A pressing machine for permanent magnet processing line

A technology of assembly line and plate pressing machine, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of reduced efficiency of permanent magnets, large demand for permanent magnets, inability to achieve continuous production, extrusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

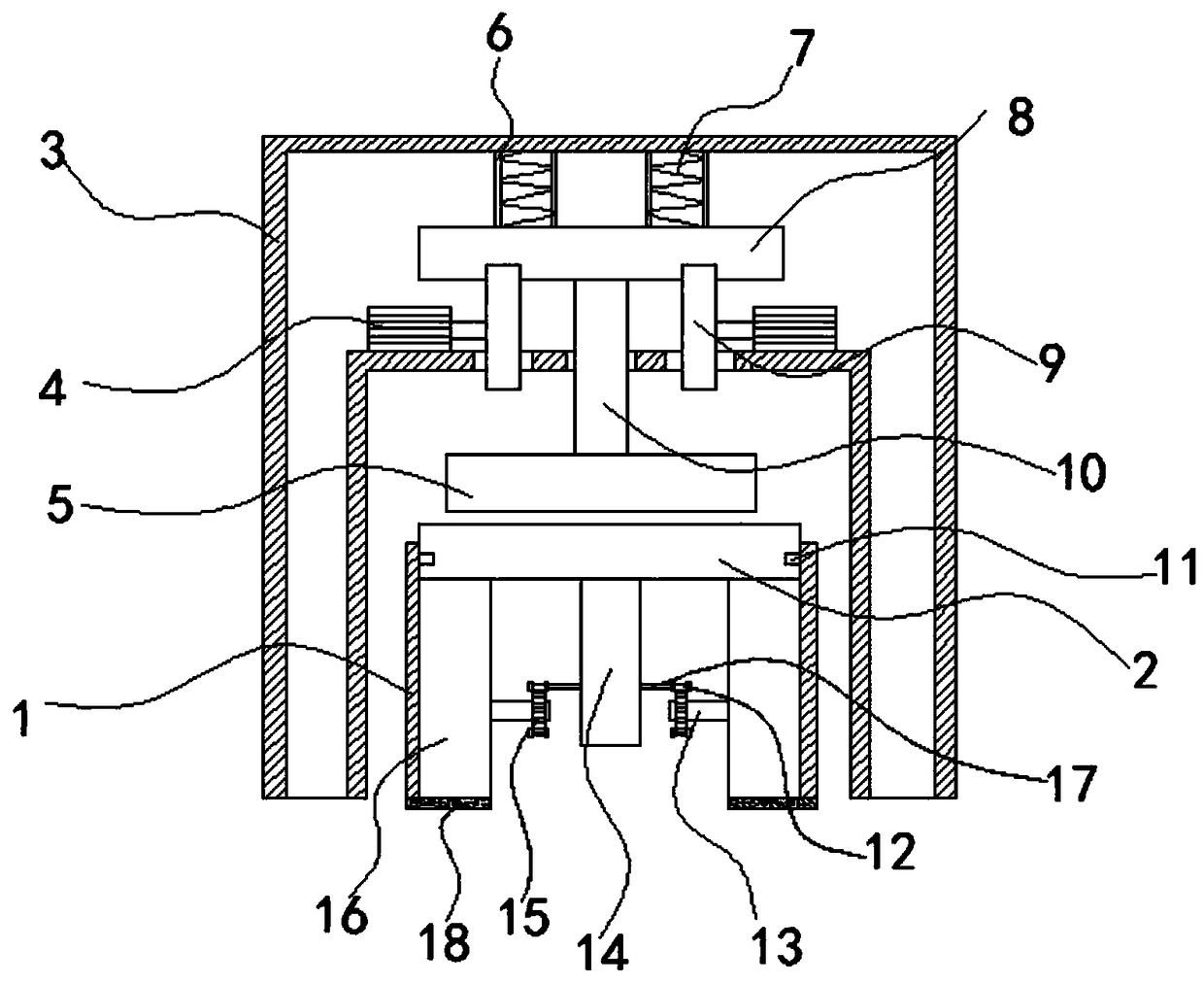

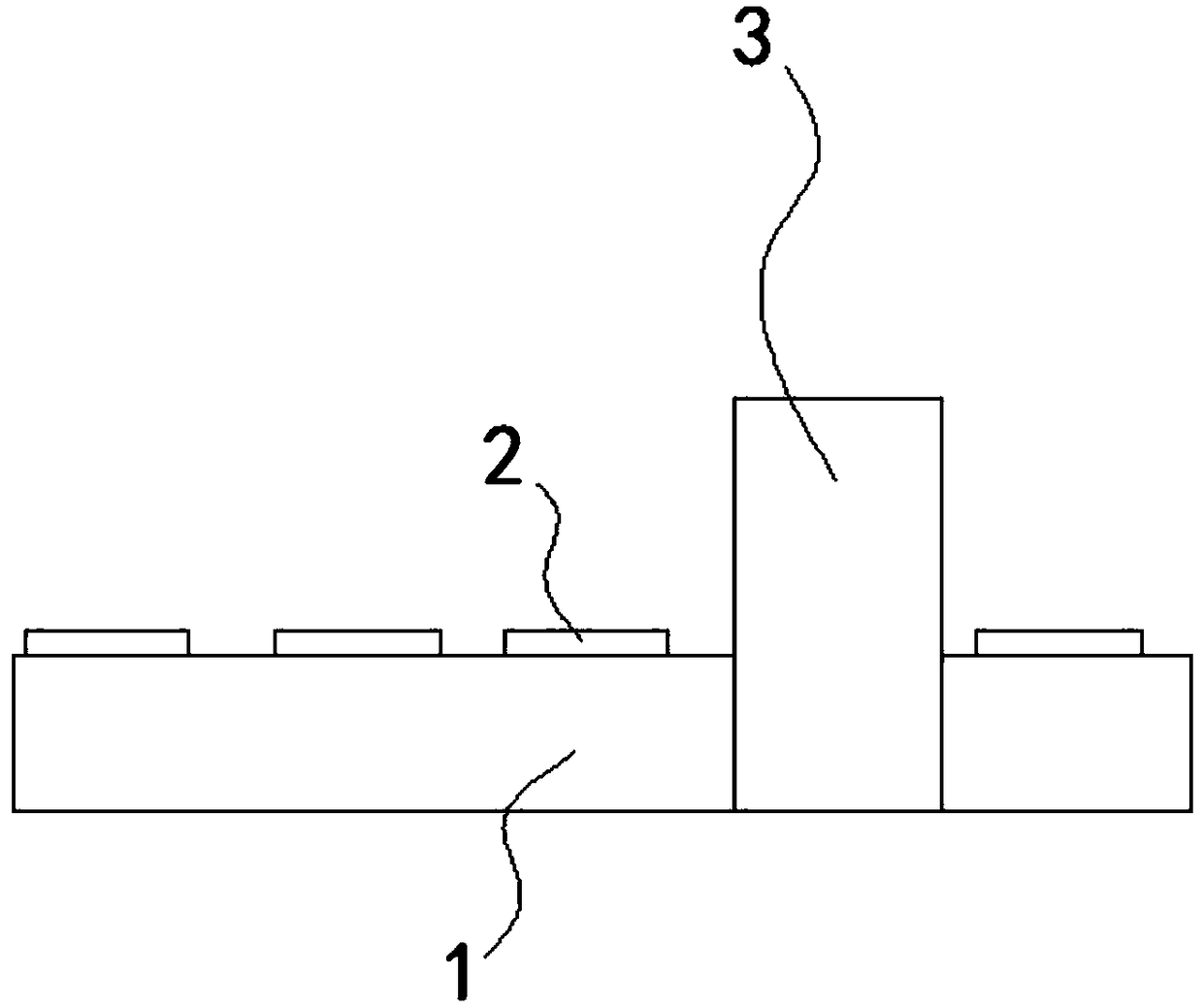

[0015] Reference Figure 1-2 , A plate pressing machine for permanent magnet processing line, including door frame 3 and two long splints 1, door frame 3 is provided with a cavity, and the cavity is symmetrically provided with a driving motor 4 and two driving motors 4 Both are fixedly connected to the inner wall of the bottom of the cavity, the output ends of the two drive motors 4 are fixedly connected with cams 9, and the two cams 9 are slidably connected with a placement plate 8. The placement plate 8 is provided with a corresponding cam 9 on the side close to the cam 9 The side of the placement plate 8 close to the cam 9 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com