Method for rapidly determining reaction performance of dissolving pulp

A reaction performance and rapid measurement technology, which is applied in the field of pulp and paper making, can solve the problems that the measurement process is greatly affected by the environment, the measurement cycle is long, and the measurement process is cumbersome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

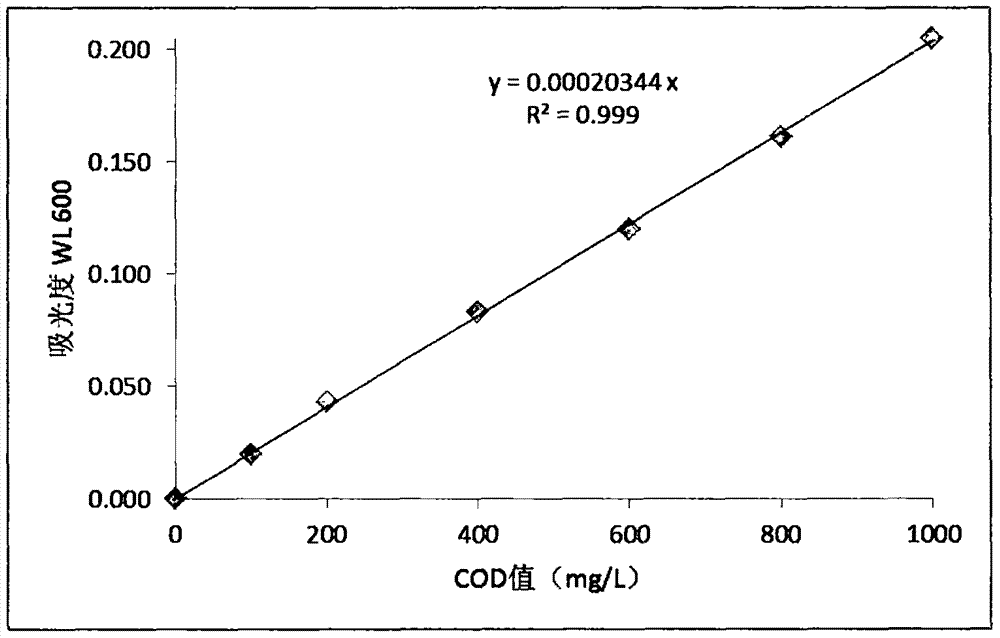

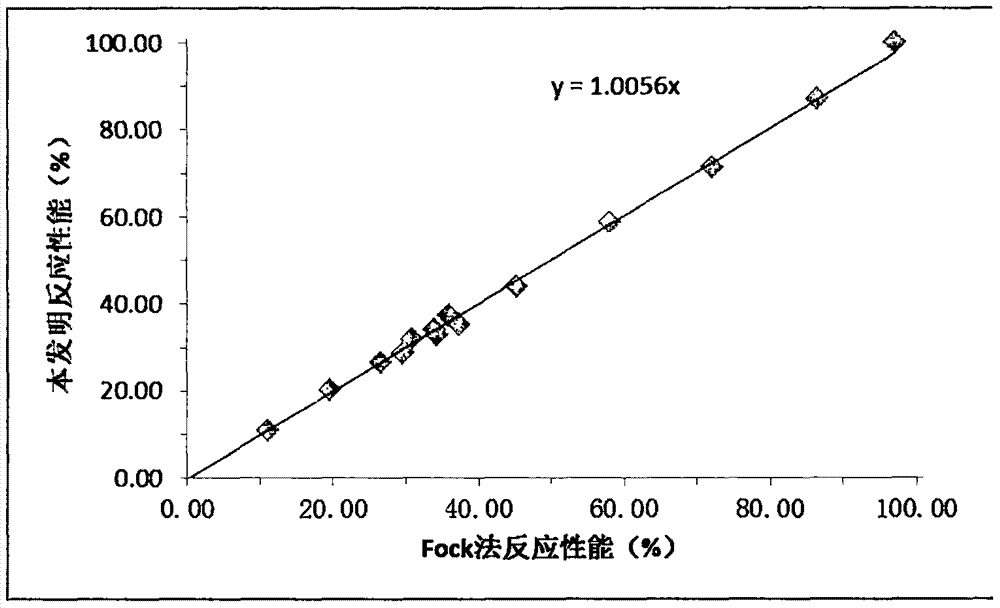

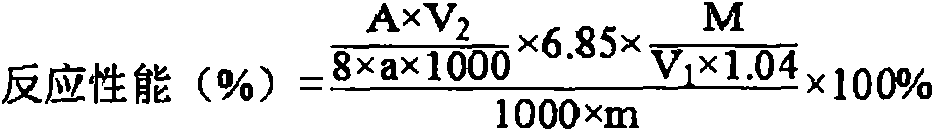

[0023] Taking the reaction performance measurement of some dissolving pulp samples as an example below, the embodiment of the present invention is described in further detail:

[0024] 1 Preparation of test reagents

[0025] a) Silver sulfate sulfuric acid solution: Dissolve 1g of silver sulfate solid in 100ml of concentrated sulfuric acid (ρ=1.84g / ml) to prepare a silver sulfate solution with a concentration of 0.01g / ml, and place the prepared solution in a brown bottle Put it aside for 1-2 days, and use it after the silver sulfate solid is completely dissolved;

[0026] b) Mercury sulfate solution: Measure about 100ml of concentrated sulfuric acid, slowly add it into a beaker filled with about 900ml of water (conductivity<5.0μs / cm, the same below), and make a sulfuric acid aqueous solution with a concentration of about 17%wt. The solution was stirred and mixed, then cooled to room temperature for later use. Weigh 125g of mercuric sulfate solid and add it to about 500ml of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com