Refrigerator and pipeline assembly used for refrigerator

A technology for piping components and refrigerators, applied in household refrigerators, applications, household appliances, etc., can solve the problems of increased heat load of refrigerators and increased power consumption of refrigerators, and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

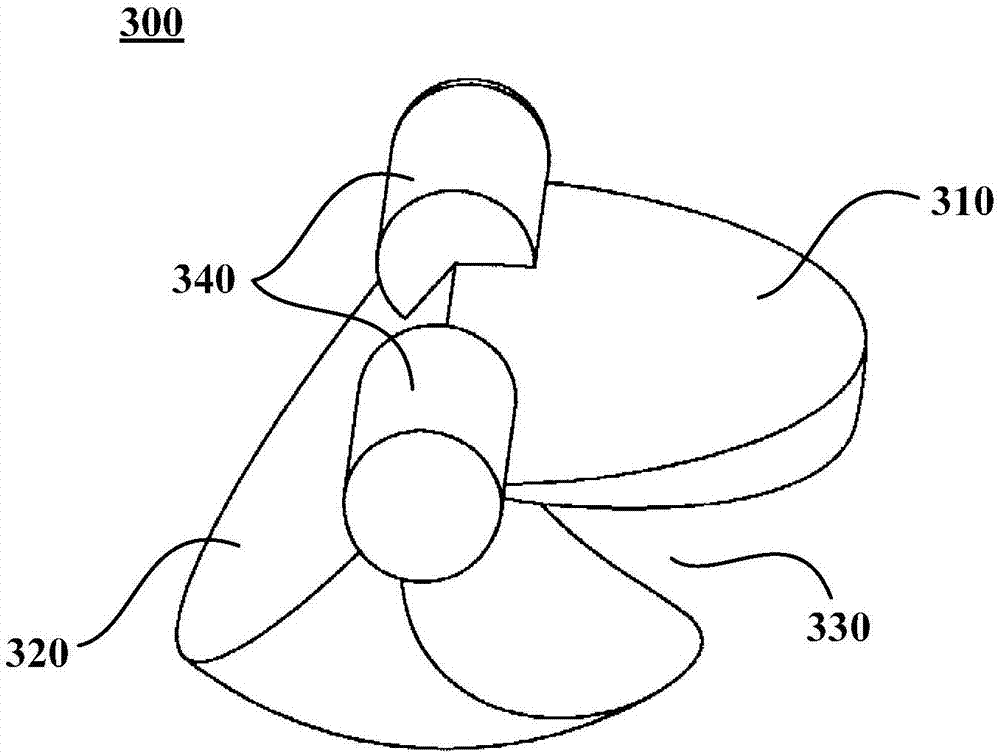

[0031] figure 1 is a schematic assembly diagram of a duct assembly according to one embodiment of the present invention. combine figure 1 and figure 2 As shown, the embodiment of the present invention provides a pipeline assembly 10 for a refrigerator, which can be arranged on some pipelines of the refrigerator, especially can be arranged on the water inlet or drain of the pipeline. Specifically, the pipe assembly 10 may include a first liquid feeding pipe section 100 , a second liquid feeding pipe section 200 and a sealing rotor 300 . Wherein, the first liquid feeding pipe section 100 can be used to transport liquid, which can be connected with the water inlet or the water outlet of the pipe, and can also be a part of the pipe of the refrigerator. The second liquid-feeding pipe section 200 can be connected to the liquid inlet of the first liquid-feeding pipe section 100. In the figure, it is connected to the upper end of the first liquid-feeding pipe section 100, for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com