Winding machine for rotation type loading

A winding machine, rotary technology, applied in the direction of electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of slow transmission speed of winding machine, low winding efficiency, high defective products, etc., to reduce the use of labor force Quantity, increased productivity, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

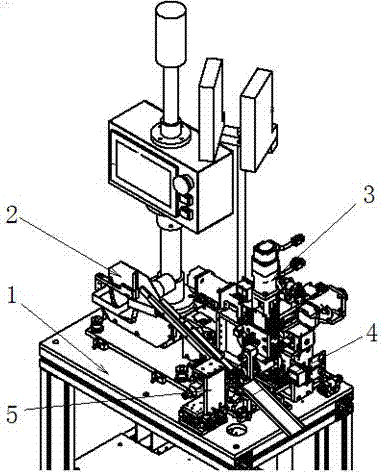

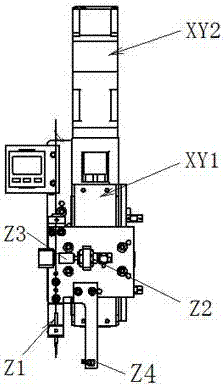

[0032] Such as Figure 1-12 As shown, a rotary feeding winding machine can regularly wind the copper wire on the magnetic core according to the requirements, including the stand 1, the feeding unit 2, the main shaft unit 3, the feeding unit 4, and the ejector unit 5 and slideway composition. And the feeding unit 2, the spindle unit 3, the feeding unit 4 and the ejector unit 5 are fixed on the bottom plate of the frame 1 as required. The control panel can count the work and switch the emergency stop button, and the alarm light prompts the working status of the winding machine with rotary feeding.

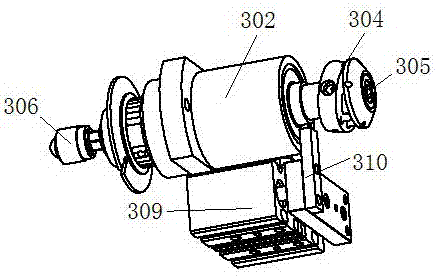

[0033] The feeding unit 2 is composed of a feeding part and a sliding part, and the feeding part is composed of a feeding motor 22 , a feeding turntable 23 , a feeding rod 25 and a feeding port 24 . The feeding motor is installed on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com