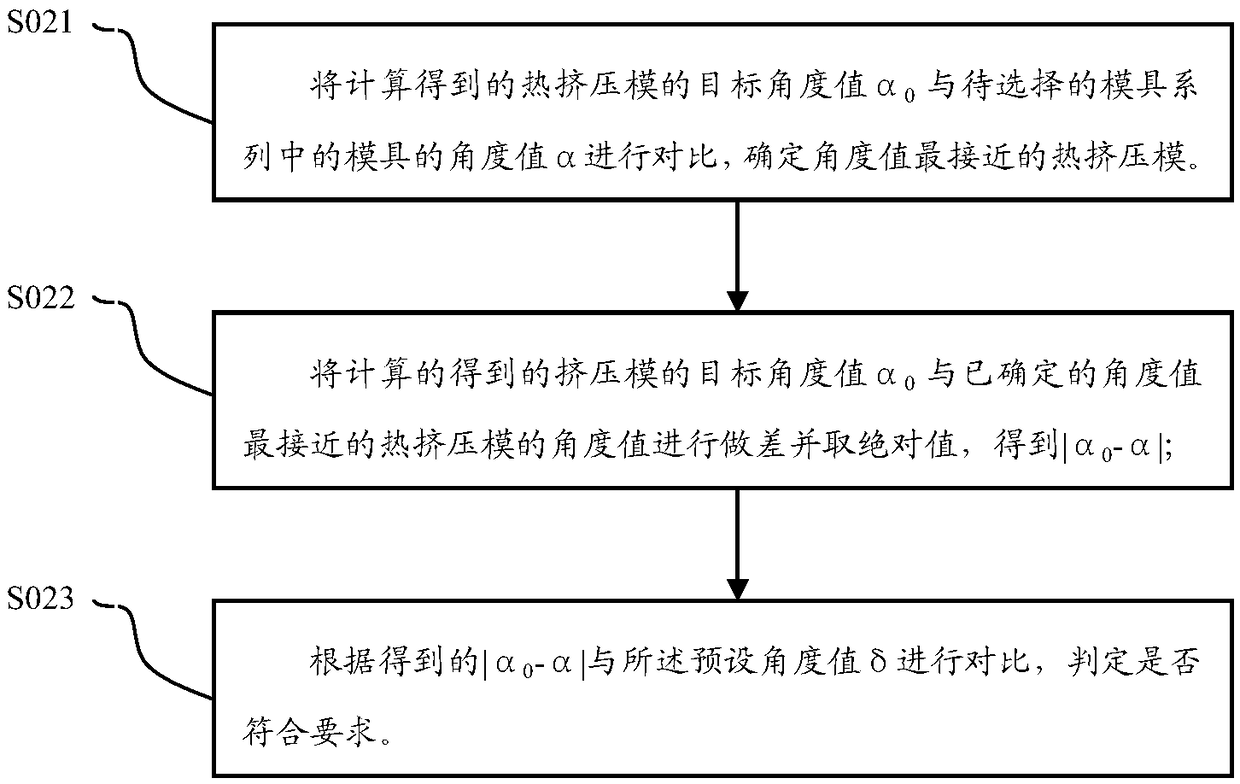

[0036] S01), calculate the target angle value α of the hot extrusion die according to the following formula 0 , the formula is:

[0037]

[0038] Among them, π is the circumference ratio, the value is 3.14; P is the extrusion ratio; V is the extrusion exit velocity of the hot extrusion die, the unit is m / s; Q is the dynamic recrystallization activation energy of the nickel-based alloy, and its value can be found in the literature Obtained from the query in KJ / mol; T is the thermodynamic temperature of hot extrusion, and the unit is K.

[0039] In this embodiment, the dynamic recrystallization activation energy of the nickel-based alloy is 549KJ / mol. The extrusion ratio is 5, the extrusion speed is 3m / s, and the extrusion temperature is 1220°C. Put the known parameters into the above form...

Embodiment 2

[0053] In this embodiment, the mass percentage ratio of the main components of the hot-extruded nickel-based alloy rod is:

[0054] Ni base, 22% Cr, 9% Mo, 5% Nb, 0.2% Ti.

[0055] S01), calculate the target angle value α of the hot extrusion die according to the following formula 0 , the formula is:

[0056]

[0057] Among them, π is the circumference ratio, the value is 3.14; P is the extrusion ratio; V is the extrusion exit velocity of the hot extrusion die, the unit is m / s; Q is the dynamic recrystallization activation energy of the nickel-based alloy, and its value can be found in the literature Obtained from the query in KJ / mol; T is the thermodynamic temperature of hot extrusion, and the unit is K.

[0058] In this embodiment, the dynamic recrystallization activation energy of the nickel-based alloy is 522KJ / mol. The extrusion ratio is 4, the extrusion speed is 4m / s, and the extrusion temperature is 1220°C. Put the known parameters into the above formula to get: ...

Embodiment 3

[0072] In this embodiment, the mass percentage ratio of the main components of the hot-extruded nickel-based alloy rod is:

[0073] Ni base, 25% Cr, 20% Co, 0.5% Mo, 1.5% Nb, 1.3% Ti, 1.3% Al.

[0074] S01), calculate the target angle value α of the hot extrusion die according to the following formula 0 , the formula is:

[0075]

[0076] Among them, π is the circumference ratio, the value is 3.14; P is the extrusion ratio; V is the extrusion exit velocity of the hot extrusion die, the unit is m / s; Q is the dynamic recrystallization activation energy of the nickel-based alloy, and its value can be found in the literature Obtained from the query in KJ / mol; T is the thermodynamic temperature of hot extrusion, and the unit is K.

[0077] In this embodiment, the dynamic recrystallization activation energy of the nickel-based alloy is 537KJ / mol. The extrusion ratio is 5, the extrusion speed is 4m / s, and the extrusion temperature is 1180°C. Put the known parameters into the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com