Steel wire rope rotating reel vehicle and use method thereof

A wire rope and turntable technology, which is applied in transportation and packaging, lifting equipment in mines, etc., can solve the problems of time-consuming and labor-intensive, cumbersome rope changing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

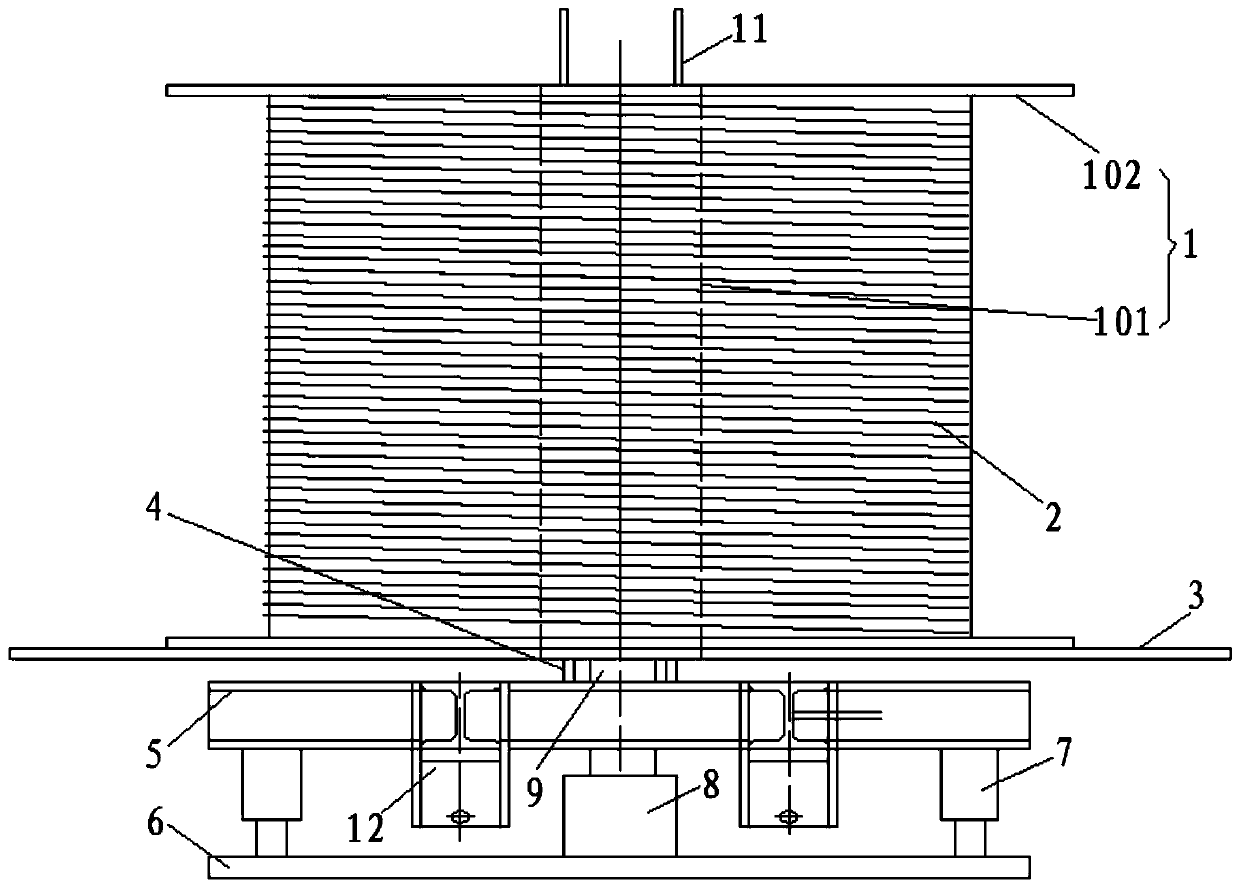

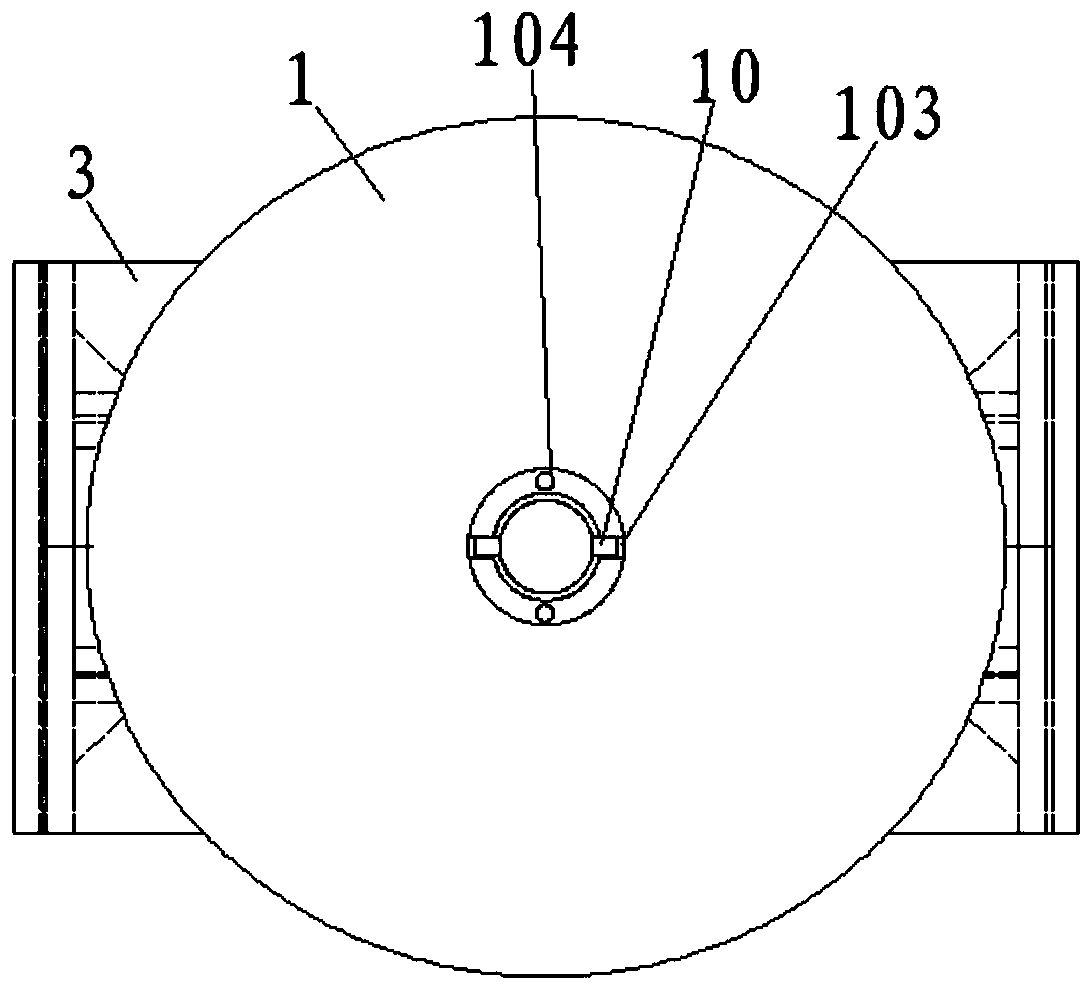

[0020] refer to Figure 1-2 Shown, the steel wire rope turntable vehicle of the present invention, it comprises:

[0021] The reel 1 includes a hollow reel 101 and a circular end plate 102. The circular end plate 102 is symmetrically arranged at both ends of the hollow reel 101, and a steel wire rope 2 is wound on the hollow reel 101, wherein the inner surface of the hollow reel 101 is parallel to the axis A limit slot 103 is provided in the direction;

[0022] The supporting plate 3, the upper surface is used to place the reel 1, the lower surface of the supporting plate 3 is connected with the upper surface of the fixed frame 5 through the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com