Method for determining steel slag content of steel slag soil

A determination method and technology of steel slag, which is applied in the direction of chemical analysis by titration method, can solve the problem of uniformity, steel slag content inspection and other problems, and achieve the effect of ensuring the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Solution preparation:

[0033] (1) 0.1mol / L "disodium ethylenediaminetetraacetic acid (referred to as EDTA disodium) standard solution: Accurately weigh 37.226g of EDTA disodium (analytical pure) with an analytical balance, dissolve it in slightly heated carbon dioxide-free distilled water, wait until After all dissolved and cooled to room temperature, dilute to 1000mL.

[0034] (2) 10% ammonium chloride (NH 4 CL) solution: put 50g of ammonium chloride (analytical pure or chemically pure) in a 1L polyethylene bucket, add 1000mL of distilled water, and shake fully to completely dissolve the ammonium chloride.

[0035] (3) 1.8% sodium hydroxide (containing triethanolamine) solution: Weigh 18g of sodium hydroxide (NaOH) of analytical grade), put it into a clean and dry 1000mL beaker, add 1000mL of distilled water to dissolve it completely, and wait for the solution to cool to room temperature Finally, add 2 mL of triethanolamine (analytical grade), stir well and store...

Embodiment 2

[0047] (1) Select and use about 300g of representative steel slag soil in six typical sections of Yewu Expressway Project, and put it into a beaker;

[0048] (2) Referring to steps (2) and (3) in Example 1, measure the consumption of disodium EDTA;

[0049] (3) Use the standard curve obtained in Example 1 to determine the steel slag content of the soil sample according to the consumption of disodium EDTA.

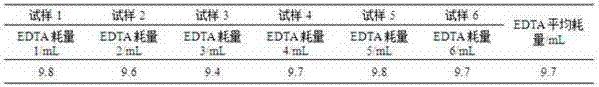

[0050] Table 2 EDTA consumption

[0051]

[0052] The measured EDTA consumption is 9.7mL, and the steel slag content is 8.1wt%.

Embodiment 3

[0054] (1) Prepare 5 steel slag soil samples with a steel slag content of 8.0wt% in the laboratory, and the moisture content is the same as that of the on-site paving;

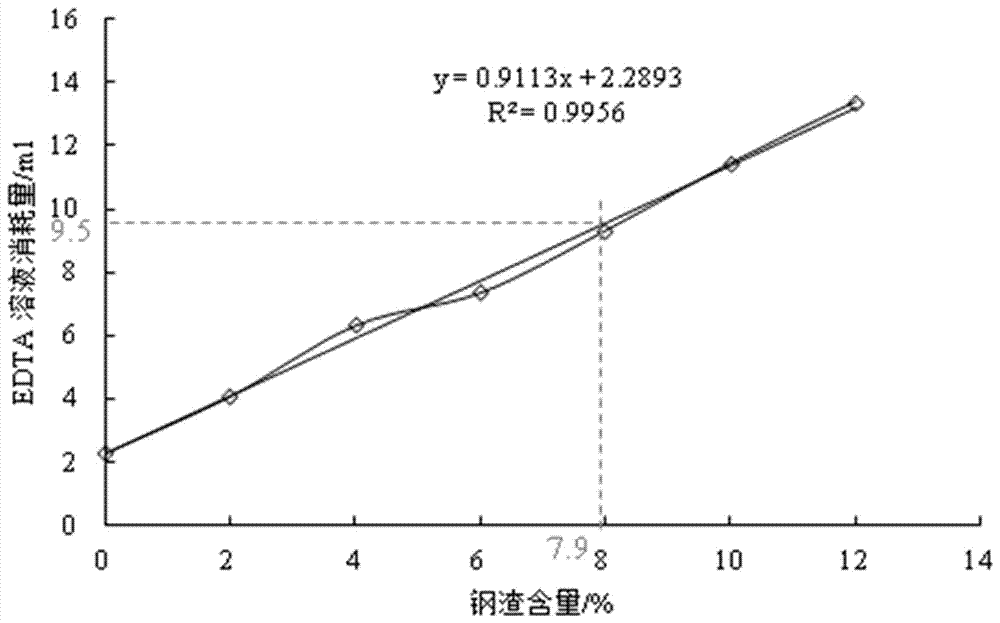

[0055] (2) Referring to steps (2) and (3) in Example 1, the average consumption of disodium EDTA standard solution was measured to be about 9.5 mL.

[0056] Table 3 EDTA consumption

[0057]

[0058] Compared with the standard curve, it is found that the content of steel slag is about 7.9wt%, which meets the relevant requirements for the detection accuracy of paving in the steel slag-stabilized soil test section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com