Prediction method for sound insulation performance of car front wall

A prediction method and technology of acoustic performance, which is applied to the analysis of solids, instruments, and materials using sonic/ultrasonic/infrasonic waves. The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose of the invention, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

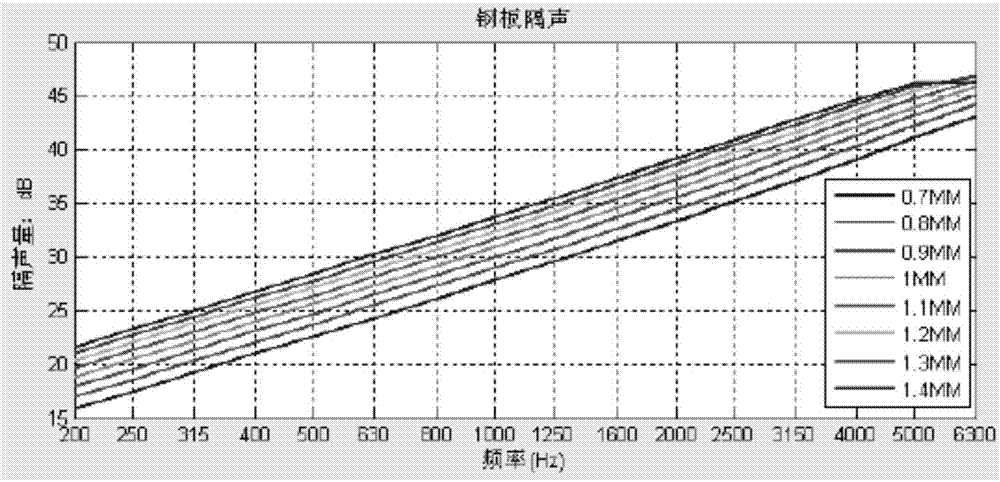

[0023] First, the theoretical basis of the present invention is introduced. The present invention uses the reverberation chamber-anechoic chamber method to predict the sound insulation of the front wall of the automobile. The test facilities used in the reverberation chamber-anechoic chamber method include a standard reverberation chamber and a standard full anechoic chamber built adjacently. Install the test part. The reverberation room is used as the test sounding room, and the full elimination room is used as the test receiving room. The sound waves randomly incident on the surface of the specimen in the reverberation chamber cause the specimen to vibrate and radiate sound energy to the full ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com