Mechanically controlled continuous automatic net material furling device and working method

A technology of mechanical control and working method, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problems of time-consuming and laborious operation, affecting production efficiency, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

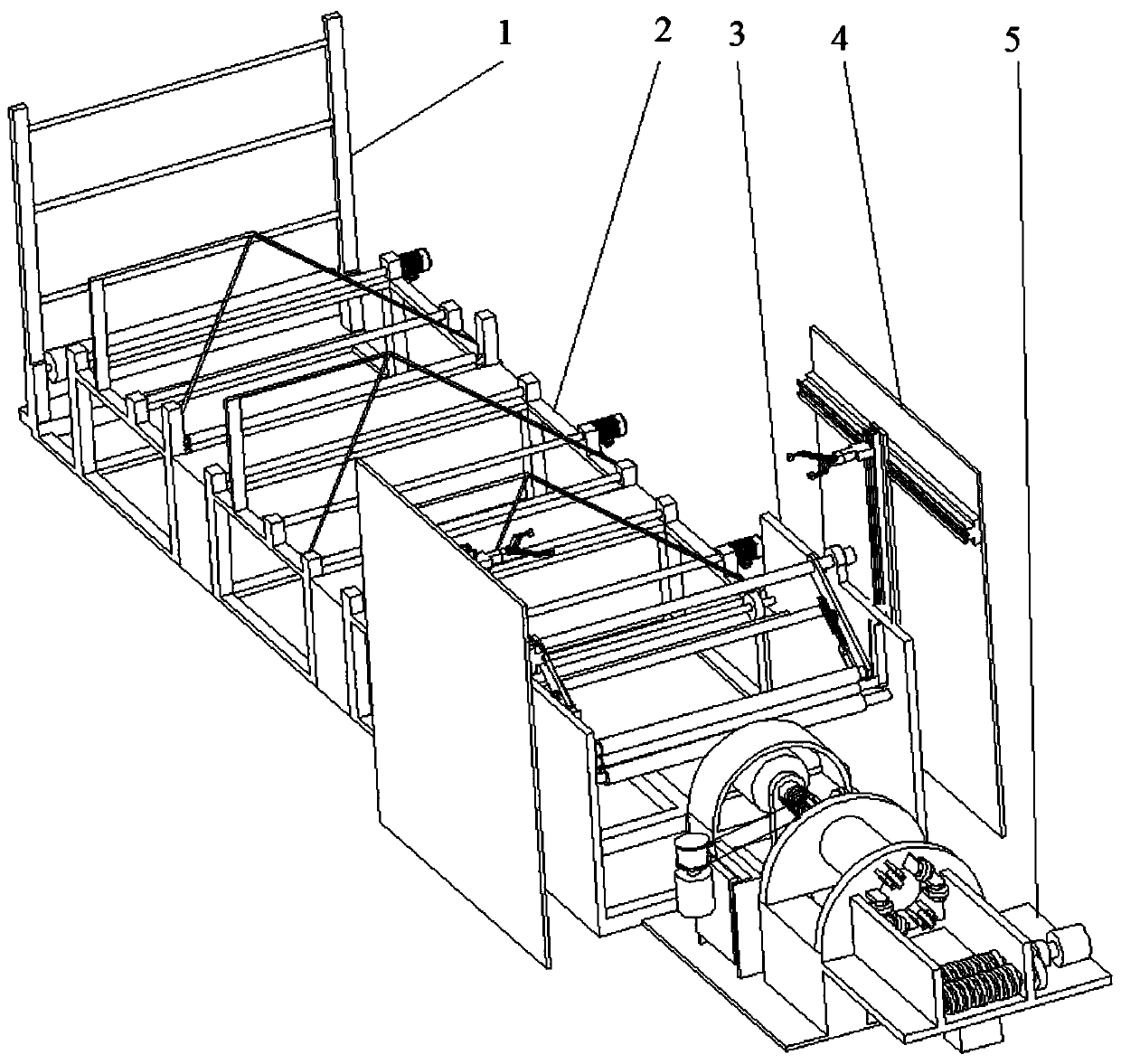

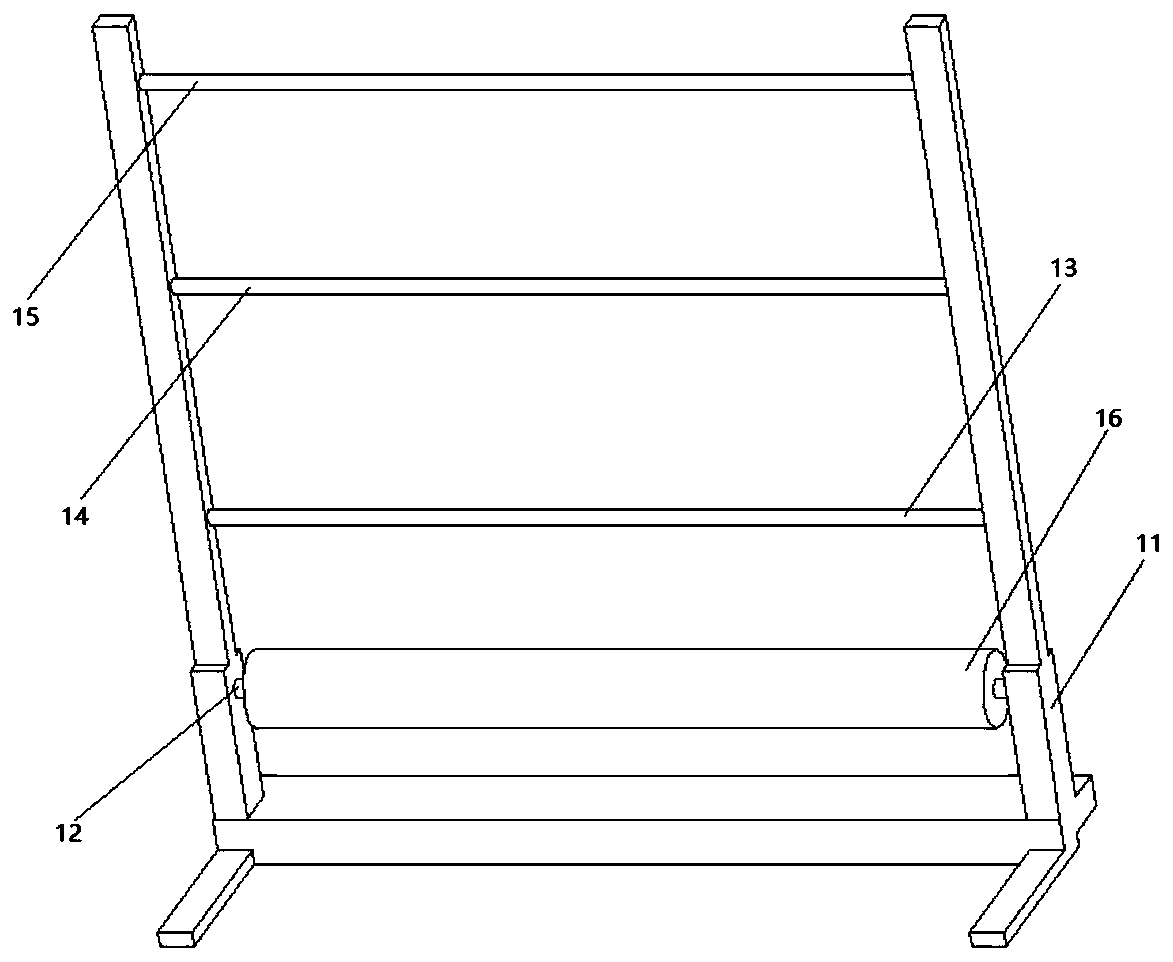

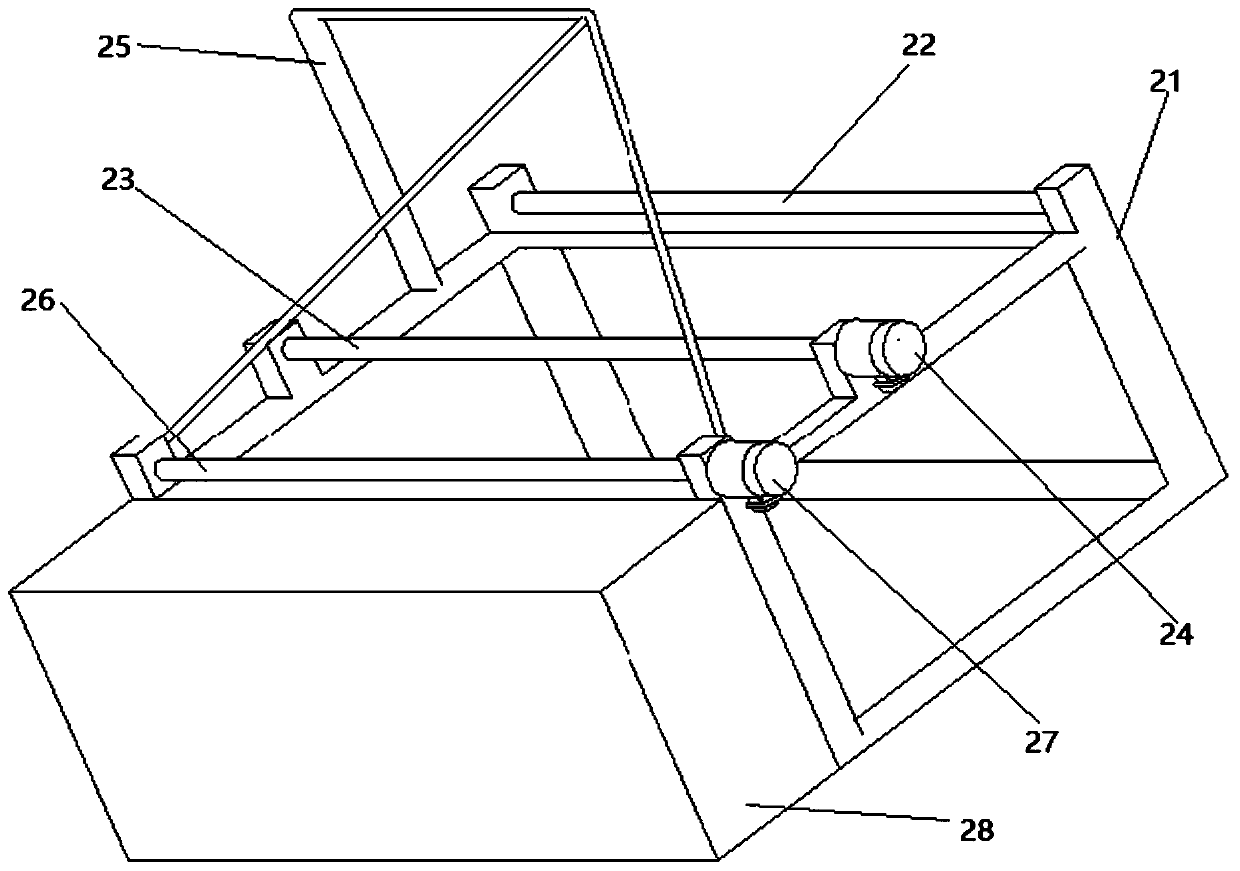

[0028] Such as figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, and 10, a mechanically controlled mesh continuous automatic folding device and working method of the present invention include: a winding device 1, a folding device 2, a rewinding device 3. Material laying device 4, continuous folding device 5; the winding device 1 is fixedly installed on the factory floor, the folding device 2 is installed on the rear side of the winding device 1, and the winding device is connected by bolts 1 is connected to the base of the folding device 2, the rewinding device 3 is installed on the rear side of the folding device 2, and rewinds the folded mesh material, and the material laying device 4 is installed on the rewinding device 2 On the upper side of the device 3, the jaws 45 of the laying device 4 move up and down and left and right to clamp the net mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com