Textile fabric winding and lifting device

A textile fabric and equipment technology, applied in the field of textile fabric rolling and lifting equipment, can solve problems such as low precision, potential safety hazards, and slow speed, and achieve efficient and fast rolling and lifting, improving efficiency and effect, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

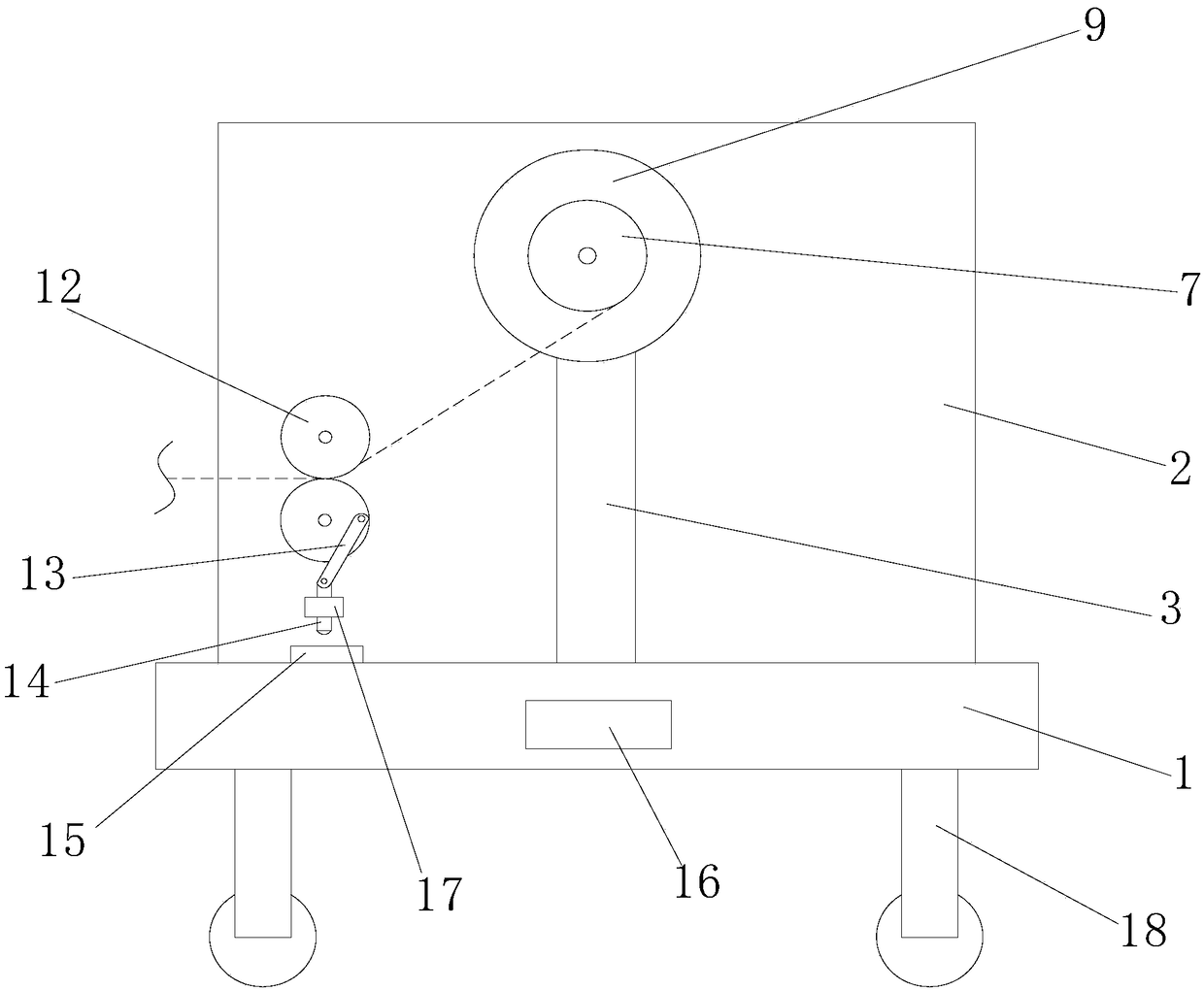

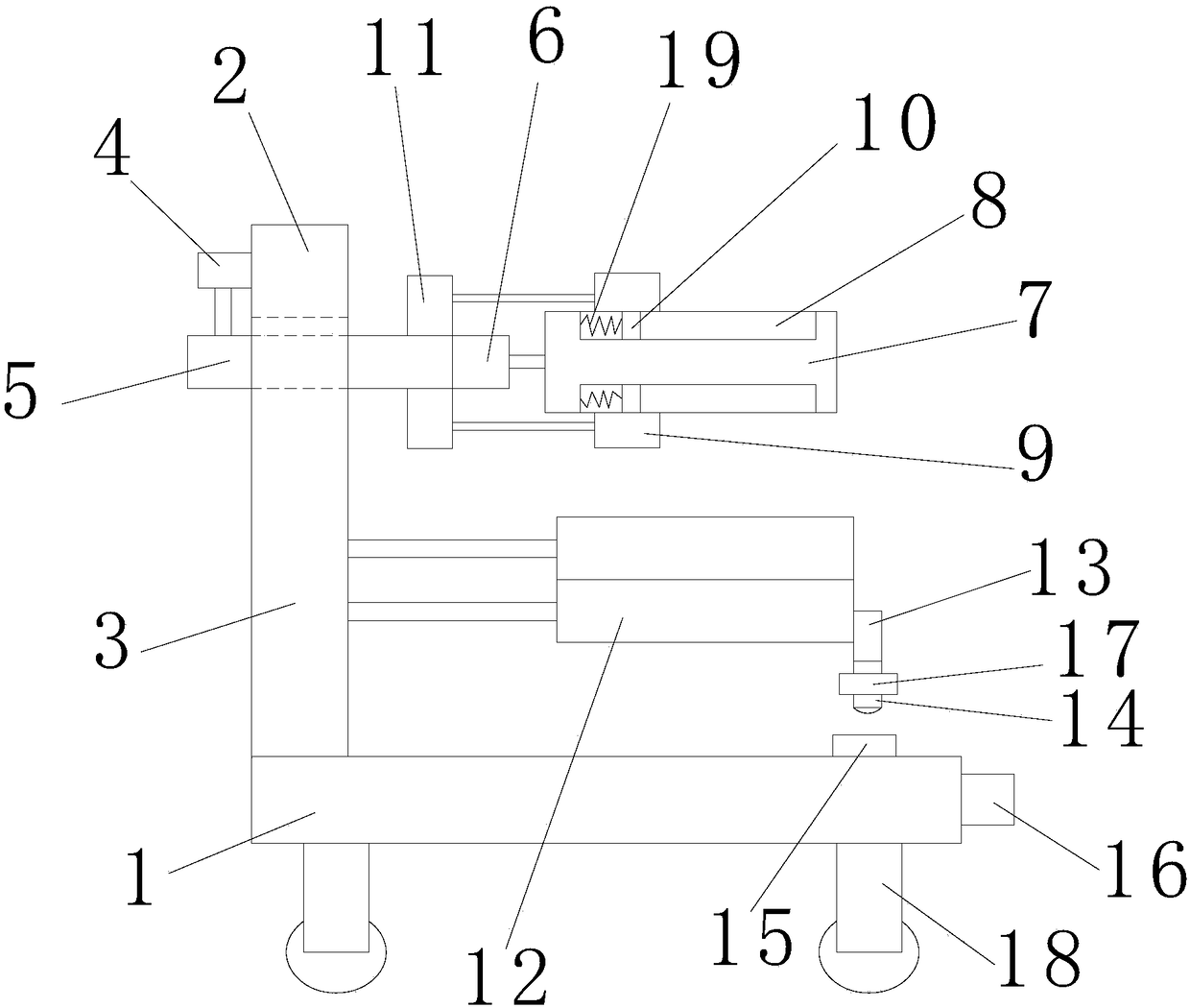

[0016] refer to figure 1 , 2 , a kind of rolling and lifting equipment for textile fabrics in the present invention, comprising a workbench 1, a frame 2, a chute 3, a lifting cylinder 4, a mounting plate 5, a motor 6, a cloth receiving roller 7, a mounting groove 8, a cloth pushing block 9, Block 10, cloth pushing cylinder 11, cloth guide roller 12, transmission rod 13, pressure rod 14, pressure sensor 15, counter 16, sleeve 17 and support leg 18, the upper part of described workbench 1 is fixedly provided with vertically The frame 2 is provided with a vertically arranged chute 3 on the frame 2, and the upper end of the frame 2 is fixedly provided with a lifting cylinder 4 whose output shaft is vertically set downward, and slides in the chute 3 A horizontally arranged mounting plate 5 is pierced, and the upper part of the mounting plate 5 is fixedly connected to the lower end of the output shaft of the lifting cylinder 4. The front end of the mounting plate 5 is fixedly provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com